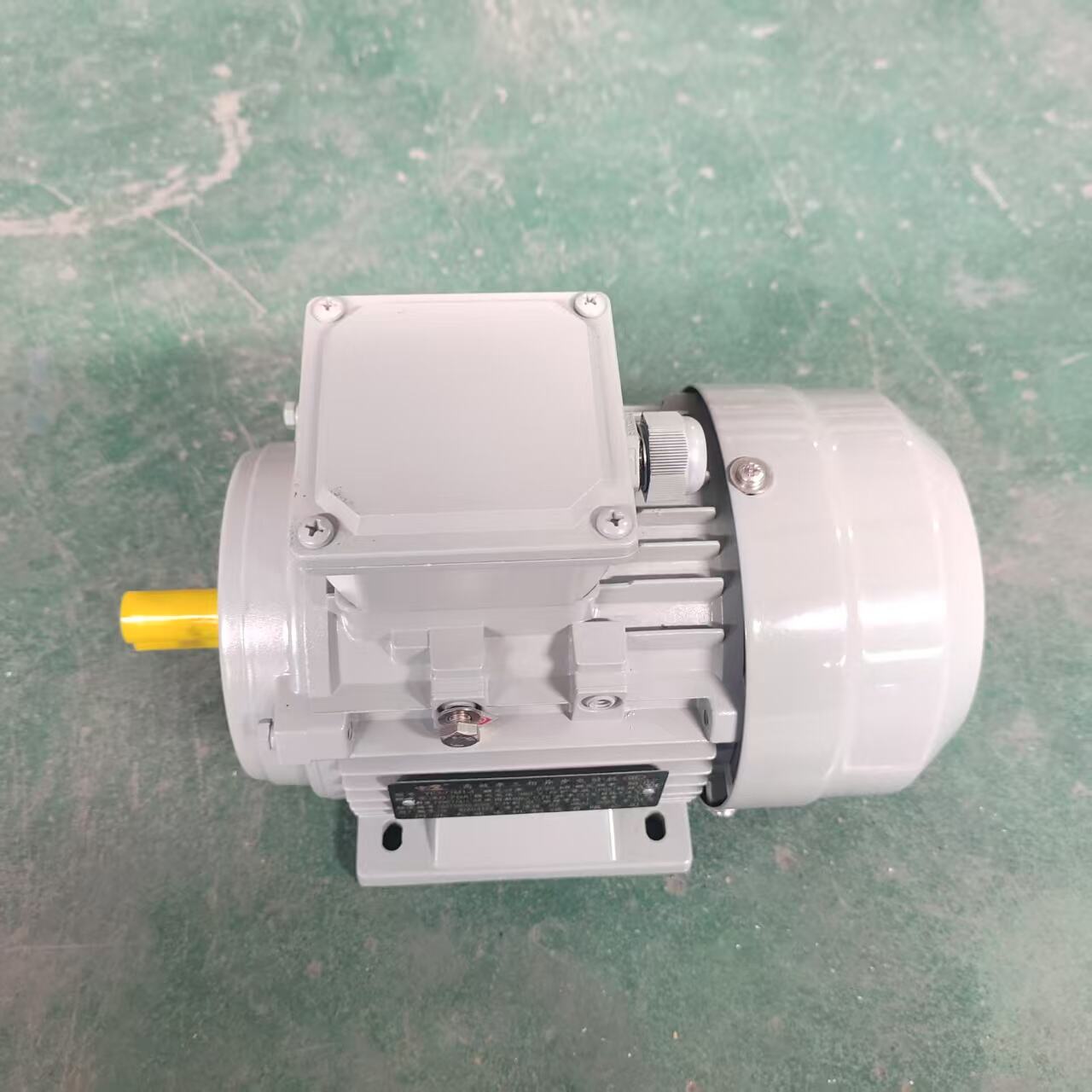

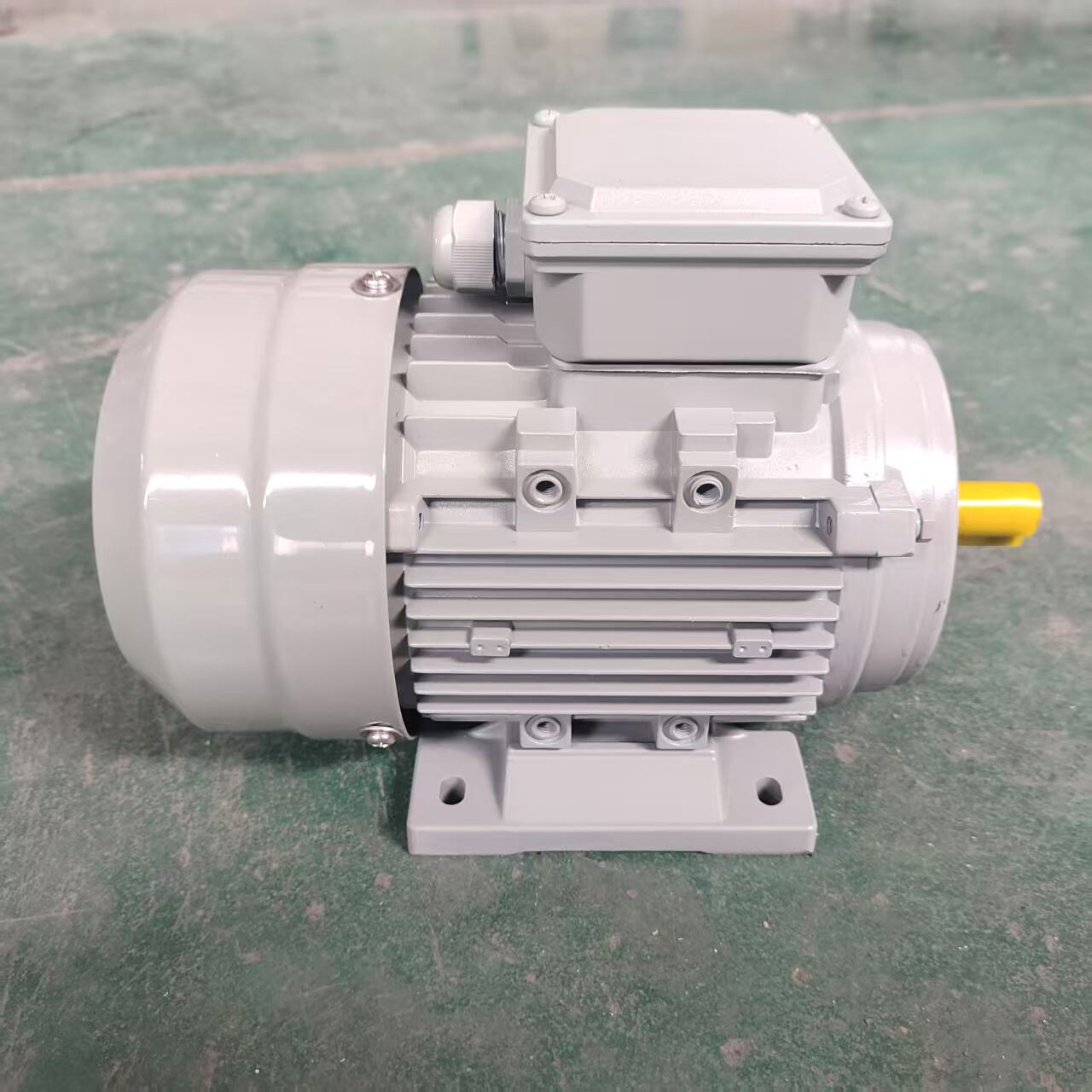

china synchronous motor

The china synchronous motor represents a pinnacle of precision engineering in industrial drive technology, delivering exceptional performance through its unique operational characteristics. This advanced motor type operates at a constant speed that remains synchronized with the supply frequency, regardless of load variations within its rated capacity. Unlike asynchronous motors, the china synchronous motor maintains perfect speed regulation, making it indispensable for applications requiring precise timing and coordination. The motor features a rotor that rotates at exactly the same speed as the rotating magnetic field produced by the stator windings, achieved through either permanent magnets or electromagnets in the rotor construction. This synchronization capability enables the china synchronous motor to provide superior efficiency levels, often exceeding 95% in optimal operating conditions. The technological foundation includes advanced magnetic materials, precision-wound stator coils, and sophisticated control systems that ensure reliable operation across diverse industrial environments. Key functions encompass power factor correction, where the china synchronous motor can operate at leading, lagging, or unity power factors, effectively improving overall system efficiency. The motor excels in applications requiring constant speed operation, such as conveyor systems, pumps, compressors, and manufacturing equipment where timing precision is critical. Advanced features include variable excitation control, which allows operators to adjust the motor's reactive power contribution to the electrical system. The china synchronous motor incorporates robust construction materials and advanced cooling systems to ensure longevity in demanding industrial applications. Modern variants feature digital control interfaces, remote monitoring capabilities, and integration with industrial automation systems. These motors demonstrate exceptional starting characteristics when equipped with appropriate starting mechanisms, overcoming the traditional limitation of synchronous motor technology. The combination of high efficiency, precise speed control, and power factor correction capabilities positions the china synchronous motor as an optimal choice for energy-conscious industrial operations seeking reliable, long-term performance solutions.