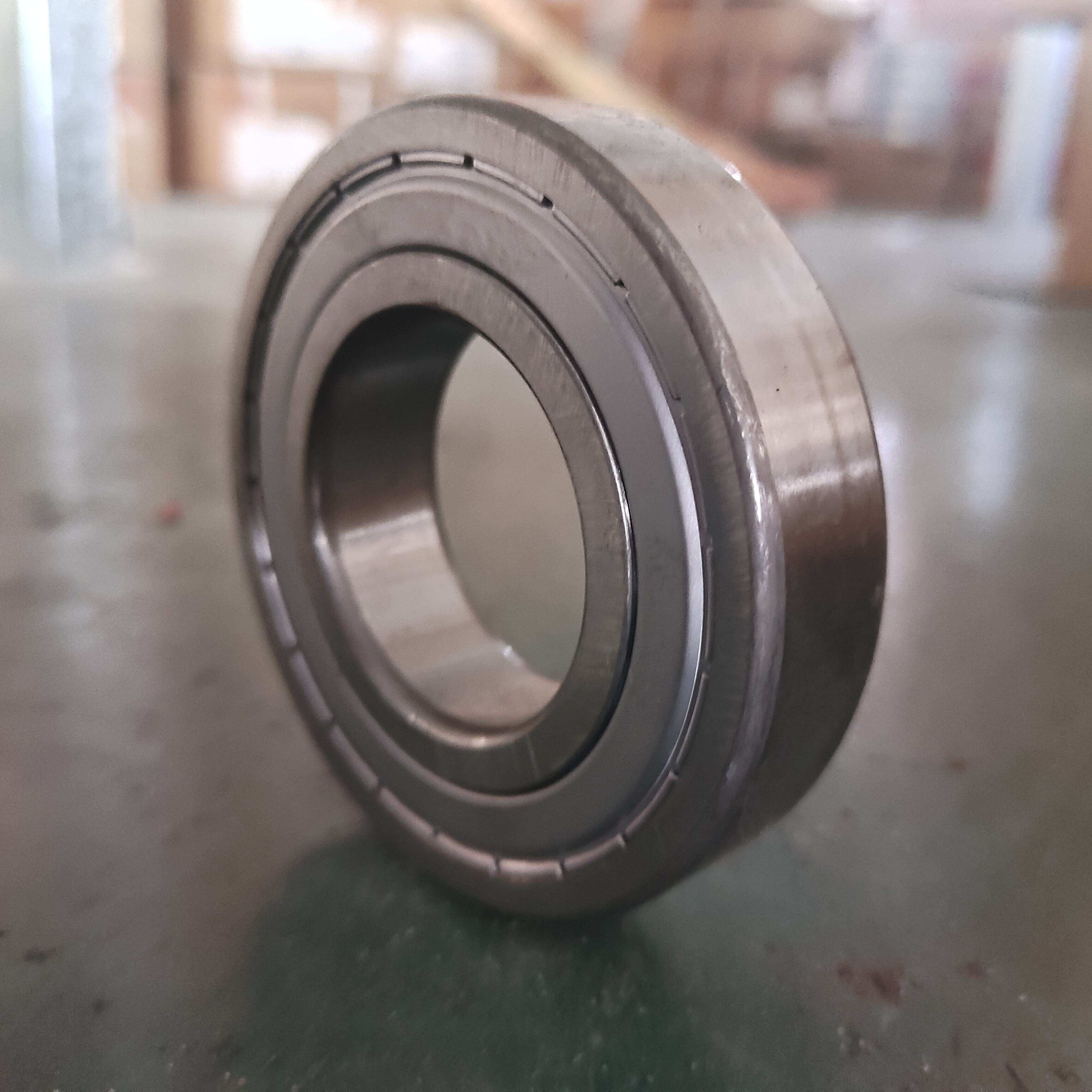

kwaliteit draaibare steunvas

Kwaliteitslagervet verteenwoordig 'n kritieke komponent in moderne meganiese stelsels, wat as die beskermende barrière tussen bewegende dele dien terwyl dit optimale prestasie en lewensduur verseker. Hierdie gespesialiseerde smeermiddel kombineer noukeurig gekose basisole met gevorderde verdikkingsmiddels en prestasietoevoegings om 'n superieure smeeroplossing te skep. Die primêre funksie van kwaliteitslagervet lê in die vermindering van wrywing tussen roterende elemente, die voorkoming van metaal-tot-metaal-kontak, en die dissiperen van hitte wat tydens bedryf gegenereer word. Kwaliteitslagervet behou sy konsekwentheid oor wisselende temperatuurbereik, wat betroubare beskerming bied in hoë-temperatuur industriële omgewings sowel as lae-temperatuur buite-toepassings. Die tegnologiese eienskappe van moderne lagervette sluit in verbeterde oksidasieweerstand, uitstekende waterweerstandvermoë, en uitstekende meganiese stabiliteit onder swaar lasse. Hierdie formuleringe bevat toonaangewende toevoegingspakke wat anti-slytasiebeskerming, korrosiewering en verlengde bedryfsintervalle lewer. Toepassings van kwaliteitslagervet strek oor verskeie nywerhede, vanaf motorfietswiele en elektriese motore tot swaar industriële masjinerie en presisie vervaardigingsapparatuur. Die veerkragtigheid van hierdie smeermiddele maak hulle geskik vir seël-vir-lewe-lagers in verbruikersapparate sowel as hoë-spoed-spindeltoepassings in masjienwerktuie. Vervaardigingsfasiliteite staatmaak op kwaliteitslagervet om produksiedoeltreffendheid te handhaaf terwyl instandhoudingskoste en toestelonderbrekings tot 'n minimum beperk word. Die strategiese keuse van gepaste lagerlubriking het 'n direkte impak op bedryfsbetroubaarheid, energiedoeltreffendheid en algehele toesteldoeltreffendheid. Moderne kwaliteitslagervetformulerings spreek spesifieke uitdagings aan soos ekstreme drukomstandighede, weerstand teen besmetting, en verenigbaarheid met verskillende seal-materiale. Hierdie gevorderde eienskappe verseker bestendige prestasie gedurende die beoogde bedryfslewe terwyl dit beskerming bied teen vroegtydige lagermislukking en kostelike herstelwerk.