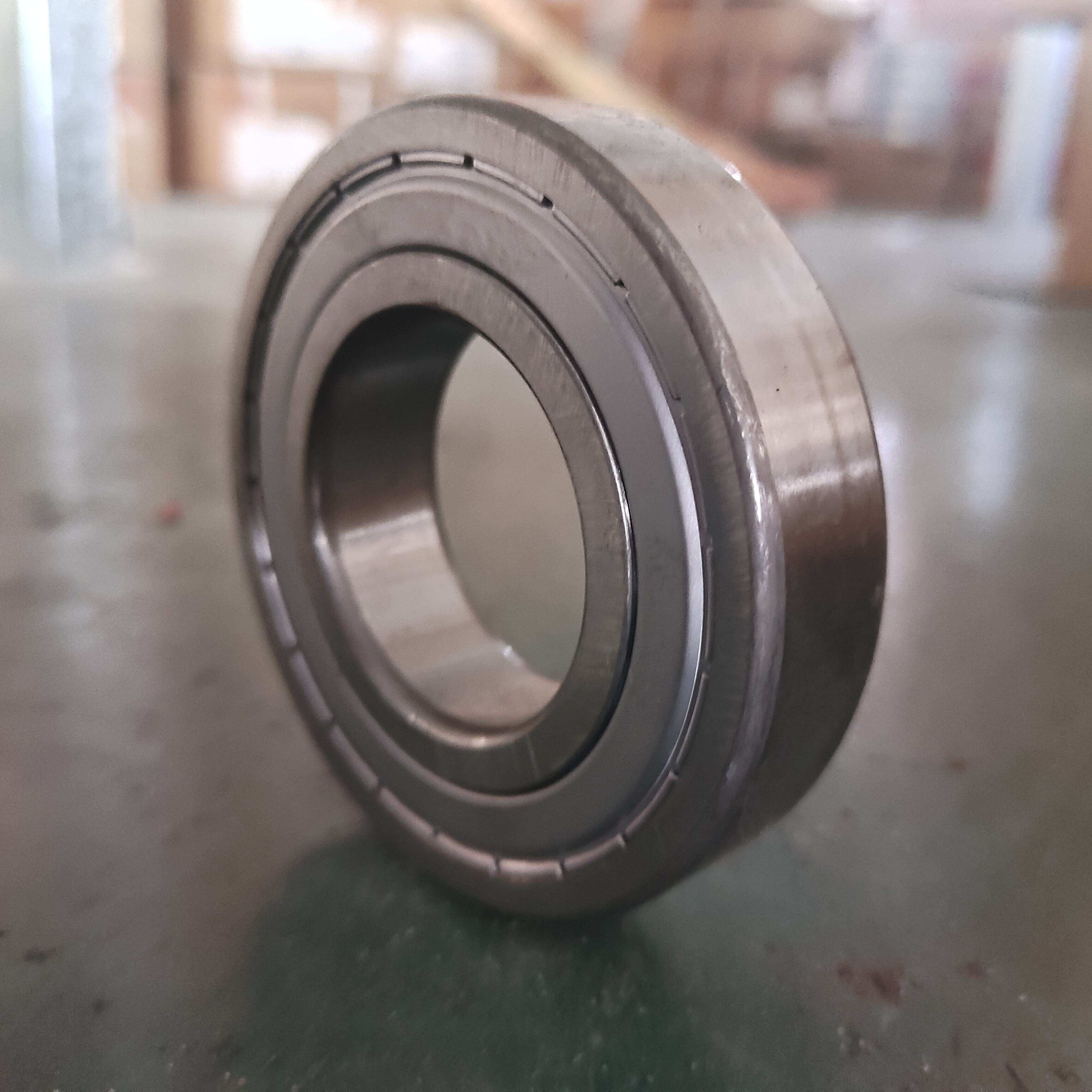

low price bearing

Low price bearings represent a revolutionary approach to mechanical engineering solutions, delivering exceptional performance without the premium cost typically associated with high-quality components. These bearings are engineered to provide reliable rotational support for various mechanical applications while maintaining affordability for businesses and individual consumers. A low price bearing incorporates essential functions including load distribution, friction reduction, and rotational support across diverse industrial and commercial settings. The primary technological features of low price bearings include precision manufacturing techniques that optimize material usage without compromising structural integrity. Advanced metallurgy processes ensure these bearings maintain consistent performance characteristics while utilizing cost-effective materials such as carbon steel, stainless steel, or specialized alloys. The manufacturing process employs automated production systems that reduce labor costs and enhance consistency across large production volumes. Quality control measures ensure each low price bearing meets industry standards for dimensional accuracy, surface finish, and operational tolerance levels. These bearings feature standardized designs that facilitate easy installation and replacement procedures. Applications for low price bearings span numerous industries including automotive manufacturing, agricultural equipment, construction machinery, household appliances, and industrial automation systems. In automotive applications, these bearings support wheel assemblies, transmission components, and engine accessories where cost efficiency remains paramount. Agricultural equipment manufacturers integrate low price bearings into harvesting machines, irrigation systems, and livestock handling equipment. Construction machinery utilizes these bearings in conveyor systems, mixing equipment, and material handling devices. Household appliances such as washing machines, dryers, and kitchen equipment rely on low price bearings for smooth operation and extended service life. The versatility of low price bearings makes them suitable for both heavy-duty industrial applications and precision consumer products, demonstrating their adaptability across different operational environments and performance requirements.