Интеграция на напреднали технологии в материалите

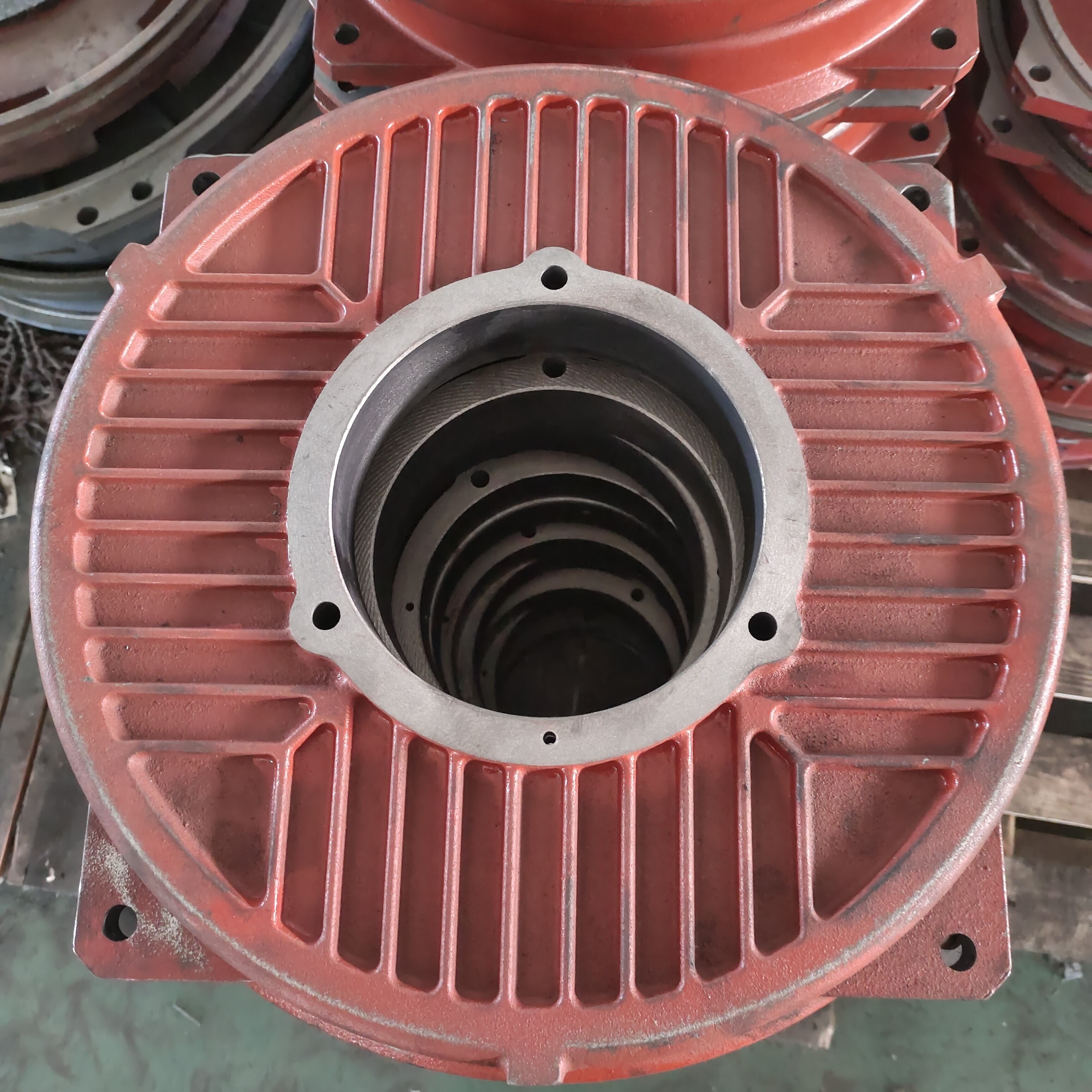

Най-новата краен плоча представя новаторска материална технология, която задава нови индустриални стандарти за надеждността и производителността на компонентите. Този революционен подход комбинира сплави от аерокосмическа класа със собствени повърхностни обработки, като създава компонент, който значително надминава традиционните решения. Най-новата краен плоча използва многослойна конструкция, при която всеки слой изпълнява специфични функционални цели, като допринася за общата структурна цялостност. Основният материал се състои от високопрочна стоманена сплав, която осигурява изключителна носеща способност, докато междинните слоеве включват съединения, устойчиви на корозия, които предпазват от химическо разграждане. Външната повърхност е със специализирано покритие, което увеличава устойчивостта на износване и осигурява самосмачаващи свойства, намалявайки триенето и удължавайки експлоатационния живот. Изборът на материала за най-новата краен плоча включва обширно тестване в различни околните условия, осигурявайки постоянна производителност при предизвикателни приложения. Напредналата металургия, използвана при производството на най-новата краен плоча, води до превъзходна устойчивост на умора, позволявайки на компонента да издържи милиони работни цикли без намаляване на производителността. Топлинните свойства на материалната композиция позволяват на най-новата краен плоча да запазва размерната стабилност при екстремни температурни колебания, предотвратявайки деформация или структурни повреди. Материалната технология включва и свойства срещу заключване (galling), които предотвратяват залепване по време на процесите на монтаж и демонтаж. Производствените процеси за най-новата краен плоча включват прецизни цикли на термична обработка, които оптимизират материалните свойства и гарантират последователно качество в рамките на производствените партиди. Мерките за контрол на качеството потвърждават, че всяка най-нова краен плоча отговаря на строгите изисквания за материални свойства чрез всеобхватни протоколи за тестване. Устойчивостта към околната среда, вградена в материалната технология, прави най-новата краен плоча подходяща за употреба на открито, където влагата, UV лъчението и химическите замърсители биха могли да компрометират по-слаби компоненти.