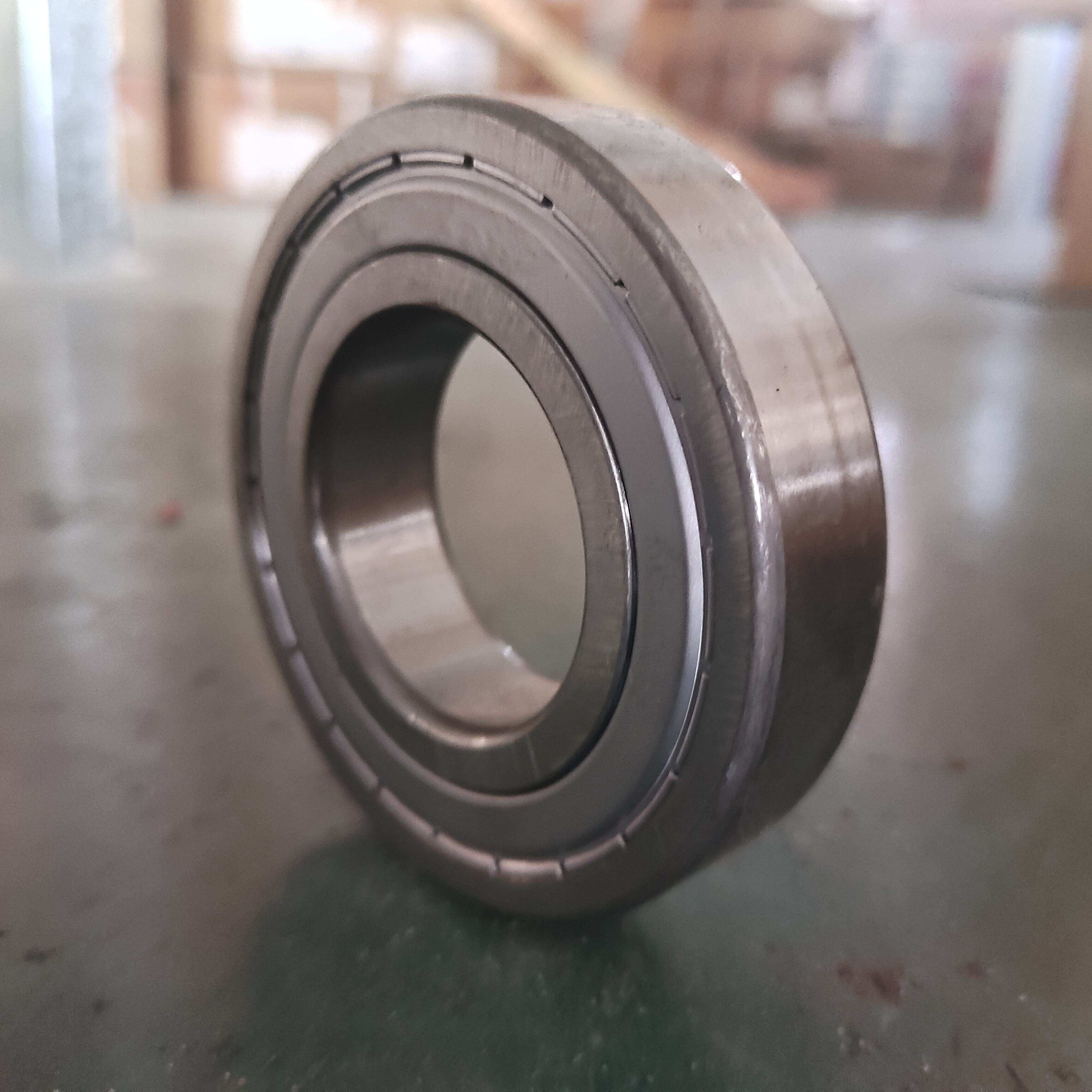

grofhandel draaigat

Groothandel-laaibloeie bied 'n omvattende oplossing vir besighede wat koste-effektiewe, hoë-kwaliteit laaibloeikomponente in groot hoeveelhede soek. Hierdie meganiese elemente tree op as noodsaaklike intermediêre verbindings tussen bewegende dele in masjinerie, en fasiliteer gladde rotasie terwyl wrywing verminder en verskeie belastings ondersteun word. Die groothandelsmark vir laaibloeie sluit uiteenlopende tipes in, insluitend kogellaaiers, rol-laaibloeie, druklaers en gespesialiseerde variante ontwerp vir spesifieke industriële toepassings. Moderne groothandelslaaibloeiprodukte bevat gevorderde materiale soos chroomstaal, roestvrye staal en keramiese samestellings wat die duursaamheid en prestasie verbeter in uitdagende bedryfsomgewings. Die tegnologiese verfyning van hedendaagse groothandelslaaibloeistelsels sluit presisie vervaardigingsprosesse in, waaronder rekenaarbeheerde masjinering en gehalteversekeringsprotokolle wat dimensionele akkuraatheid binne mikron-toleransies verseker. Hierdie komponente maak gebruik van gevorderde smeersisteme, beskermende seëls en geoptimaliseerde interne geometrieë wat bedryfsdoeltreffendheid maksimeer terwyl instandhoudingsvereistes tot die minimum beperk word. Toepassings vir groothandelslaaibloeiprodukte strek oor verskeie nywerhede, insluitend motorvervaardiging, lug- en ruimtevaartingenieurswese, industriële masjinerie, hernubare energiestelsels en swaar toerustingbedryf. Die veelsydigheid van groothandelslaaibloe-oplossings stel hulle in staat om in vervoersisteems, motoropstelle, pompe, kompressors en tellose ander meganiese toepassings ingebed te word waar rotasiebeweging plaasvind. Verspreidingsnetwerke vir groothandelslaaibloeiprodukte behels tipies gespesialiseerde leweransiers wat uitgebreide voorraad bly hou, tegniese ondersteuning bied en aangepaste oplossings aanbied wat afgestem is op spesifieke kliëntvereistes. Die globale groothandelslaaibloeimark bly uitbrei weens toenemende industriële outomatisering, infrastruktuurontwikkeling en tegnologiese vooruitgang oor vervaardigingssektore heen. Gehaltestandaarde vir groothandelslaaibloeiprodukte voldoen aan internasionale spesifikasies insluitend ISO-, ABEC- en DIN-klassifikasies wat konsekwente prestasie en uitruilbaarheid oor verskillende vervaardigers en toepassings waarborg.