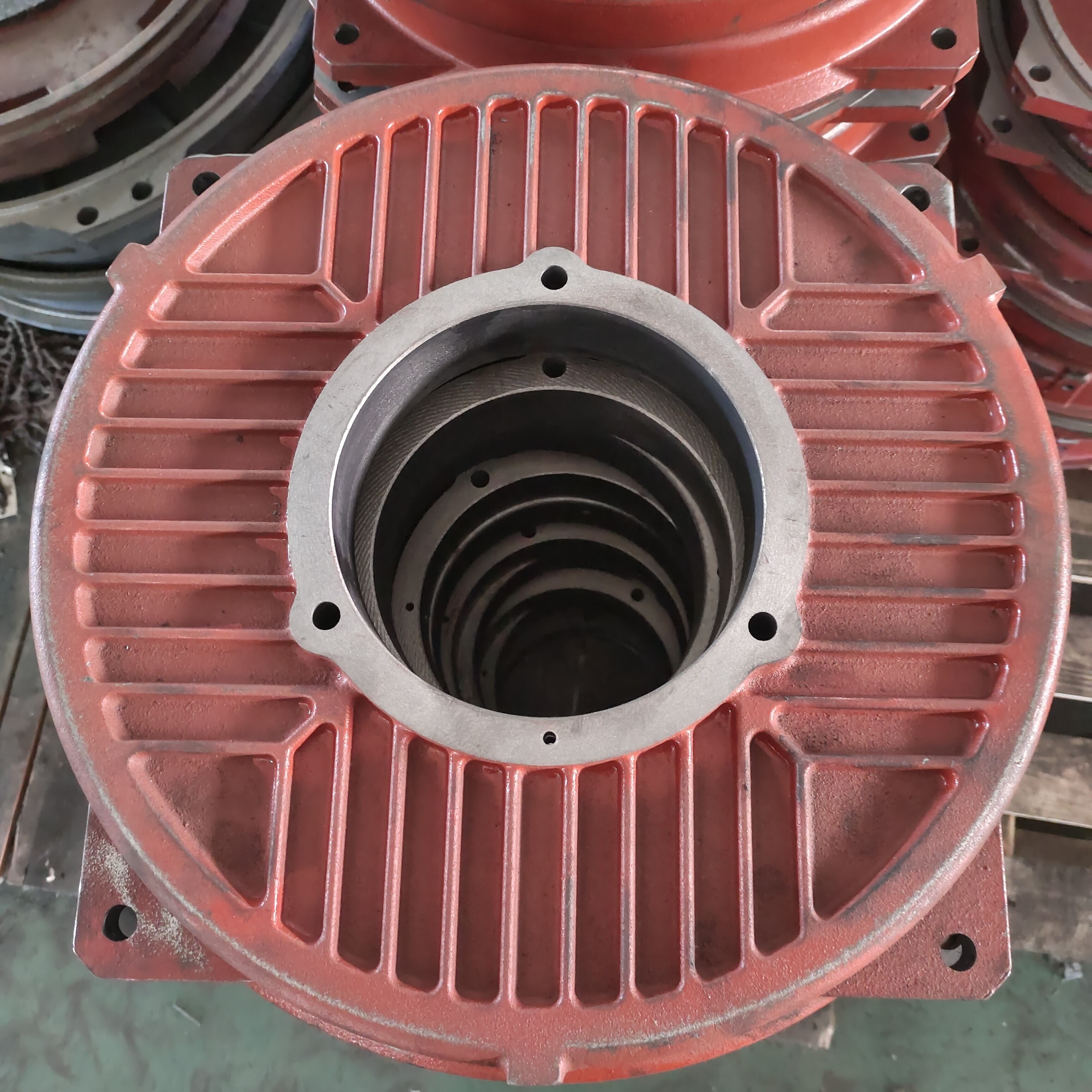

newest end plate

The newest end plate represents a revolutionary advancement in industrial component design, offering unprecedented performance and reliability across diverse manufacturing applications. This cutting-edge component serves as a critical interface between multiple system elements, providing structural integrity while ensuring optimal operational efficiency. The newest end plate incorporates advanced materials engineering and precision manufacturing techniques to deliver superior durability and extended service life. Its primary functions include load distribution, thermal management, vibration dampening, and electrical isolation where required. The technological features of this newest end plate encompass enhanced corrosion resistance through specialized coating technologies, improved dimensional stability under extreme temperature variations, and optimized weight-to-strength ratios. Manufacturing precision has been elevated through computer-controlled machining processes, ensuring consistent quality and perfect fitment across production runs. The newest end plate design integrates modular compatibility features, allowing seamless integration with existing systems while providing upgrade pathways for future enhancements. Applications span across automotive manufacturing, aerospace systems, industrial machinery, renewable energy installations, and heavy equipment operations. The versatility of this newest end plate makes it suitable for both original equipment manufacturing and retrofit applications. Quality control measures include comprehensive testing protocols that validate performance under extreme conditions, ensuring reliability in demanding operational environments. The newest end plate demonstrates exceptional resistance to mechanical stress, chemical exposure, and environmental factors that traditionally compromise component longevity. Advanced surface treatments provide additional protection against wear, while specialized gasket interfaces ensure leak-proof sealing in fluid handling applications.