uusimman suunnitelman vieruskorit

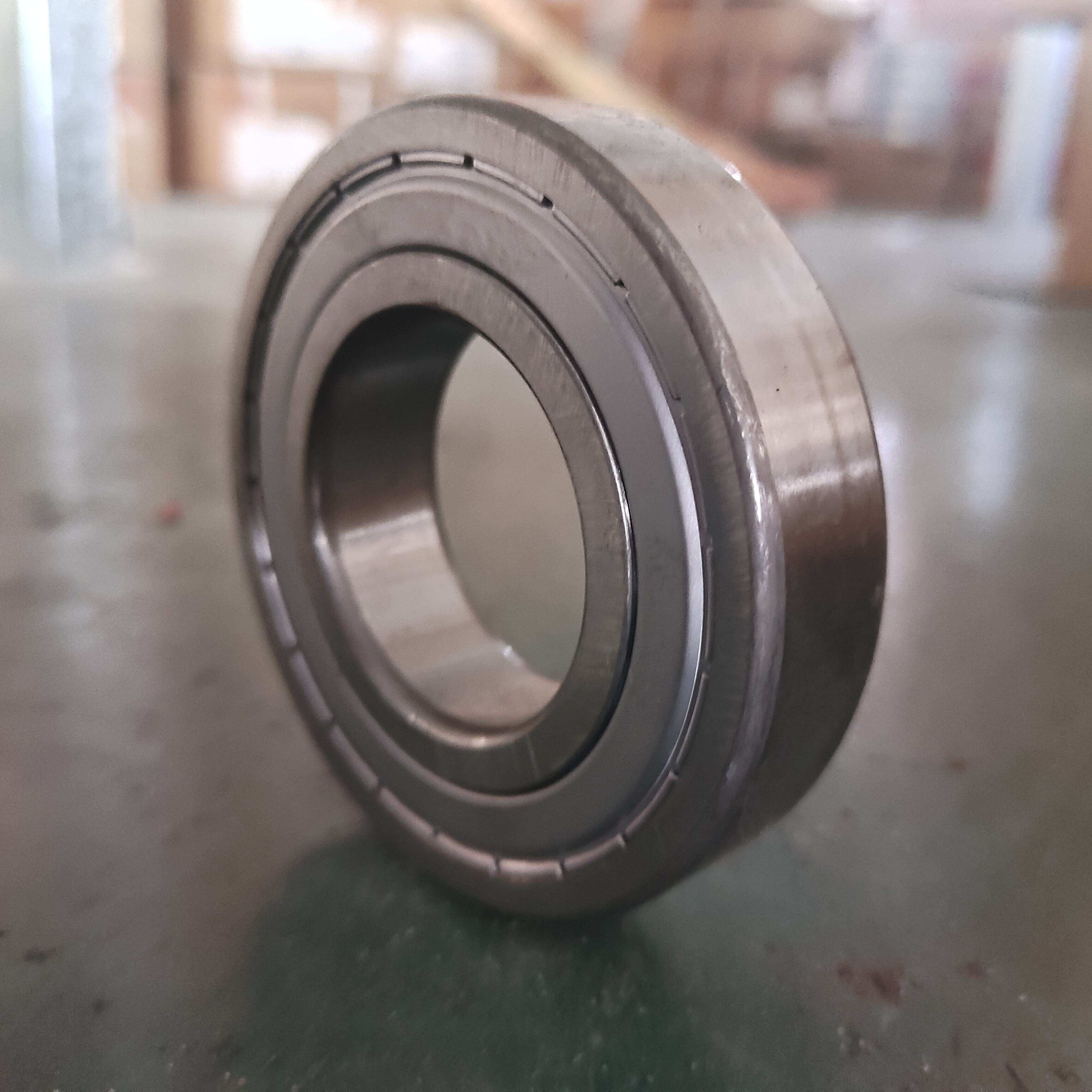

Uusimman suunnittelun vierintälaakerit edustavat vallankumouksellista edistystä koneenrakennuksessa, ja ne yhdistävät huippuluokan materiaaliteknologian ja tarkkuuden valmistustekniikat tarjotakseen erinomaista suorituskykyä monenlaisissa teollisissa sovelluksissa. Nämä modernit laakeriratkaisut sisältävät parannetun kuormituskapasiteetin, paremman kestävyyden ja optimoidun tehokkuuden, jotka huomattavasti ylittävät perinteiset laakeriratkaisut. Uusimman suunnittelun vierintälaakerit käyttävät edistyneitä terästyyppejä, keramiikkahybridielementtejä ja erikoiskäsittelyjä pinnalle, mikä mahdollistaa sulavamman toiminnan ja pidemmän käyttöiän. Näissä laakereissa on innovatiivisia koppirakenteita, jotka on valmistettu korkean suorituskyvyn polymeereistä tai kevytmetalleista, ja ne vähentävät kitkaa ja kulutusta käytön aikana. Uusimman suunnittelun vierintälaakereiden tiivistysjärjestelmissä käytetään edistyneitä elastomeeriyhdisteitä ja labyrinttitiiviystä, jotka tarjoavat poikkeuksellisen suojauksen saasteilta samalla kun säilyttävät optimaalisen voitelun. Tarkkuusvalmistustekniikat varmistavat johdonmukaisen mitan ja pinnanlaadun, jolloin nämä laakerit voivat toimia tehokkaasti ääriolosuhteissa, kuten korkeissa lämpötiloissa, raskaiden kuormien alla ja syövyttävissä ympäristöissä. Uusimman suunnittelun vierintälaakerit sisältävät optimoidun sisäisen geometrian, joka jakaa rasituksen tasaisemmin kantaville pinnoille, vähentää väsymistä ja pidentää käyttöikää. Nämä laakerit ottavat tehokkaasti vastaan sekä säteittäisiä että aksiaalisia kuormia, mikä tekee niistä sopivia monimutkaisiin koneisiin. Edistyneitä voiteluteknologioita, mukaan lukien kiinteitä voiteluaineita ja erikoisvoiteita, on integroitu uusimman suunnittelun vierintälaakereihin vähentämään huoltovaatimuksia ja parantamaan suorituskyvyn johdonmukaisuutta. Valmistusprosessiin kuuluu tietokoneavusteinen suunnitteluoptimointi ja edistyneet laadunvalvontajärjestelmät, jotka varmistavat, että jokainen laakeri täyttää tiukat suorituskyvyn vaatimukset. Nämä innovaatiot tekevät uusimman suunnittelun vierintälaakereista olennaisia komponentteja nykyaikaisessa koneistossa automaatio-, avaruus-, teollisuuslaitteisto- ja uusiutuvan energian aloilla, joissa luotettavuus ja suorituskyky ovat keskeisiä menestystekijöitä.