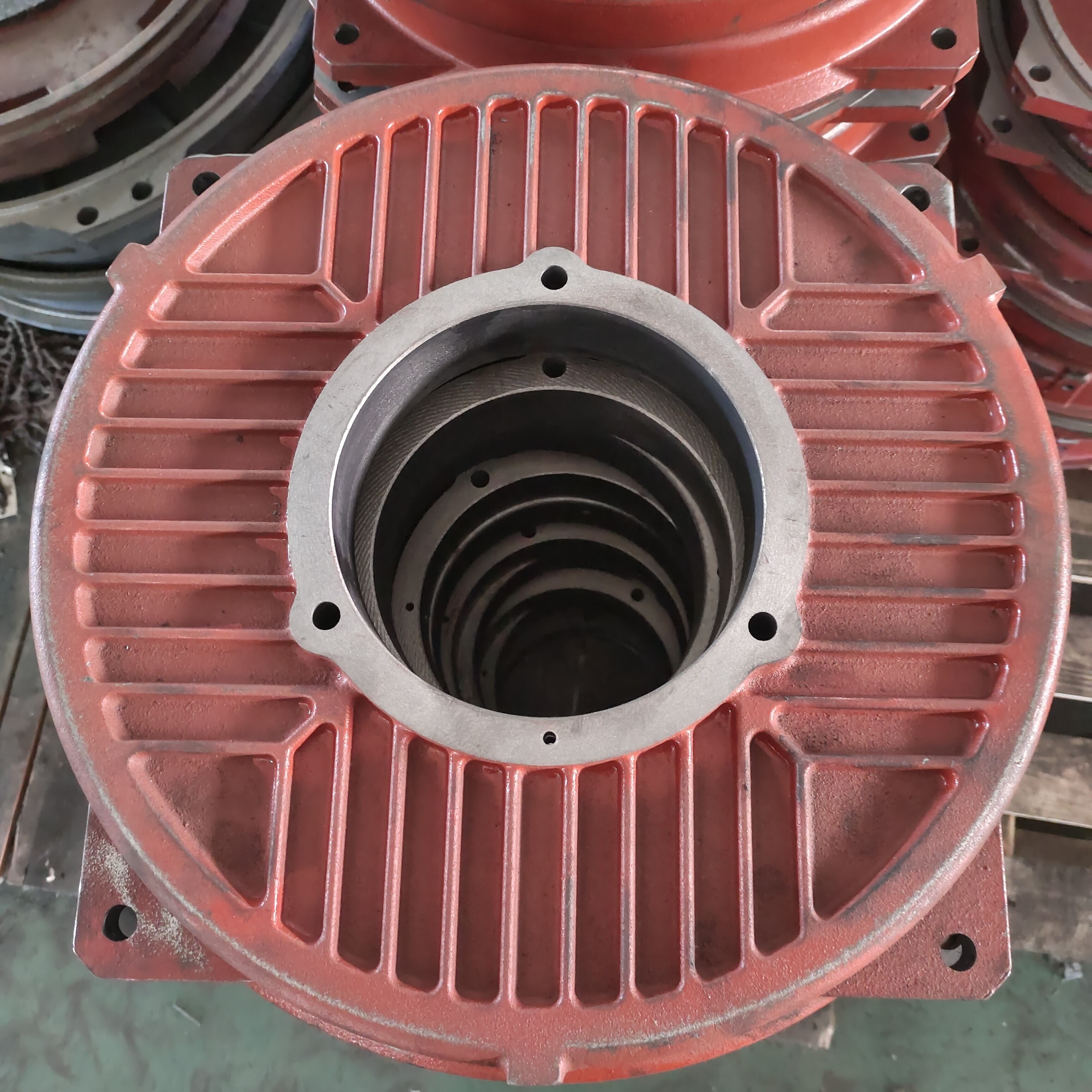

pelat hujung selamat

Pelat hujung selamat merupakan komponen kritikal dalam sistem perpaipan industri moden, berfungsi sebagai penghalang pelindung yang memastikan keselamatan operasi dan integriti sistem. Penyelesaian kejuruteraan khusus ini berfungsi sebagai elemen peralihan antara bahan atau sistem paip yang berbeza, menyediakan titik sambungan yang selamat sambil mengekalkan kestabilan struktur di bawah pelbagai keadaan tekanan dan suhu. Pelat hujung selamat menggabungkan sifat metalurgi maju dan teknik pembuatan tepat untuk memberikan prestasi yang boleh dipercayai dalam persekitaran industri yang mencabar. Fungsi utamanya melibatkan penciptaan kedap kebocoran antara bahagian paip sambil menampung kitaran pengembangan dan pengecutan haba yang berlaku semasa operasi biasa. Ciri teknologi pelat hujung selamat termasuk bahan rintang kakisan, permukaan dimesin dengan tepat, dan dimensi piawaian yang memastikan keserasian dengan infrastruktur sedia ada. Pelat ini menjalani prosedur ujian kualiti yang ketat untuk memenuhi piawaian keselamatan antarabangsa dan keperluan peraturan. Aplikasi pelat hujung selamat merangkumi pelbagai industri termasuk pemprosesan minyak dan gas, pembuatan kimia, kemudahan penjana kuasa, dan sistem rawatan air. Dalam kilang petrokimia, pelat hujung selamat memberikan perlindungan penting terhadap kebocoran bahan berbahaya sambil mengekalkan integriti tekanan sistem. Stesen kuasa menggunakan komponen ini untuk memastikan peredaran stim dan penyejuk yang selamat di seluruh rangkaian paip yang kompleks. Metodologi reka bentuk setiap pelat hujung selamat menggabungkan pengiraan analisis tekanan dan protokol pemilihan bahan yang mengambil kira parameter operasi tertentu seperti kadar tekanan, julat suhu, dan keperluan keserasian kimia. Proses pembuatan moden menggunakan pusat pemesinan terkawal komputer dan sistem pemeriksaan kualiti automatik untuk menghasilkan pelat hujung selamat dengan ketepatan dimensi dan kualiti permukaan yang konsisten.