Revolutionary Sealing Technology for Contamination Protection

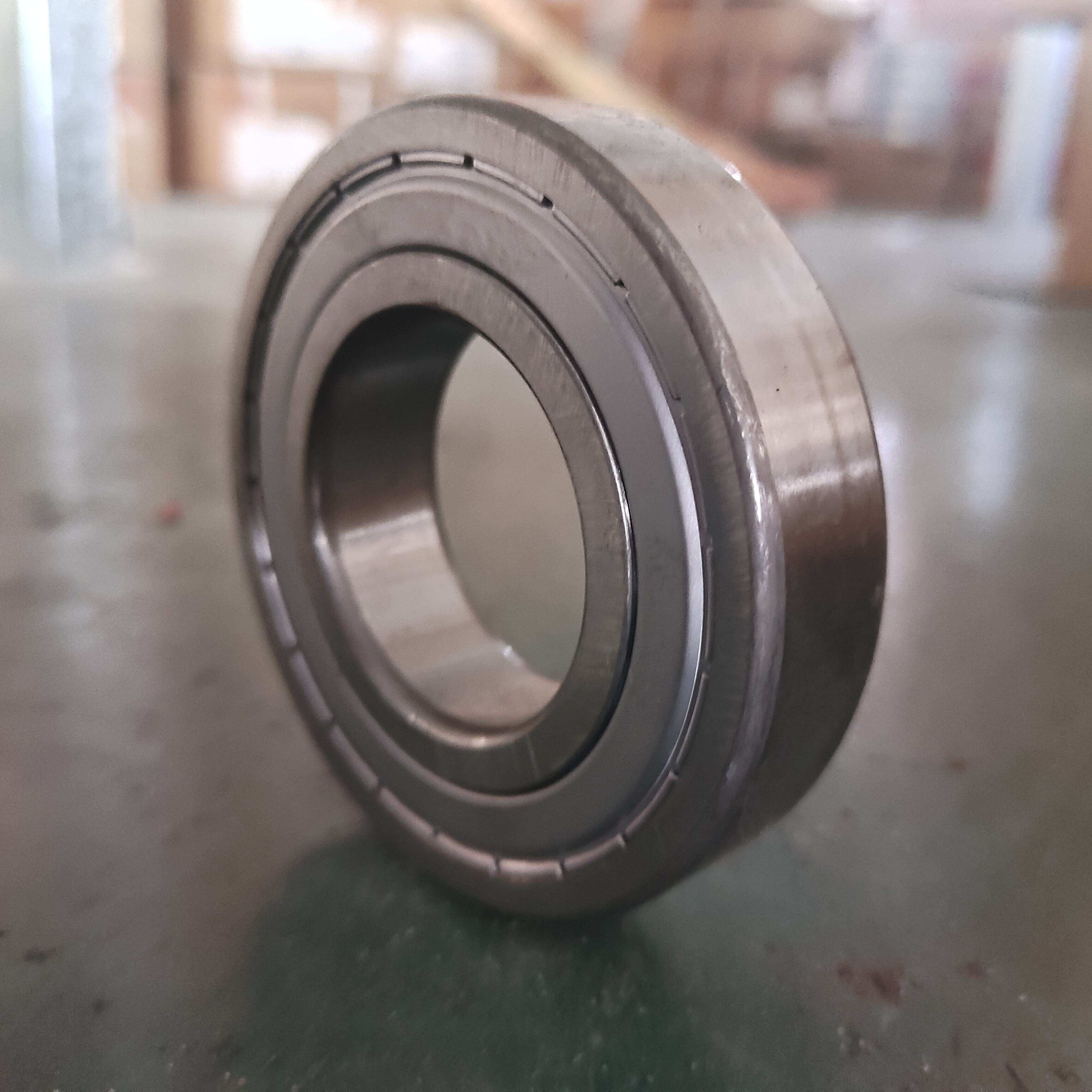

Breakthrough sealing innovations represent a cornerstone advancement in durable bearing technology, providing unprecedented protection against environmental contamination while maintaining optimal lubrication retention throughout extended operational periods. Multi-stage sealing systems incorporate elastomeric compounds specifically formulated to resist degradation from chemical exposure, temperature extremes, and mechanical stress, ensuring long-term effectiveness in challenging industrial environments. The sophisticated seal geometry design creates multiple barrier levels that prevent ingress of particulate matter, moisture, and corrosive substances while allowing internal pressure equalization during thermal expansion cycles. This comprehensive protection mechanism directly translates into extended bearing life expectancy, as contamination represents the primary cause of premature failure in standard bearing applications. Users benefit from dramatically reduced maintenance requirements as sealed durable bearing units operate effectively without frequent regreasing or cleaning procedures, allowing focus on core operational activities rather than routine component servicing. The sealed design also enables operation in previously unsuitable environments, expanding application possibilities into dusty, wet, or chemically aggressive conditions where conventional bearings would fail rapidly. Manufacturing facilities processing abrasive materials, food production environments requiring sanitary conditions, and outdoor equipment exposed to weather elements all benefit significantly from advanced sealing capabilities. The retention of premium lubricants within the sealed chamber ensures consistent lubrication film thickness, maintaining optimal friction characteristics and heat dissipation properties throughout the operational lifecycle. Quality testing procedures validate seal effectiveness across temperature ranges and pressure differentials, providing documented performance parameters that enable confident application selection. The modular sealing design allows customization for specific environmental challenges, with options for enhanced chemical resistance, extreme temperature capability, or specialized food-grade formulations. Installation advantages include simplified mounting procedures as sealed units eliminate the need for external sealing compound application or complex housing modifications typically required with conventional bearing installations.