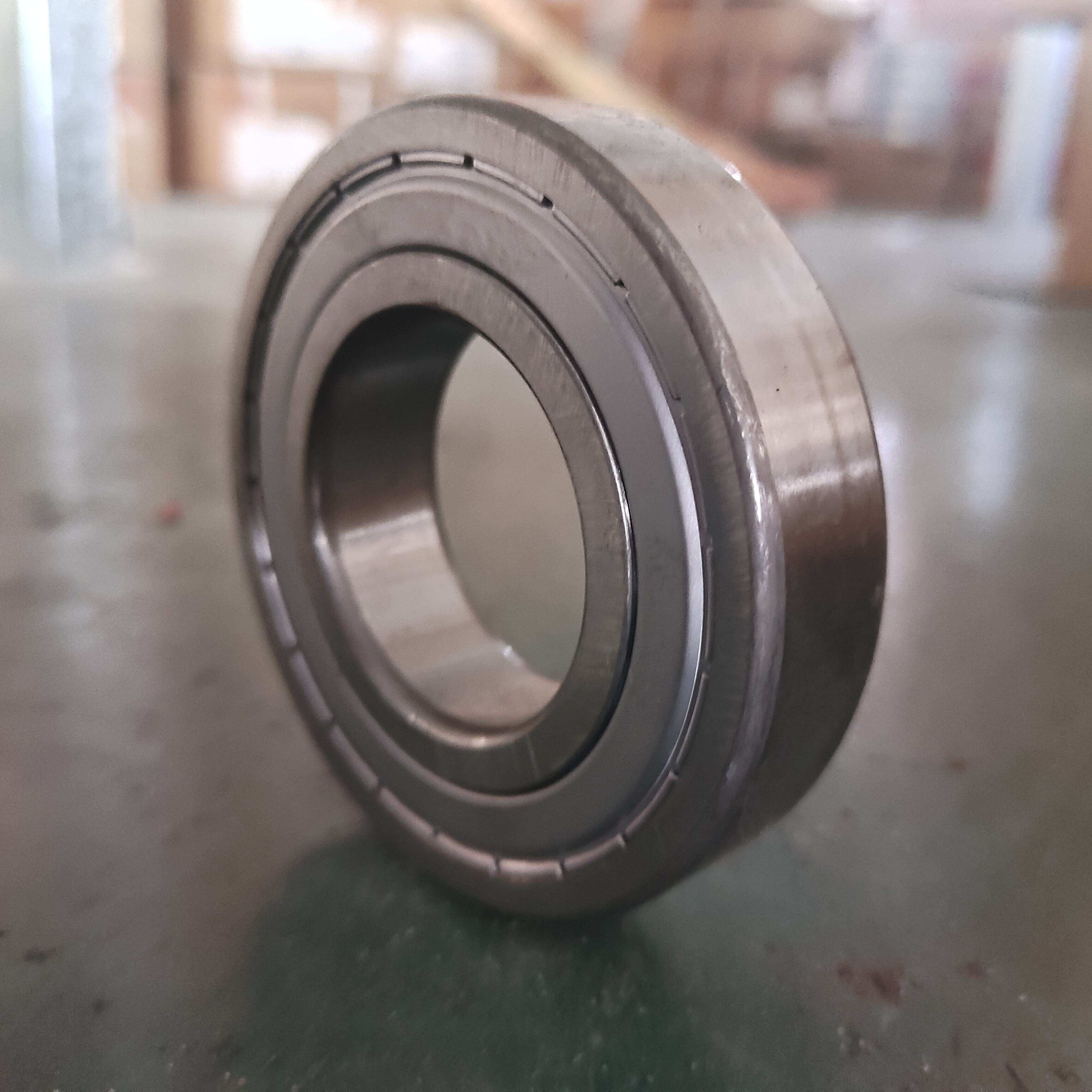

wholesale bearing

Wholesale bearing represents a comprehensive solution for businesses seeking cost-effective, high-quality bearing components in bulk quantities. These mechanical elements serve as crucial intermediaries between moving parts in machinery, facilitating smooth rotation while reducing friction and supporting various loads. The wholesale bearing market encompasses diverse types including ball bearings, roller bearings, thrust bearings, and specialized variants designed for specific industrial applications. Modern wholesale bearing products feature advanced materials such as chrome steel, stainless steel, and ceramic compositions that enhance durability and performance across demanding operational environments. The technological sophistication of contemporary wholesale bearing systems incorporates precision manufacturing processes, including computer-controlled machining and quality assurance protocols that ensure dimensional accuracy within micron tolerances. These components utilize advanced lubrication systems, protective seals, and optimized internal geometries that maximize operational efficiency while minimizing maintenance requirements. Applications for wholesale bearing products span numerous industries including automotive manufacturing, aerospace engineering, industrial machinery, renewable energy systems, and heavy equipment operations. The versatility of wholesale bearing solutions enables their integration into conveyor systems, motor assemblies, pumps, compressors, and countless other mechanical applications where rotational motion occurs. Distribution networks for wholesale bearing products typically involve specialized suppliers who maintain extensive inventories, provide technical support, and offer customized solutions tailored to specific customer requirements. The global wholesale bearing market continues expanding due to increasing industrial automation, infrastructure development, and technological advancement across manufacturing sectors. Quality standards for wholesale bearing products adhere to international specifications including ISO, ABEC, and DIN classifications that guarantee consistent performance and interchangeability across different manufacturers and applications.