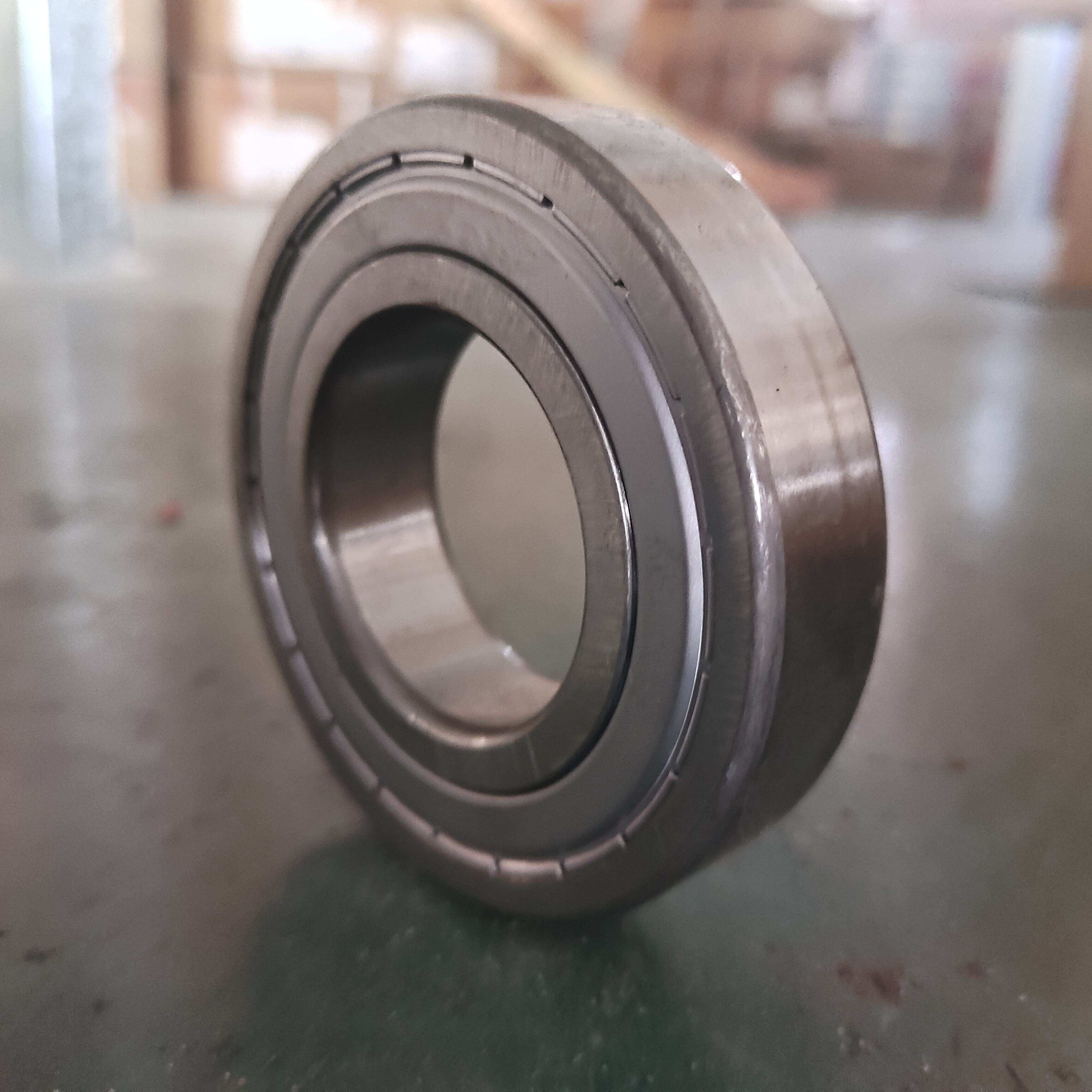

high quality bearing

A high quality bearing represents the pinnacle of precision engineering, serving as a fundamental mechanical component that enables smooth rotational or linear movement between machine parts while minimizing friction and wear. These sophisticated devices operate on the principle of rolling or sliding contact, utilizing carefully manufactured balls, rollers, or other elements to reduce resistance and maintain optimal performance under various operating conditions. The primary function of a high quality bearing involves supporting loads, controlling motion, and reducing friction between moving components in mechanical systems. Modern high quality bearing designs incorporate advanced materials such as chrome steel, stainless steel, ceramic, and specialized alloys that deliver exceptional durability and performance characteristics. The technological features of premium bearings include precision-ground raceways, optimized internal geometry, advanced lubrication systems, and enhanced sealing mechanisms that protect against contamination. Manufacturing processes for high quality bearing production involve stringent quality control measures, including dimensional accuracy verification, surface finish optimization, and comprehensive testing protocols. These bearings find extensive applications across diverse industries including automotive, aerospace, industrial machinery, medical equipment, renewable energy systems, and consumer appliances. In automotive applications, high quality bearing assemblies support wheel hubs, transmissions, engines, and steering systems, ensuring reliable operation throughout the vehicle's lifespan. Aerospace applications demand bearings that can withstand extreme temperatures, high speeds, and challenging environmental conditions while maintaining precise performance standards. Industrial machinery relies on high quality bearing solutions for conveyor systems, pumps, compressors, and manufacturing equipment where operational reliability directly impacts productivity. The bearing's load-carrying capacity, speed ratings, and environmental resistance characteristics determine its suitability for specific applications, making proper selection crucial for optimal system performance and longevity.