安全なエンドプレート

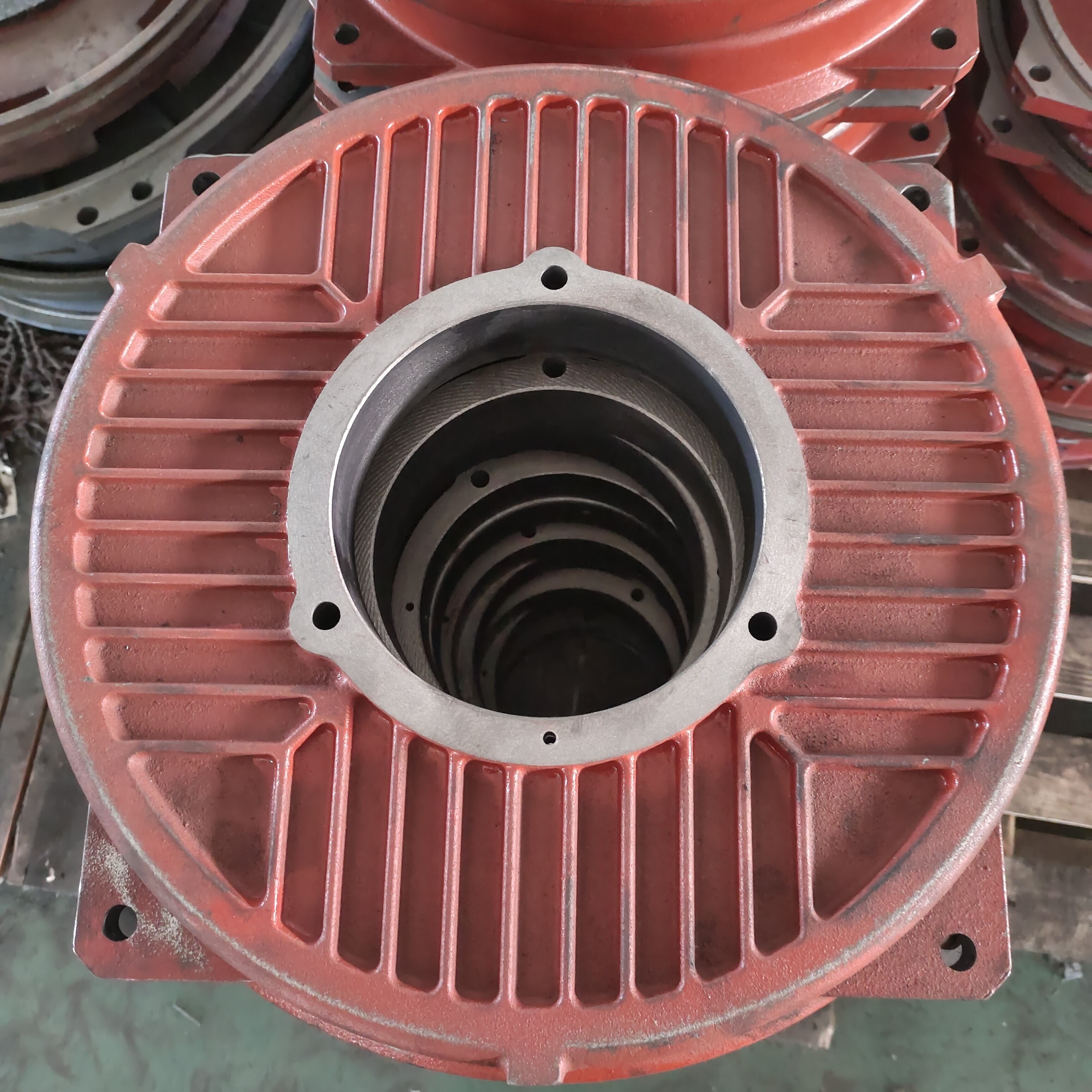

安全エンドプレートは、現代の産業用配管システムにおいて重要な構成部品であり、作業の安全性とシステムの完全性を確保するための保護バリアとして機能します。この専門的なエンジニアリングソリューションは、異なる配管材料やシステム間の接続部としての役割を果たし、さまざまな圧力および温度条件下でも構造的安定性を維持しながら、確実な接続点を提供します。安全エンドプレートは、高度な冶金特性と精密製造技術を組み合わせることで、過酷な工業環境下でも信頼性の高い性能を発揮します。その主な機能は、パイプ区間間に漏れのないシールを形成するとともに、通常の運転中に発生する熱膨張および収縮サイクルに対応することです。安全エンドプレートの技術的特徴には、耐腐食性材料、高精度に機械加工された表面、既存のインフラと互換性を保証する標準化された寸法が含まれます。これらのプレートは、国際的な安全基準および規制要件を満たすために厳格な品質試験プロセスを経ています。安全エンドプレートの用途は、石油・ガス処理、化学製品製造、発電所、水処理システムなど、複数の産業分野にわたります。石油化学 refinery では、安全エンドプレートは危険物質の漏洩から保護する上で不可欠でありながら、システム内の圧力の完全性を維持します。発電所では、複雑な配管ネットワークを通じて蒸気および冷却剤が安全に循環するようにするためにこれらの部品が使用されます。各安全エンドプレートの設計手法には、圧力クラス、温度範囲、化学的適合性といった特定の運転パラメータを考慮した応力解析計算および材料選定プロトコルが組み込まれています。現代の製造工程では、コンピュータ制御のマシニングセンターや自動品質検査システムが採用され、寸法精度および表面仕上げ品質を一貫して高レベルに保ちながら安全エンドプレートを生産しています。