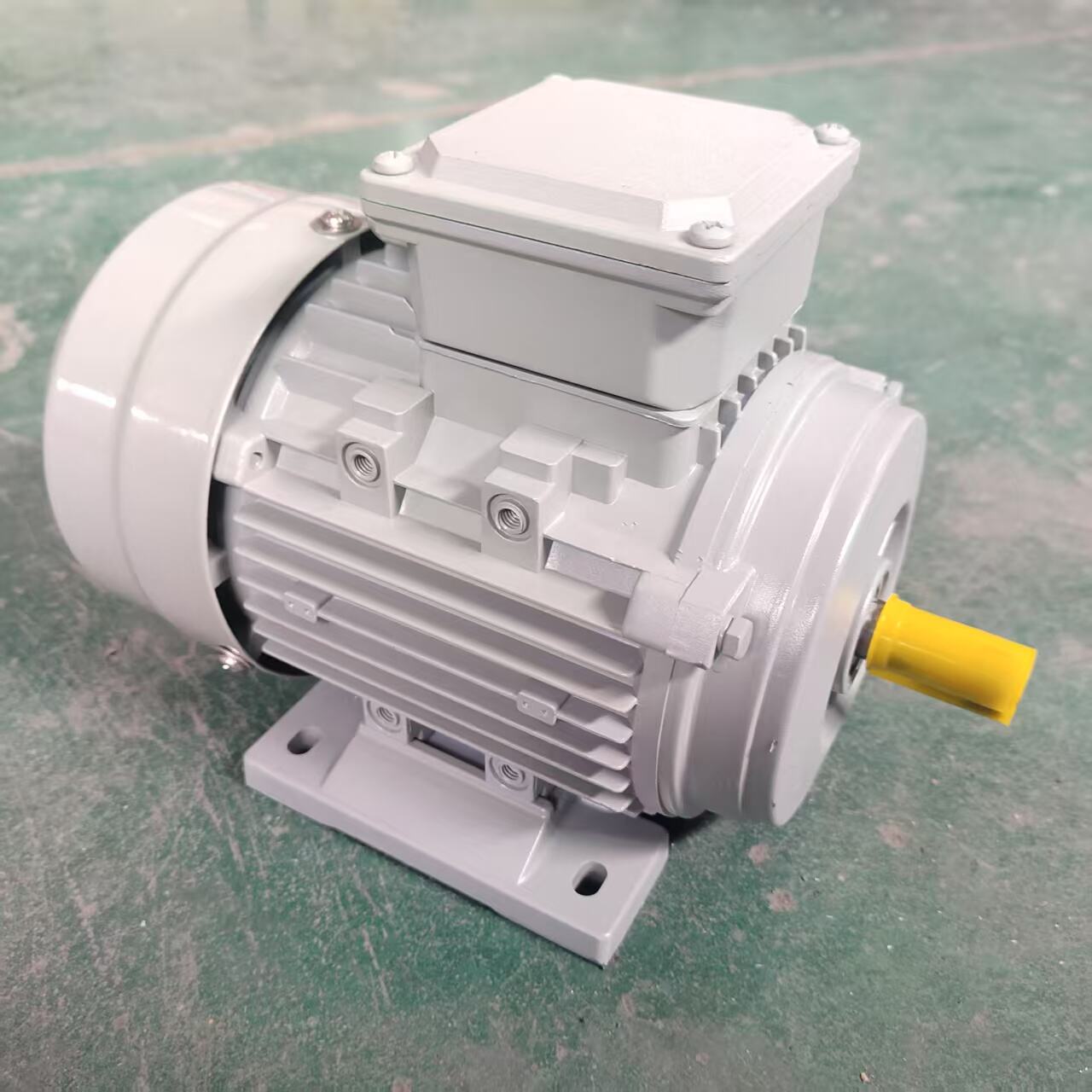

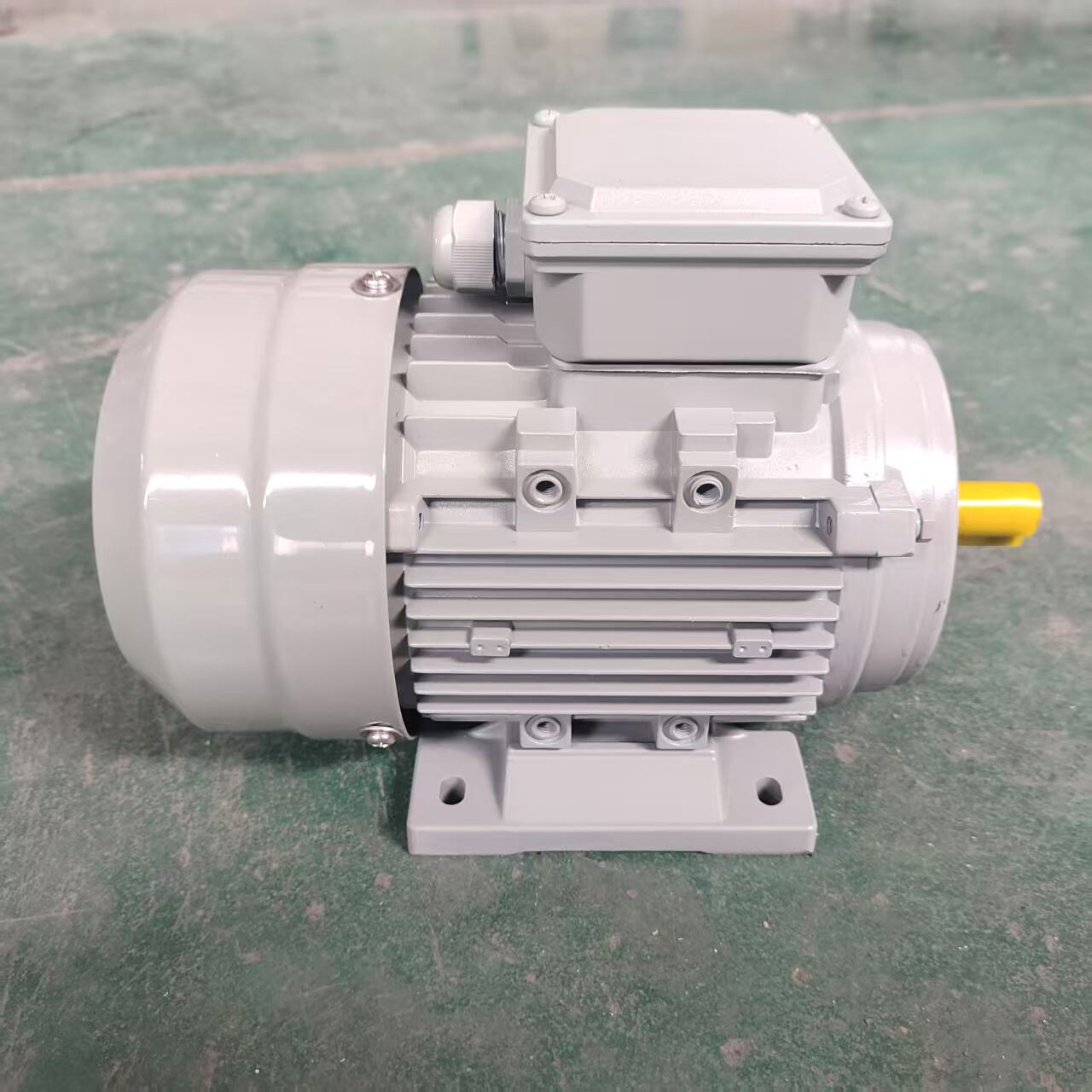

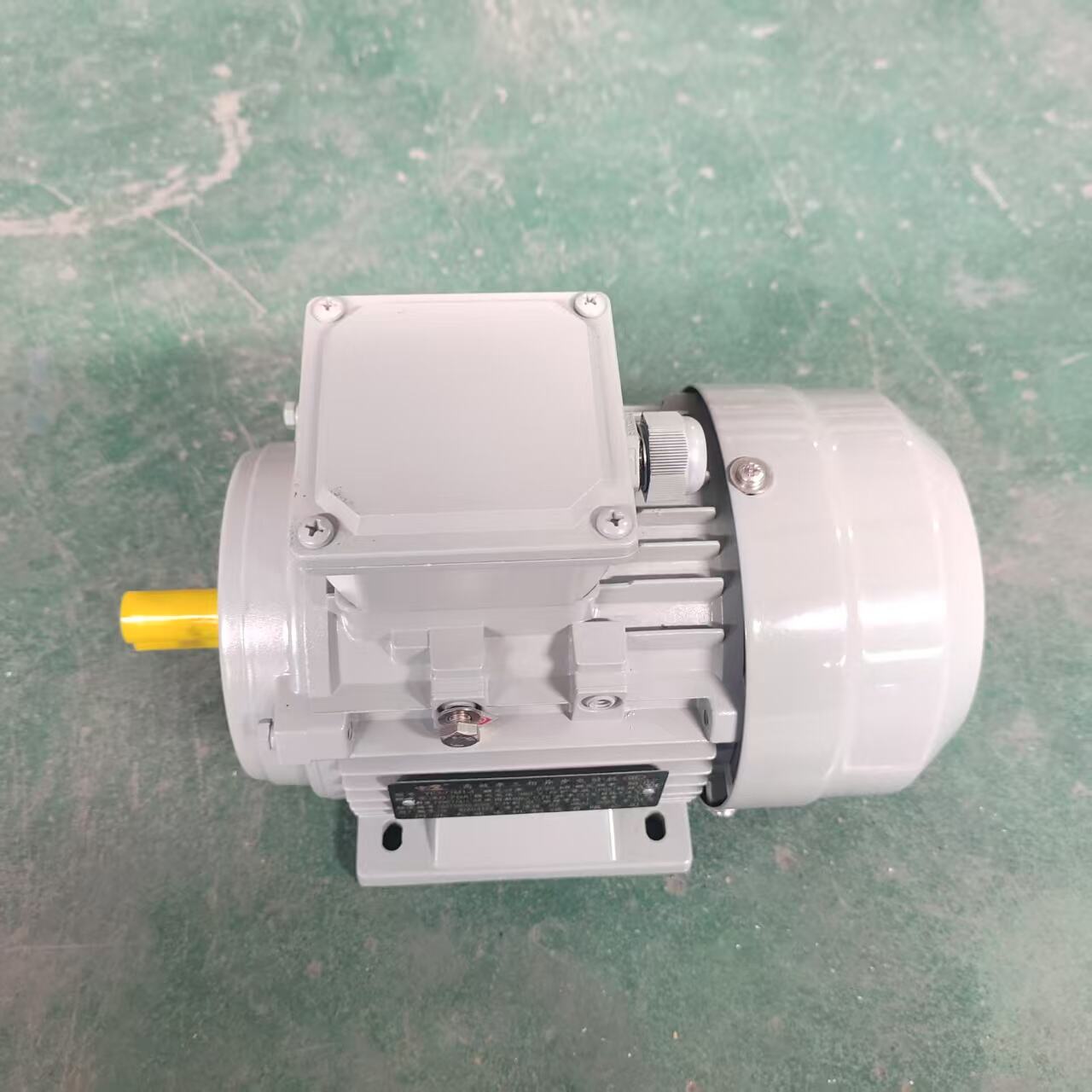

cheap synchronous motor

A cheap synchronous motor represents an excellent balance between performance and affordability in the electric motor industry. These motors operate at a constant speed that remains synchronized with the frequency of the alternating current supply, making them ideal for applications requiring precise speed control. Unlike asynchronous motors, cheap synchronous motors maintain their rotational speed regardless of load variations within their operating range. The fundamental principle behind these motors involves the interaction between a rotating magnetic field produced by the stator windings and a magnetic field generated by the rotor. This synchronization ensures consistent performance across various operating conditions. Modern cheap synchronous motors incorporate advanced materials and manufacturing techniques that reduce production costs while maintaining reliability. The rotor typically contains permanent magnets or electromagnets that create the necessary magnetic field for synchronous operation. These motors feature excellent power factor characteristics, often operating at unity power factor or even leading power factor conditions. The technological features of cheap synchronous motors include robust construction, efficient heat dissipation systems, and optimized magnetic circuits. Many models incorporate brushless designs that eliminate maintenance requirements associated with traditional brush-type motors. The control systems for these motors have become increasingly sophisticated, offering precise speed regulation and torque control capabilities. Applications for cheap synchronous motors span numerous industries, including manufacturing automation, HVAC systems, conveyor systems, and precision machinery. In industrial settings, these motors drive pumps, compressors, and fans where constant speed operation is essential. The automotive industry utilizes cheap synchronous motors in electric vehicle applications, power steering systems, and various auxiliary components. Consumer appliances such as washing machines, dishwashers, and air conditioning units frequently employ these motors for their reliability and efficiency. The medical equipment sector relies on cheap synchronous motors for devices requiring precise positioning and quiet operation.