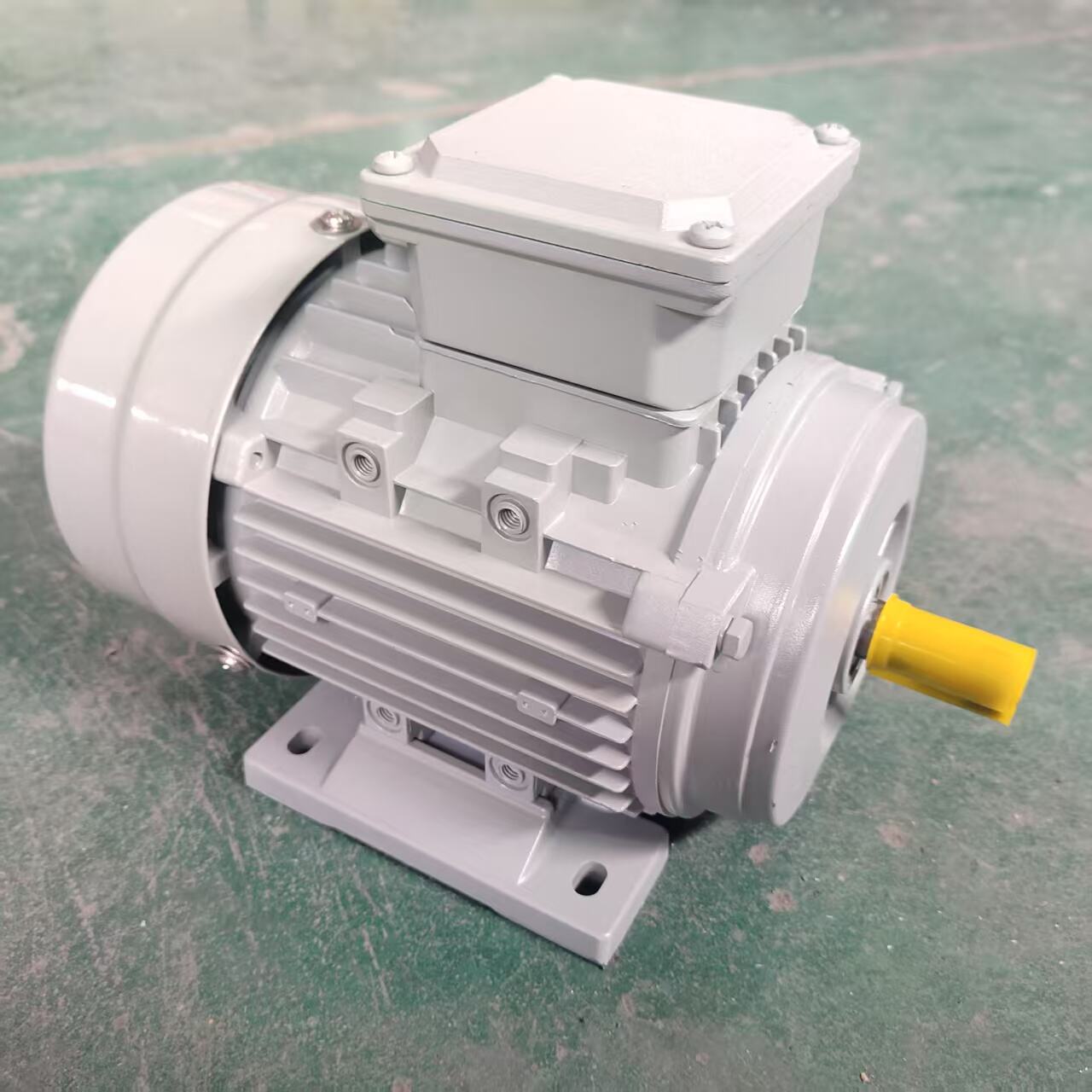

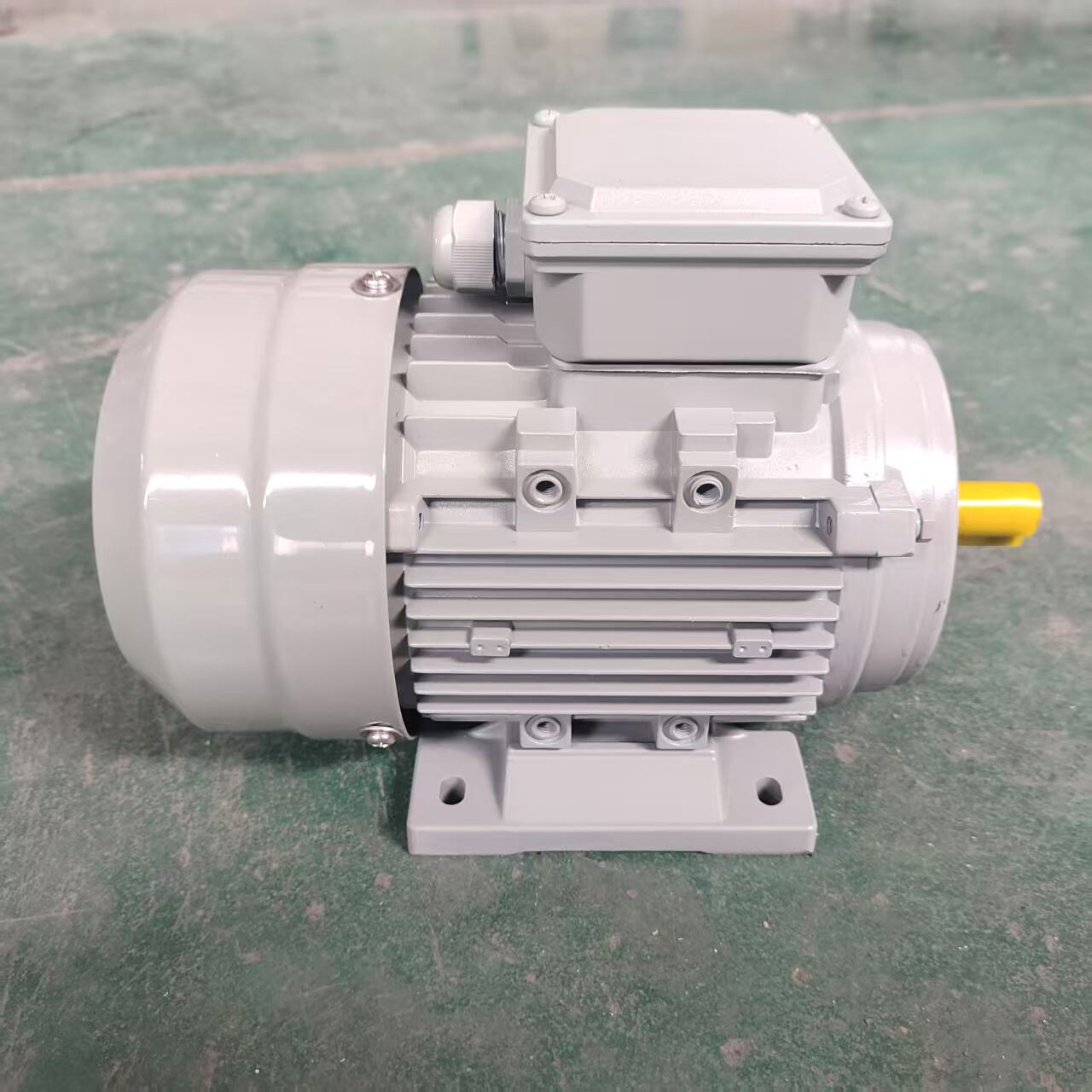

Precise Control and Operational Reliability

The safe synchronous motor provides exceptional precise control and operational reliability that makes it indispensable for applications requiring exact positioning, consistent speed, and dependable performance over extended periods. This precision control capability stems from the motor's synchronous operation characteristics, which maintain perfect synchronization between the rotor and stator magnetic fields regardless of load variations or external disturbances. Unlike asynchronous motors that experience speed variations under changing load conditions, the safe synchronous motor maintains constant rotational velocity with accuracy exceeding ninety-nine percent, ensuring consistent output quality and production efficiency. Advanced digital control systems enable precise torque regulation and speed adjustment, allowing operators to optimize motor performance for specific applications and operating conditions. The motor responds instantly to control signals, providing rapid acceleration and deceleration capabilities that enhance system responsiveness and productivity. Position control accuracy reaches levels suitable for high-precision manufacturing processes, robotics applications, and automated systems where exact positioning is critical for product quality and operational success. The motor's control interface integrates seamlessly with industrial automation systems, programmable logic controllers, and supervisory control systems, enabling centralized monitoring and control of multiple motors within complex manufacturing environments. Operational reliability is ensured through robust construction using premium materials and advanced manufacturing techniques that withstand harsh industrial conditions including temperature extremes, vibration, moisture, and contaminants. The motor's bearing systems are designed for extended service life with minimal maintenance requirements, while sealed enclosures protect internal components from environmental hazards. Predictive maintenance capabilities monitor component wear and performance degradation, alerting operators to potential issues before they affect production or cause unexpected failures. The motor's modular design facilitates quick component replacement and repair, minimizing downtime and maintenance costs while ensuring continued reliable operation. Comprehensive testing and quality assurance procedures verify motor performance and reliability before delivery, providing customers with confidence in their investment and ensuring consistent operation throughout the motor's service life.