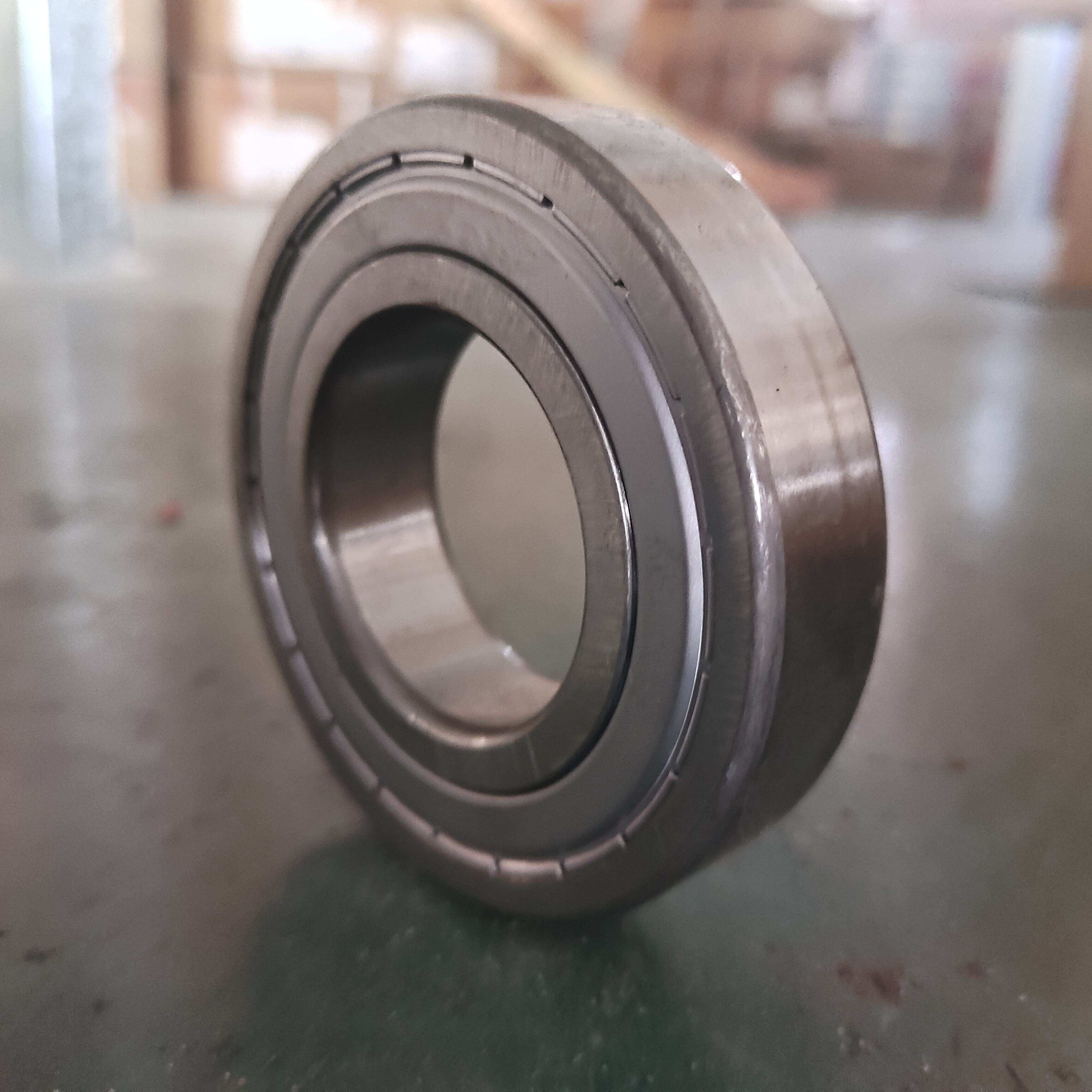

latest design rolling bearings

The latest design rolling bearings represent a revolutionary advancement in mechanical engineering, incorporating cutting-edge materials science and precision manufacturing techniques to deliver superior performance across diverse industrial applications. These modern bearing solutions feature enhanced load-carrying capacity, improved durability, and optimized efficiency that significantly surpass traditional bearing designs. The latest design rolling bearings utilize advanced steel alloys, ceramic hybrid elements, and specialized surface treatments that create smoother operation and extended service life. These bearings incorporate innovative cage designs manufactured from high-performance polymers or lightweight metals that reduce friction and minimize wear during operation. The sealing systems in the latest design rolling bearings employ advanced elastomer compounds and labyrinth seals that provide exceptional protection against contamination while maintaining optimal lubrication retention. Precision manufacturing processes ensure consistent dimensional accuracy and surface finish quality, enabling these bearings to operate effectively under extreme conditions including high temperatures, heavy loads, and corrosive environments. The latest design rolling bearings feature optimized internal geometry that distributes stress more evenly across load-bearing surfaces, reducing fatigue and extending operational life. These bearings accommodate both radial and axial loads with remarkable efficiency, making them suitable for complex mechanical systems. Advanced lubrication technologies, including solid lubricants and specialized greases, are integrated into the latest design rolling bearings to reduce maintenance requirements and improve performance consistency. The manufacturing process incorporates computer-aided design optimization and advanced quality control systems that ensure each bearing meets stringent performance standards. These innovations make the latest design rolling bearings essential components for modern machinery across automotive, aerospace, industrial equipment, and renewable energy sectors, where reliability and performance are critical success factors.