Understanding the Mechanics Behind Asynchronous Motor Operation

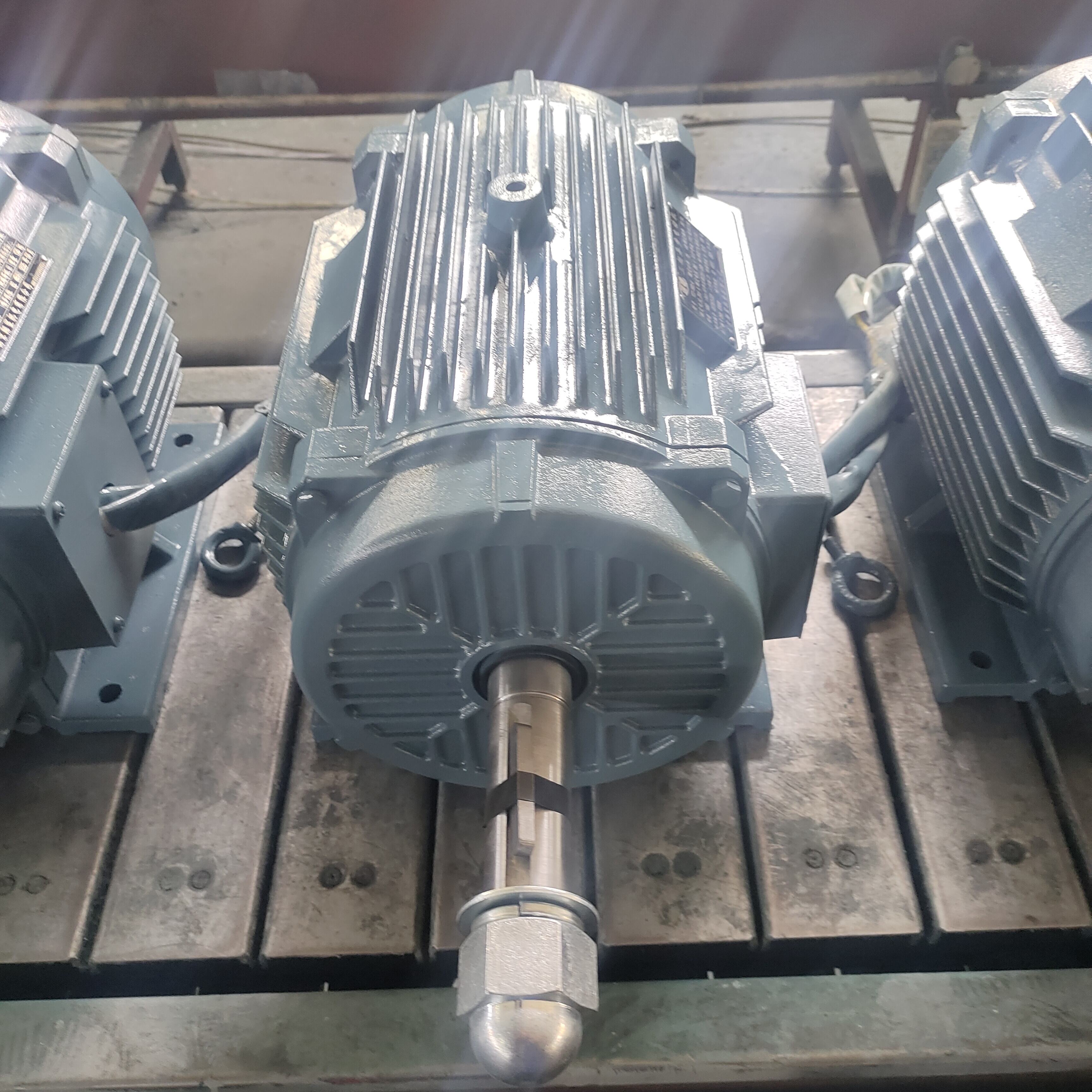

Asynchronous electric motors, also known as induction motors, serve as the backbone of industrial machinery and equipment worldwide. These powerful workhorses convert electrical energy into mechanical energy through electromagnetic induction, operating with remarkable efficiency when properly maintained. Their widespread adoption across various industries stems from their robust design, cost-effectiveness, and relatively straightforward maintenance requirements.

The fundamental principle behind an asynchronous electric motor involves creating a rotating magnetic field in the stator that induces current in the rotor, generating torque. This process occurs without the need for physical electrical connections to the rotor, making these motors particularly reliable and durable. However, like all mechanical systems, they can develop issues that require attention and repair.

Essential Components and Their Functions

Stator Assembly and Windings

The stator forms the stationary part of an asynchronous electric motor, consisting of laminated steel cores with embedded copper windings. These windings, when energized with three-phase power, create the rotating magnetic field essential for motor operation. Regular inspection of stator windings helps identify potential issues such as insulation breakdown or overheating before they lead to major failures.

Maintaining proper stator alignment and ensuring clean, debris-free windings significantly extends motor life. Environmental factors like moisture, dust, and excessive heat can compromise winding integrity, making regular cleaning and protection crucial for optimal performance.

Rotor Construction and Common Issues

The rotor, the motor's rotating component, features carefully designed conductor bars and end rings forming a cage-like structure. This squirrel-cage design allows for robust operation but can suffer from various issues including broken bars, end ring damage, or bearing failures. Understanding rotor dynamics helps in early problem detection and prevention of catastrophic failures.

Regular monitoring of rotor performance through vibration analysis and temperature measurements provides valuable insights into potential problems. Early intervention when anomalies are detected can prevent costly downtime and extensive repairs.

Identifying and Diagnosing Motor Problems

Electrical Fault Detection

Electrical faults in asynchronous electric motors often manifest through symptoms like excessive heat generation, unusual noises, or performance irregularities. Common electrical issues include phase imbalance, insulation failure, and voltage problems. Using diagnostic tools such as multimeters and insulation testers helps pinpoint specific electrical problems.

Modern monitoring systems can provide real-time data on motor performance, enabling predictive maintenance approaches. This proactive stance helps prevent unexpected failures and optimizes maintenance scheduling.

Mechanical Issue Assessment

Mechanical problems typically involve bearing wear, shaft misalignment, or cooling system failures. These issues often produce distinctive symptoms like vibration patterns or unusual sounds. Regular mechanical inspections, including bearing condition assessment and alignment checks, are essential for maintaining motor reliability.

Implementing a systematic approach to mechanical maintenance, including proper lubrication schedules and alignment procedures, significantly reduces the likelihood of serious mechanical failures.

Preventive Maintenance Strategies

Routine Inspection Protocols

Developing comprehensive inspection protocols for asynchronous electric motors ensures consistent monitoring and maintenance. These protocols should include regular checks of bearing condition, winding temperature, vibration levels, and insulation resistance. Documentation of inspection findings helps track motor health trends over time.

Training maintenance personnel in proper inspection techniques and providing them with appropriate tools and equipment ensures effective preventive maintenance implementation. Regular updates to maintenance procedures based on observed patterns and emerging technologies help optimize motor care.

Performance Monitoring Systems

Modern monitoring technologies offer sophisticated ways to track asynchronous electric motor performance. These systems can measure parameters like current draw, temperature, vibration, and speed in real-time. Analysis of this data helps identify developing problems before they cause failures.

Integration of monitoring systems with maintenance management software enables automated alerts and scheduled maintenance based on actual motor condition rather than fixed time intervals. This approach optimizes maintenance resources while maximizing motor reliability.

Troubleshooting and Repair Techniques

Emergency Response Procedures

When an asynchronous electric motor fails, having established emergency response procedures helps minimize downtime and prevent secondary damage. These procedures should include safety protocols, diagnostic steps, and clear decision-making guidelines for repair versus replacement.

Maintaining an inventory of critical spare parts and establishing relationships with reliable repair services ensures quick response to emergencies. Documentation of emergency procedures and regular staff training prepare organizations for efficient problem resolution.

Repair Best Practices

Proper repair techniques for asynchronous electric motors require attention to detail and adherence to manufacturer specifications. This includes using appropriate replacement parts, following correct assembly procedures, and performing thorough testing after repairs. Quality control measures ensure repairs meet required standards and restore full motor functionality.

Documentation of repair procedures, including photographs and detailed notes, helps maintain repair quality and provides valuable reference material for future maintenance activities. Regular review and updates of repair practices ensure alignment with current industry standards.

Frequently Asked Questions

How often should an asynchronous electric motor undergo maintenance?

Regular maintenance intervals typically range from quarterly to annually, depending on operating conditions and motor criticality. However, continuous monitoring and condition-based maintenance may adjust these intervals based on actual motor performance and environmental factors.

What are the signs of impending motor failure?

Key warning signs include unusual noise or vibration, excessive heat generation, decreased performance, increased power consumption, and irregular starting behavior. Early detection of these symptoms through regular monitoring helps prevent catastrophic failures.

When should a motor be replaced rather than repaired?

Consider replacement when repair costs exceed 50-70% of new motor cost, when efficiency improvements justify the investment, or when the motor has undergone multiple major repairs. Age, availability of replacement parts, and critical application requirements also influence this decision.