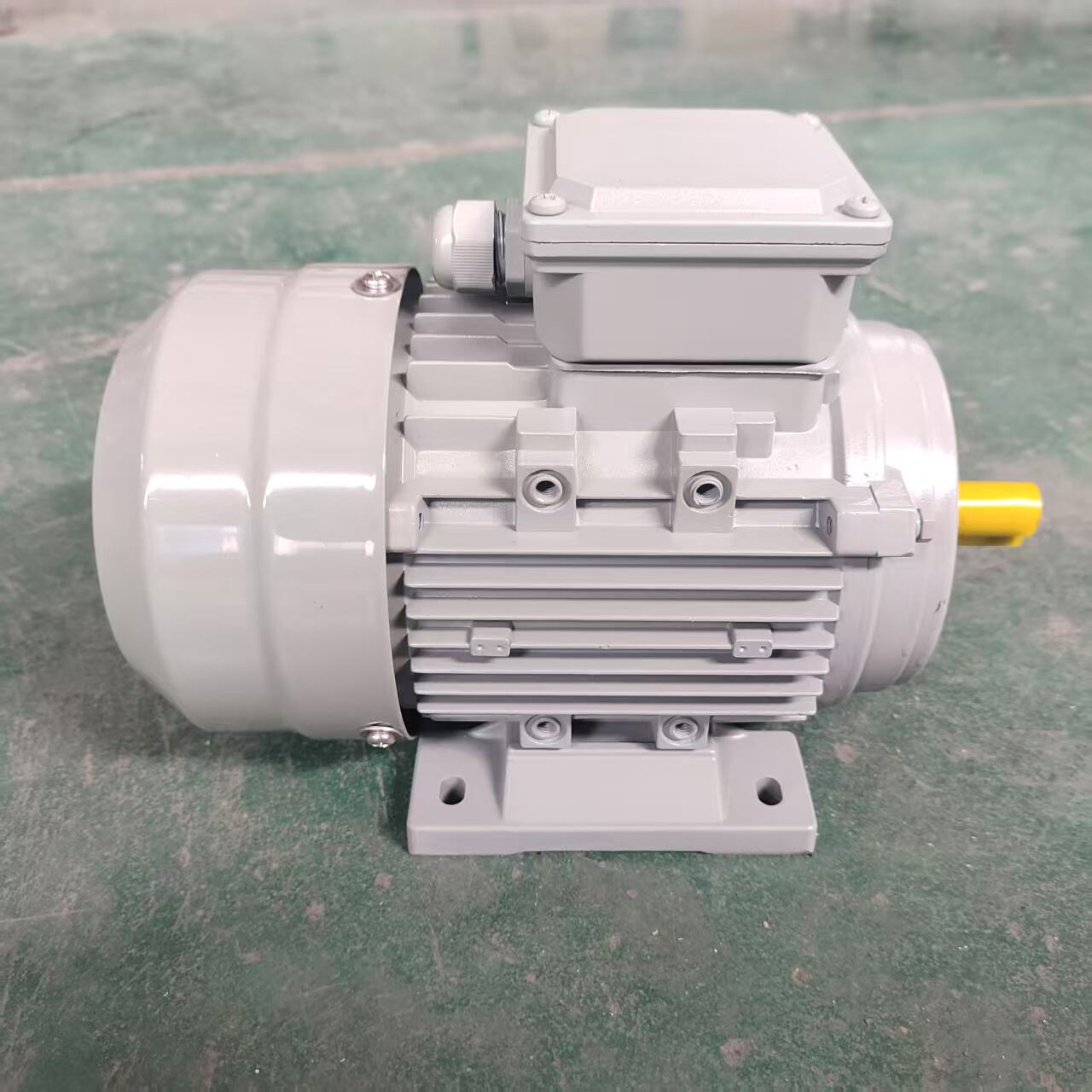

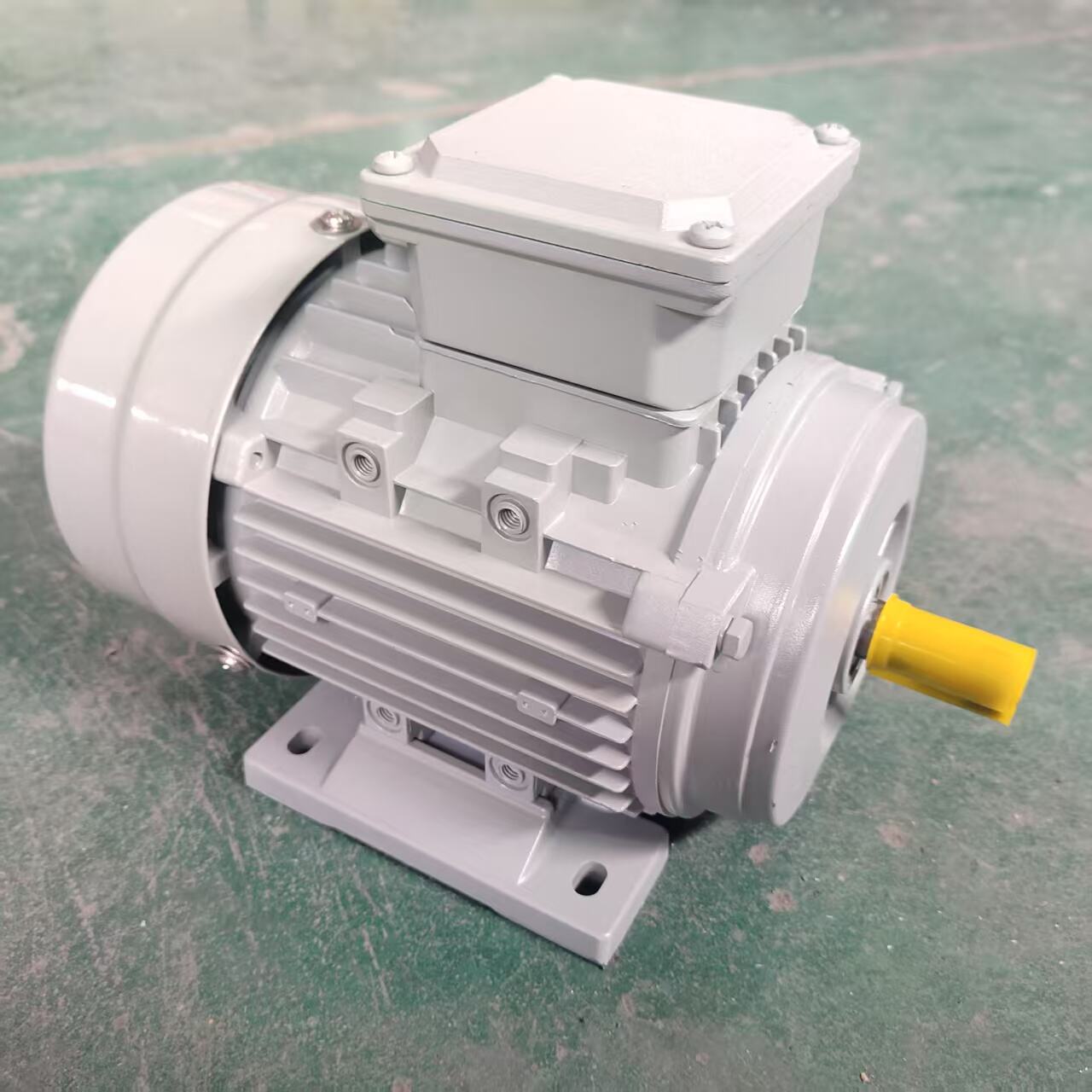

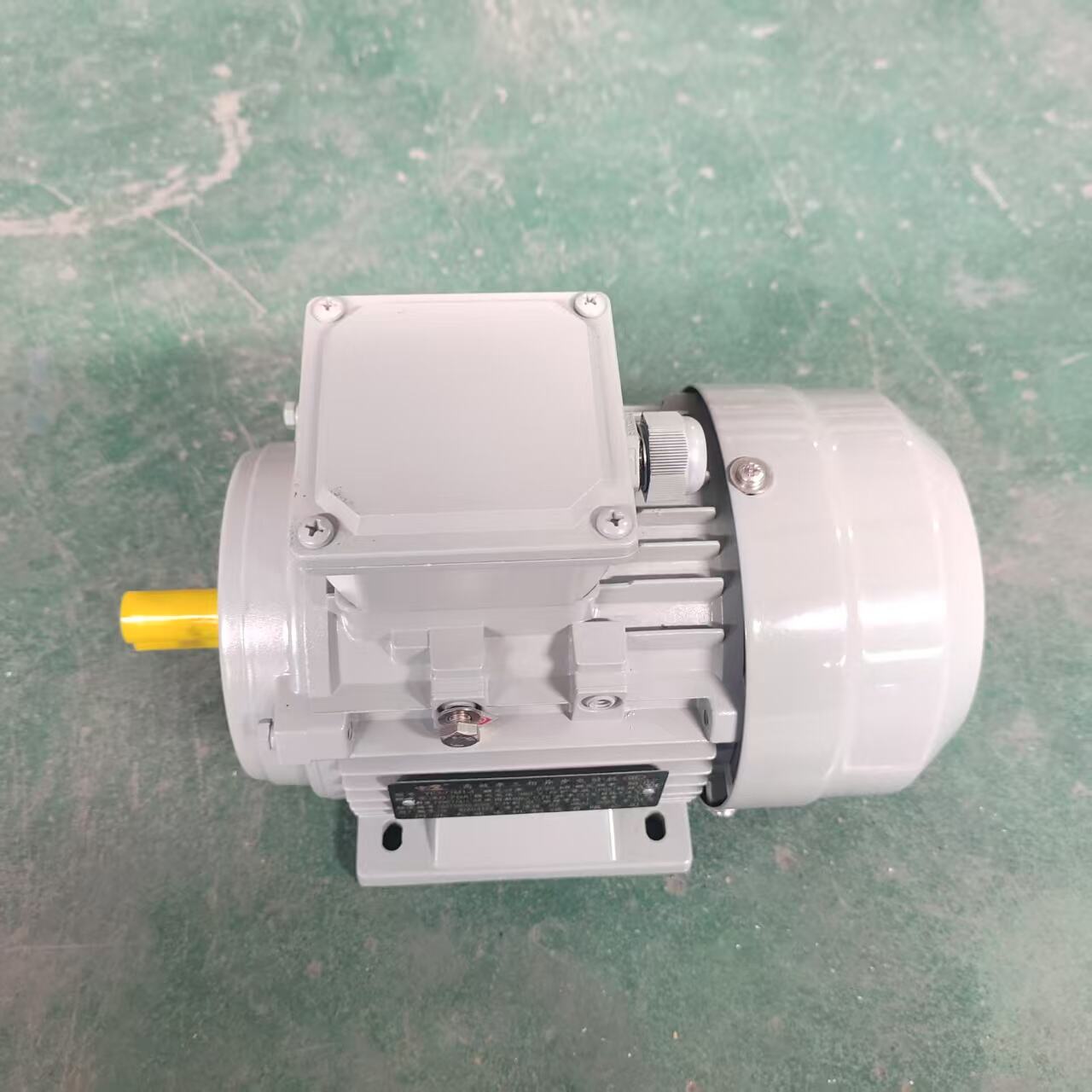

durable synchronous motor

The durable synchronous motor represents a pinnacle of electrical engineering excellence, designed to deliver consistent performance across demanding industrial applications. This advanced motor technology operates by maintaining a fixed relationship between the rotor speed and the supply frequency, ensuring precise control and exceptional reliability. Unlike asynchronous motors, the durable synchronous motor maintains constant speed regardless of load variations, making it ideal for applications requiring exact timing and coordination. The motor's construction features robust materials and advanced manufacturing techniques that enhance its longevity and resistance to harsh operating conditions. Key technological features include permanent magnet rotors or wound field systems that create strong magnetic fields, resulting in superior efficiency ratings often exceeding 95 percent. The durable synchronous motor incorporates advanced cooling systems, high-grade insulation materials, and precision-balanced components that minimize vibration and noise levels. These motors typically operate at power factor unity or leading power factor, which helps improve overall power system efficiency. The sophisticated control systems integrated into modern durable synchronous motors enable precise speed regulation, torque control, and seamless integration with automation systems. Applications span across numerous industries including manufacturing, power generation, marine propulsion, mining operations, and renewable energy systems. In manufacturing facilities, these motors drive critical equipment such as compressors, pumps, conveyors, and precision machinery where consistent performance is essential. Power generation applications utilize durable synchronous motors in hydroelectric plants, wind turbines, and backup generator systems. The marine industry relies on these motors for ship propulsion systems and onboard equipment that demands reliability in challenging maritime environments. Mining operations benefit from the motor's ability to withstand extreme conditions while maintaining optimal performance levels.