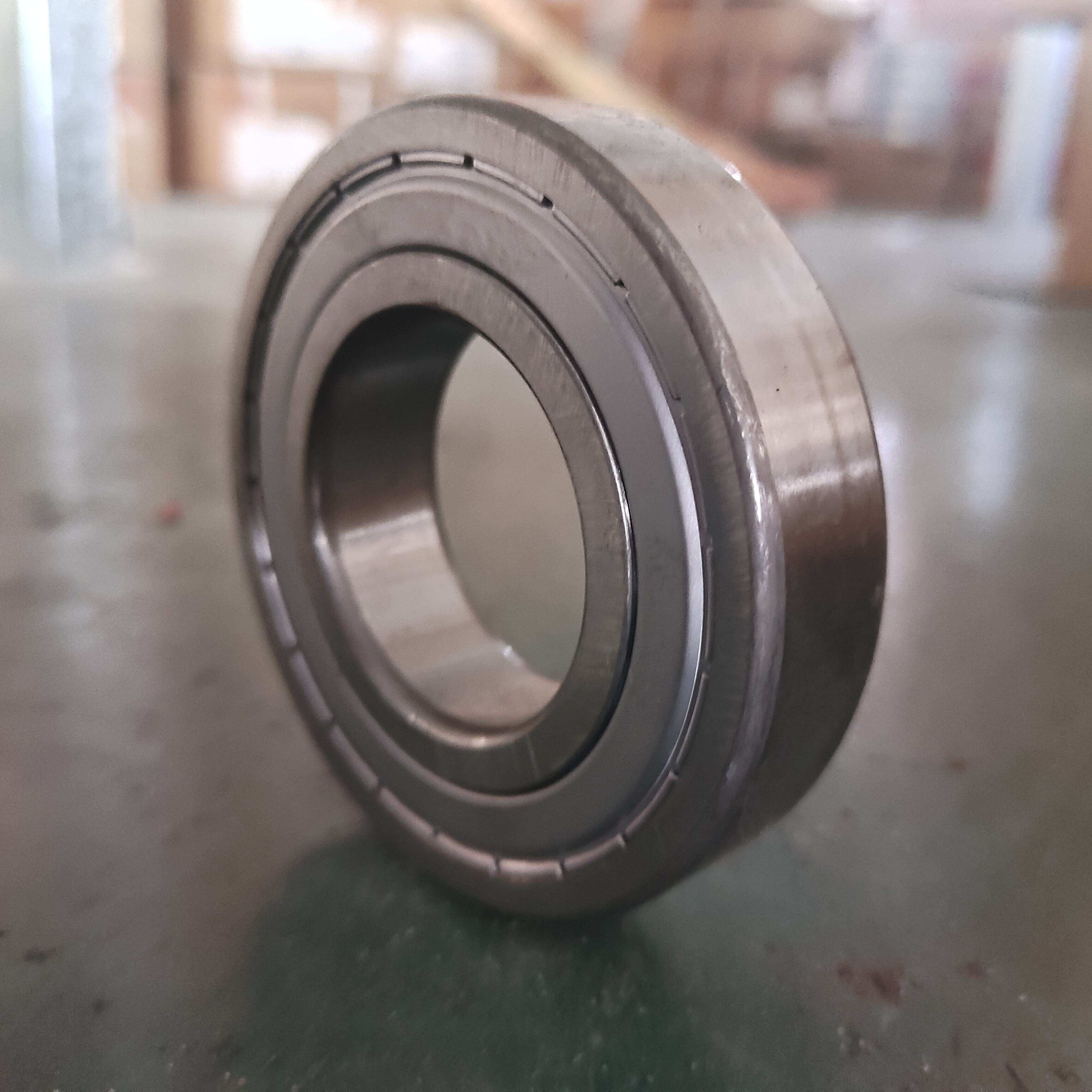

advanced bearing

Advanced bearing technology represents a revolutionary leap in mechanical engineering, offering superior performance characteristics that transform how rotating machinery operates across diverse industries. These precision-engineered components serve as critical interface points between moving parts, facilitating smooth rotation while minimizing friction and energy loss. An advanced bearing incorporates cutting-edge materials science, sophisticated manufacturing processes, and innovative design principles to deliver exceptional durability and operational efficiency. The primary functions encompass load distribution, rotational support, vibration dampening, and thermal management within mechanical systems. Technological features include enhanced surface treatments, optimized geometry configurations, advanced lubrication systems, and intelligent monitoring capabilities that provide real-time performance data. Manufacturing processes utilize high-grade steel alloys, ceramic composites, and specialized coatings that resist wear, corrosion, and extreme temperature variations. The precision manufacturing ensures tight tolerances, consistent quality, and reliable performance under demanding operational conditions. Applications span across automotive systems, aerospace components, industrial machinery, renewable energy equipment, robotics, medical devices, and heavy construction equipment. In automotive applications, advanced bearing technology improves fuel efficiency, reduces maintenance requirements, and enhances overall vehicle reliability. Aerospace implementations demand exceptional weight-to-strength ratios and performance consistency in extreme environmental conditions. Industrial machinery benefits from extended operational life, reduced downtime, and improved productivity through enhanced bearing performance. The technology addresses critical challenges in modern engineering by providing solutions for high-speed operations, heavy load capacity, contamination resistance, and extended service intervals. Advanced bearing systems integrate seamlessly with smart manufacturing environments, offering predictive maintenance capabilities and performance optimization features that reduce total cost of ownership while maximizing operational efficiency.