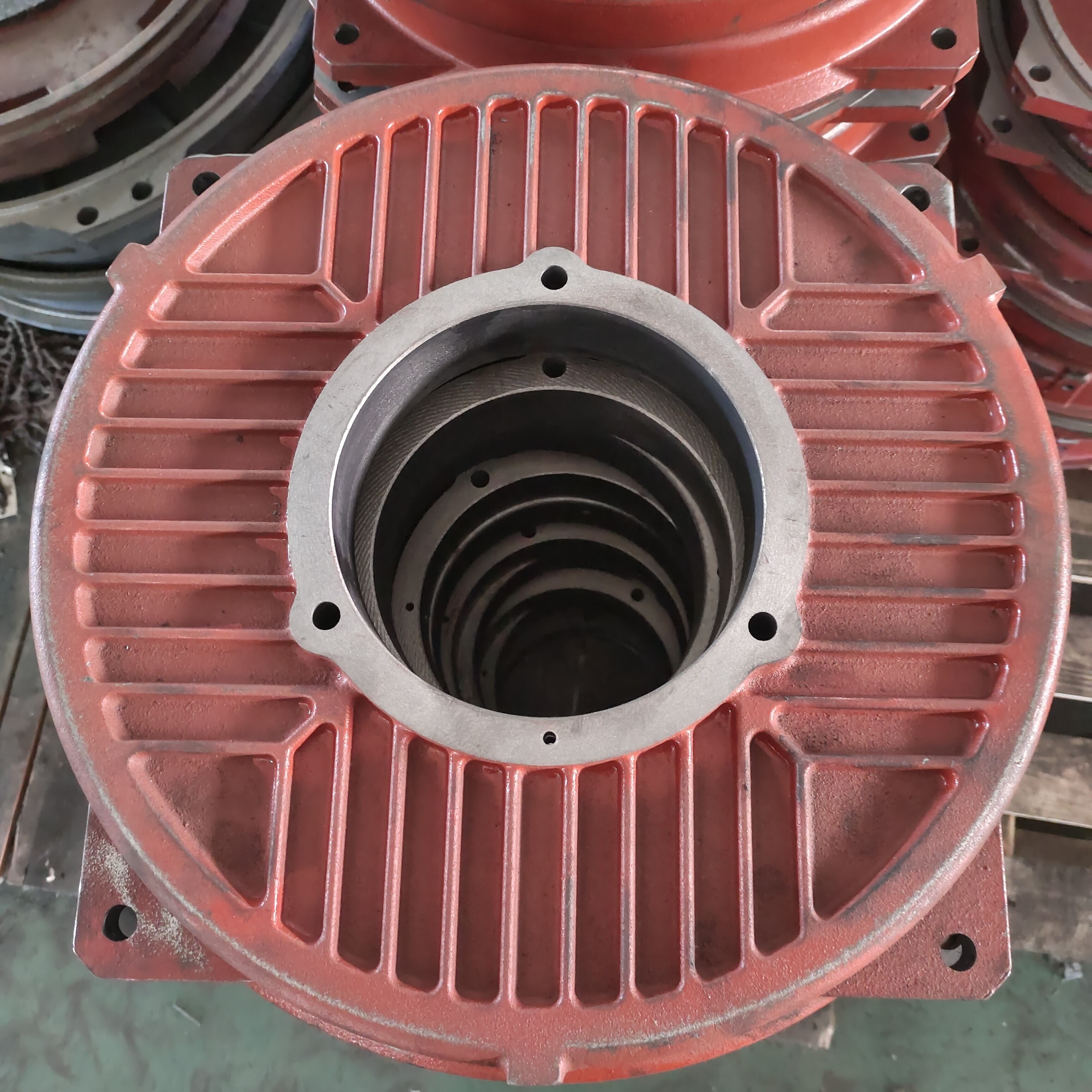

safe end plate

The safe end plate represents a critical component in modern industrial piping systems, serving as a protective barrier that ensures operational safety and system integrity. This specialized engineering solution functions as a transition element between different pipe materials or systems, providing a secure connection point while maintaining structural stability under various pressure and temperature conditions. The safe end plate incorporates advanced metallurgical properties and precision manufacturing techniques to deliver reliable performance in demanding industrial environments. Its primary function involves creating a leak-proof seal between pipe sections while accommodating thermal expansion and contraction cycles that occur during normal operation. The technological features of the safe end plate include corrosion-resistant materials, precision-machined surfaces, and standardized dimensions that ensure compatibility with existing infrastructure. These plates undergo rigorous quality testing procedures to meet international safety standards and regulatory requirements. The applications for safe end plates span across multiple industries including oil and gas processing, chemical manufacturing, power generation facilities, and water treatment systems. In petrochemical refineries, the safe end plate provides essential protection against hazardous material leakage while maintaining system pressure integrity. Power plants utilize these components to ensure safe steam and coolant circulation throughout complex piping networks. The design methodology behind each safe end plate incorporates stress analysis calculations and material selection protocols that account for specific operating parameters such as pressure ratings, temperature ranges, and chemical compatibility requirements. Modern manufacturing processes employ computer-controlled machining centers and automated quality inspection systems to produce safe end plates with consistent dimensional accuracy and surface finish quality.