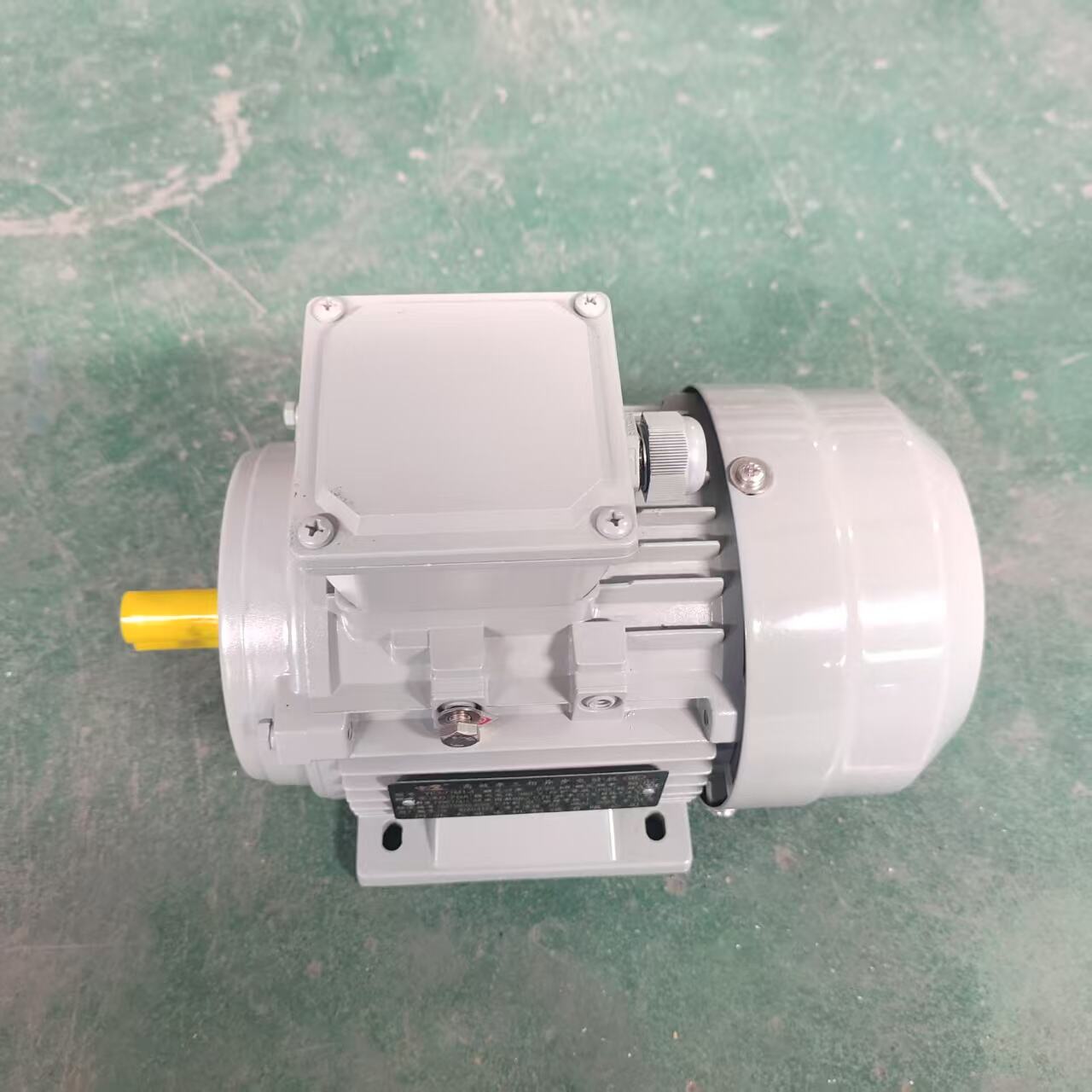

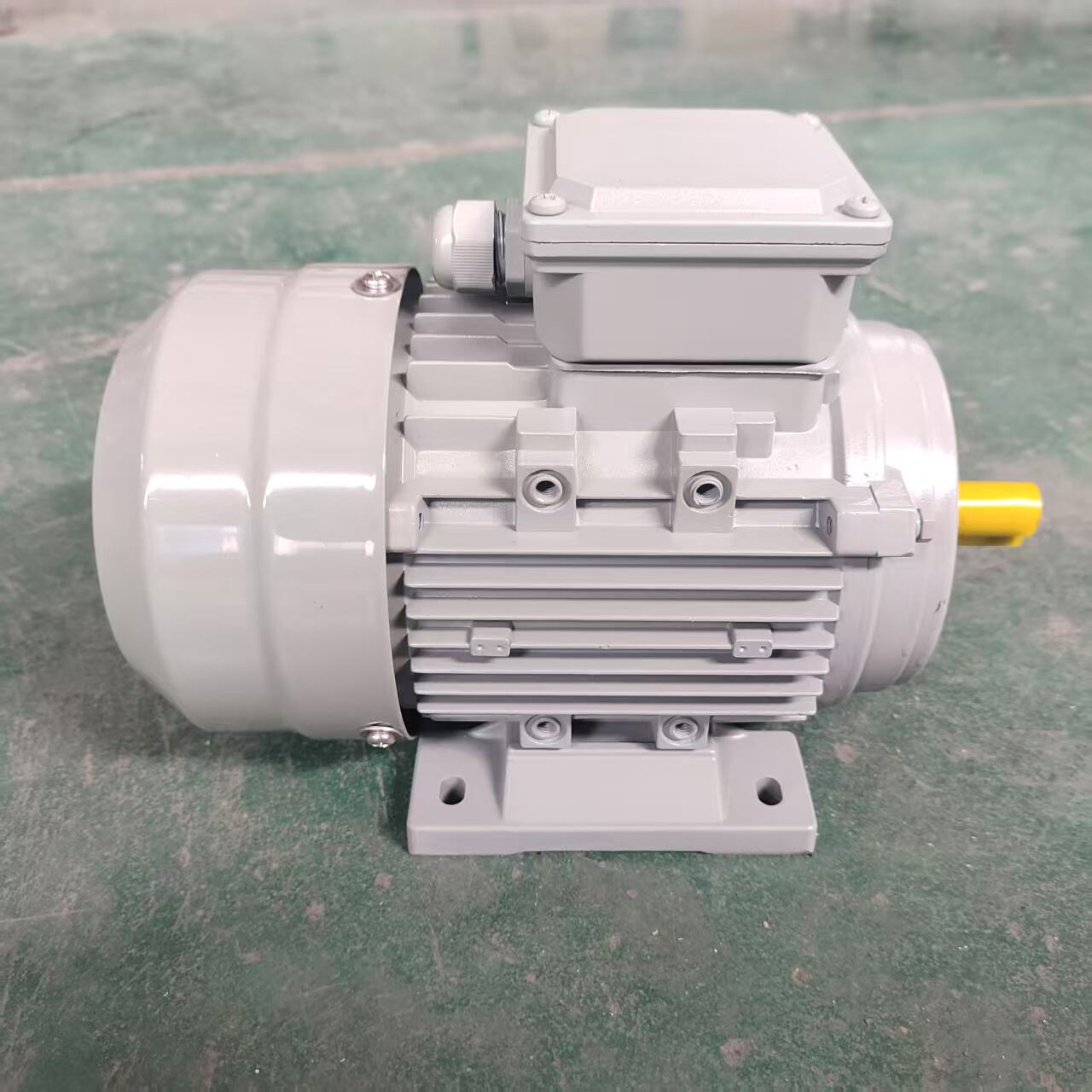

kiinalainen synkronimoottori

Kiinalainen synkronimoottori edustaa tarkkuuuden huippua teollisessa ainetekniikassa, tarjoten erinomaista suorituskykyä ainutlaatuisen toiminnan kautta. Tämä edistynyt moottorityyppi toimii vakionopeudella, joka pysyy synkronissa syöttötaajuuden kanssa riippumatta kuormituksesta sen nimelliskapasiteetin sisällä. Epäsynkronimoottoreiden tapaan kiinalainen synkronimoottori säilyttää täydellisen nopeudensäädön, mikä tekee siitä välttämättömän sovelluksissa, joissa vaaditaan tarkkaa ajoitusta ja koordinaatiota. Moottorissa on roottori, joka pyörii täsmälleen samalla nopeudella kuin staattorikäämien tuottama pyörivä magneettikenttä, saavutettuna joko roottorin rakenteessa olevien pysyvien magneettien tai sähkömagneettien avulla. Tämä synkronointikyky mahdollistaa kiinalaisen synkronimoottorin tarjota ylivoimaisia hyötysuhteita, jotka usein ylittävät 95 % optimaalisissa käyttöolosuhteissa. Tekninen perusta sisältää edistyneitä magneettimateriaaleja, tarkasti kierrettyjä staattorikeloja ja kehittyneitä ohjausjärjestelmiä, jotka takaavat luotettavan toiminnan monenlaisissa teollisissa ympäristöissä. Keskeisiin toimintoihin kuuluu tehokerroin-korjaus, jossa kiinalainen synkronimoottori voi toimia etuvaiheessa, jälkivaiheessa tai yksikkötehokertoimella, parantaen näin tehokkaasti koko järjestelmän hyötysuhdetta. Moottori loistaa sovelluksissa, joissa vaaditaan vakionopeutta, kuten kuljettimet, pumput, puristimet ja valmistuslaitteet, joissa ajoituksen tarkkuus on kriittistä. Edistyneisiin ominaisuuksiin kuuluu muuttuva viritys-ohjaus, joka mahdollistaa käyttäjien säätää moottorin reaktiivitehon osuutta sähköverkossa. Kiinalainen synkronimoottori sisältää kestäviä rakennemateriaaleja ja edistyneitä jäähdytysjärjestelmiä varmistaakseen pitkän käyttöiän vaativissa teollisissa sovelluksissa. Nykyaikaiset versiot sisältävät digitaaliset ohjainliitännät, kaukokontrollin ja integraation teollisten automaatiojärjestelmien kanssa. Nämä moottorit osoittavat poikkeuksellisia käynnistysominaisuuksia, kun niissä on asianmukaiset käynnistysmekanismit, voittaen synkronimoottoritekniikan perinteisen rajoituksen. Korkean hyötysuhteen, tarkan nopeudensäädön ja tehokertoimen korjauskyvyn yhdistäminen asettaa kiinalaisen synkronimoottorin optimaaliseksi valinnaksi energiatehokkuutta arvostaville teollisille toiminnoille, jotka etsivät luotettavia, pitkäaikaisia suorituskykyratkaisuja.