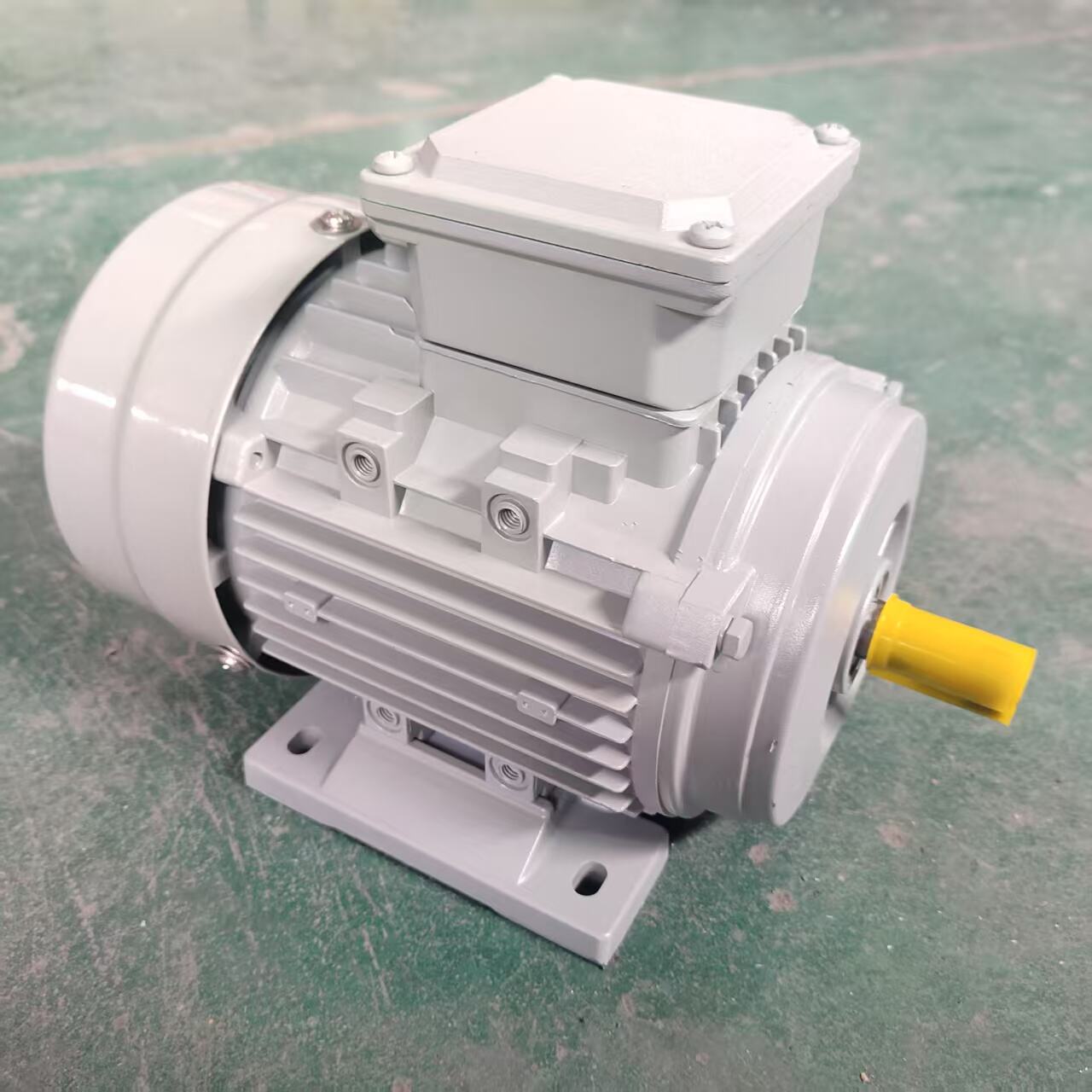

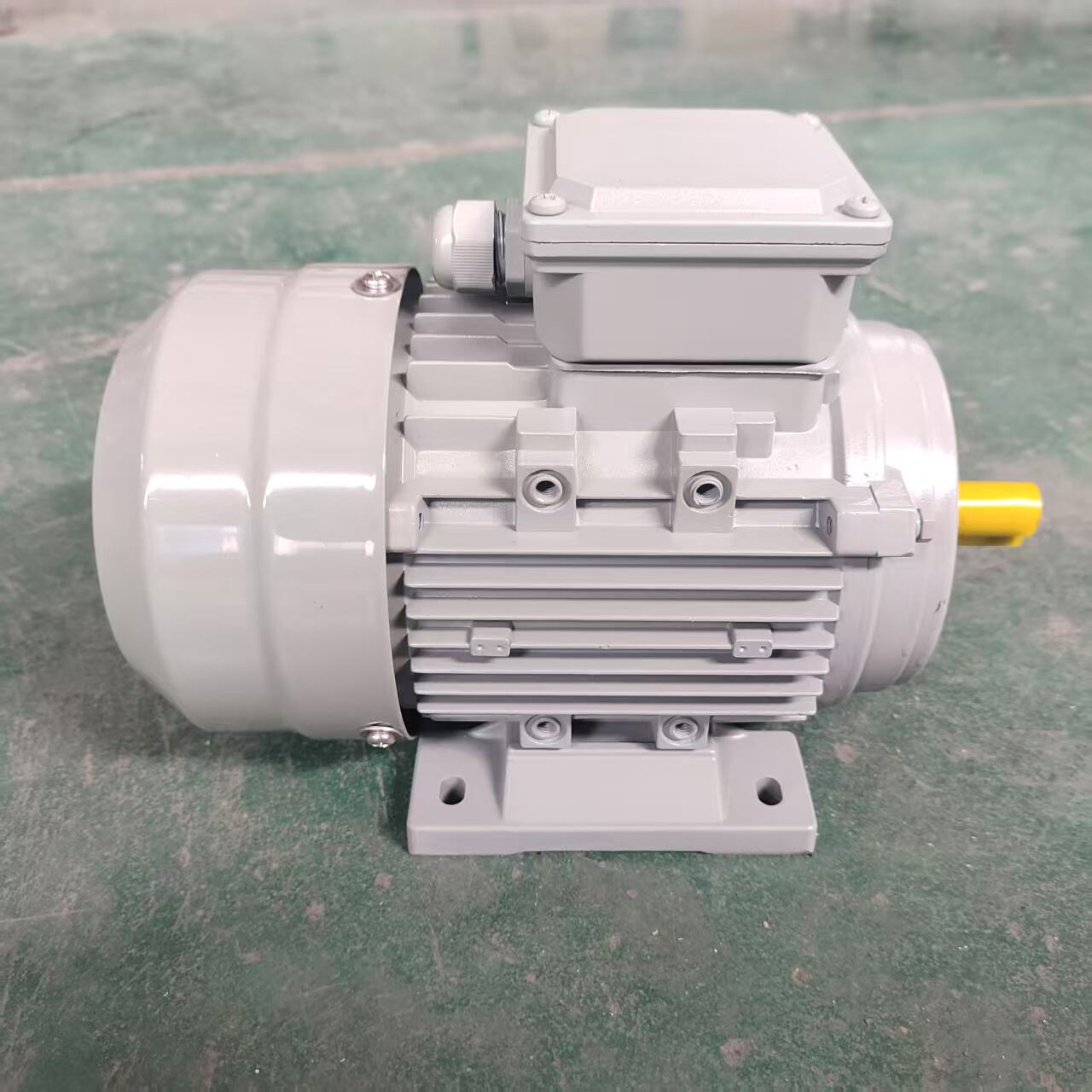

Ακριβής Έλεγχος και Λειτουργική Αξιοπιστία

Ο ασφαλής σύγχρονος κινητήρας παρέχει εξαιρετικό ακριβή έλεγχο και λειτουργική αξιοπιστία, κάνοντάς τον αναπόσπαστο για εφαρμογές που απαιτούν ακριβή τοποθέτηση, σταθερή ταχύτητα και αξιόπιστη απόδοση για μεγάλο χρονικό διάστημα. Αυτή η δυνατότητα ακριβούς ελέγχου προέρχεται από τα χαρακτηριστικά σύγχρονης λειτουργίας του κινητήρα, ο οποίος διατηρεί τέλεια συγχρονισμό μεταξύ των μαγνητικών πεδίων του δρομέα και του στάτη, ανεξάρτητα από μεταβολές φορτίου ή εξωτερικές διαταραχές. Σε αντίθεση με τους ασύγχρονους κινητήρες, οι οποίοι υφίστανται μεταβολές ταχύτητας υπό μεταβαλλόμενες συνθήκες φορτίου, ο ασφαλής σύγχρονος κινητήρας διατηρεί σταθερή περιστροφική ταχύτητα με ακρίβεια που υπερβαίνει το 99%, εξασφαλίζοντας σταθερή ποιότητα παραγωγής και αποδοτικότητα. Προηγμένα ψηφιακά συστήματα ελέγχου επιτρέπουν ακριβή ρύθμιση ροπής και προσαρμογή ταχύτητας, επιτρέποντας στους χειριστές να βελτιστοποιήσουν την απόδοση του κινητήρα για συγκεκριμένες εφαρμογές και συνθήκες λειτουργίας. Ο κινητήρας ανταποκρίνεται αμέσως σε σήματα ελέγχου, παρέχοντας γρήγορες δυνατότητες επιτάχυνσης και επιβράδυνσης που αυξάνουν την ανταπόκριση και την παραγωγικότητα του συστήματος. Η ακρίβεια ελέγχου θέσης φτάνει επίπεδα κατάλληλα για διεργασίες υψηλής ακρίβειας στην κατασκευή, εφαρμογές ρομποτικής και αυτοματοποιημένα συστήματα, όπου η ακριβής τοποθέτηση είναι κρίσιμη για την ποιότητα του προϊόντος και τη λειτουργική επιτυχία. Η διεπαφή ελέγχου του κινητήρα ενσωματώνεται ομαλά με συστήματα βιομηχανικού αυτοματισμού, προγραμματιζόμενους λογικούς ελεγκτές και συστήματα εποπτείας, επιτρέποντας κεντρική παρακολούθηση και έλεγχο πολλών κινητήρων σε περίπλοκα περιβάλλοντα παραγωγής. Η λειτουργική αξιοπιστία εξασφαλίζεται μέσω ανθεκτικής κατασκευής με χρήση υψηλής ποιότητας υλικών και προηγμένων τεχνικών κατασκευής, οι οποίες αντέχουν σε σκληρές βιομηχανικές συνθήκες, συμπεριλαμβανομένων ακραίων θερμοκρασιών, κραδασμών, υγρασίας και ρύπων. Τα συστήματα των ρουλεμάν του κινητήρα έχουν σχεδιαστεί για επεκτατό χρόνο ζωής με ελάχιστες απαιτήσεις συντήρησης, ενώ σφραγισμένα περιβλήματα προστατεύουν τα εσωτερικά εξαρτήματα από περιβαλλοντικούς κινδύνους. Δυνατότητες προληπτικής συντήρησης παρακολουθούν τη φθορά των εξαρτημάτων και την υποβάθμιση της απόδοσης, ειδοποιώντας τους χειριστές για πιθανά προβλήματα πριν επηρεάσουν την παραγωγή ή προκαλέσουν απρόβλεπτες βλάβες. Ο μοντουλωτός σχεδιασμός του κινητήρα διευκολύνει τη γρήγορη αντικατάσταση και επισκευή εξαρτημάτων, ελαχιστοποιώντας τον χρόνο αδράνειας και τα κόστη συντήρησης, ενώ εξασφαλίζει συνεχή αξιόπιστη λειτουργία. Εκτεταμένες δοκιμές και διαδικασίες εξασφάλισης ποιότητας επαληθεύουν την απόδοση και την αξιοπιστία του κινητήρα πριν την παράδοση, παρέχοντας στους πελάτες εμπιστοσύνη στην επένδυσή τους και διασφαλίζοντας σταθερή λειτουργία καθ' όλη τη διάρκεια της ζωής του κινητήρα.