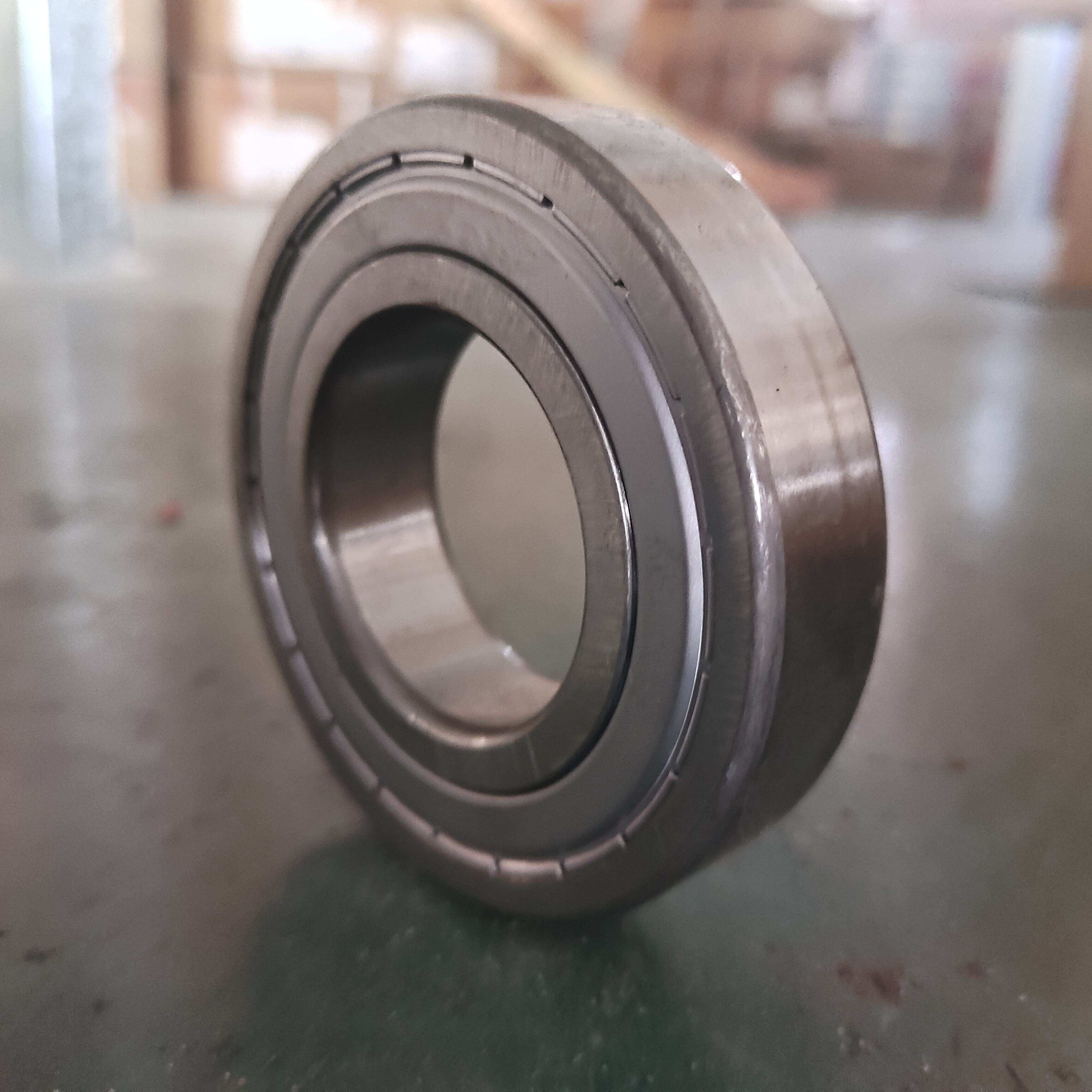

מפרק באיכות גבוהה

שסתים באיכות גבוהה מייצגים את שיא ההנדסה המדויקת, ומשמשים כרכיב מכני בסיסי המאפשר תנועה סיבובית או ליניארית חלקה בין חלקים מכניים תוך מינימום של חיכוך ובלאי. התקנים מתוחכמים אלו פועלים על פי עיקרון של מגע גלגול או החלקה, תוך שימוש בכדורים, גלילים או רכיבים אחרים שמיוצרים במדויק כדי להפחית את ההתנגדות ולשמור על ביצועים אופטימליים תחת מגוון תנאים של פעולה. הפונקציה העיקרית של שסתים באיכות גבוהה כוללת תמיכה במשקולות, בקרת תנועה והפחתת חיכוך בין רכיבים נעים במערכות מכניות. דוגמיות שסתים מודרניות כוללות חומרים מתקדמים כגון פלדת כרום, פלדת אל-חלד, חומר קרמי וсплавים מיוחדים שמציעים עמידות ומאפייני ביצועים יוצאי דופן. התכונות הטכנולוגיות של שסתים מתקדמים כוללות מסילות מדויקות, גאומטריה פנימית מותאמת, מערכות שימון מתקדמות ומנגנוני איטום משופרים המגנים מפני זיהום. תהליכי ייצור של שסתים באיכות גבוהה כוללים אמצעי בקרת איכות קפדניים, הכוללים אימות דיוק ממדי, אופטימיזציה של גימור המשטח ופרוטוקולי בדיקה מקיפים. שסתים אלו משמשים בתחומים רבים, ביניהם תעשיית הרכב, תעשייה אווירית, מכונות תעשייתיות, ציוד רפואי, מערכות אנרגיה מתחדשת ומכשירי צריכה. ביישומי רכב, קבוצות שסתים באיכות גבוהה תומכות במרכזי גלגלים, תיבת הילוכים, מנועים ומערכות היגוי, ומבטיחות פעילות אמינה לאורך כל מחזור החיים של הרכב. ביישומים אוויריים נדרשים שסתים שיכולים לעמוד בדרגות חום קיצוניות, מהירויות גבוהות ותנאים סביבתיים קשים, תוך שמירה על תקנים מדויקים של ביצועים. מכונות תעשייתיות מסתמכות על פתרונות שסתים באיכות גבוהה למערכות מסועים, משאבות, דחסים וציוד ייצור, שבהם אמינות פעולה משפיעה ישירות על תפוקה. היכולת של השסתים לשאת משקל, דירוגי המהירות ומאפייני עמידות לסביבה קובעים את התאימותם ליישומים מסוימים, מה שהופך לבחירה הנכונה חשובה לביצועים אופטימליים ולחזקות המערכת.