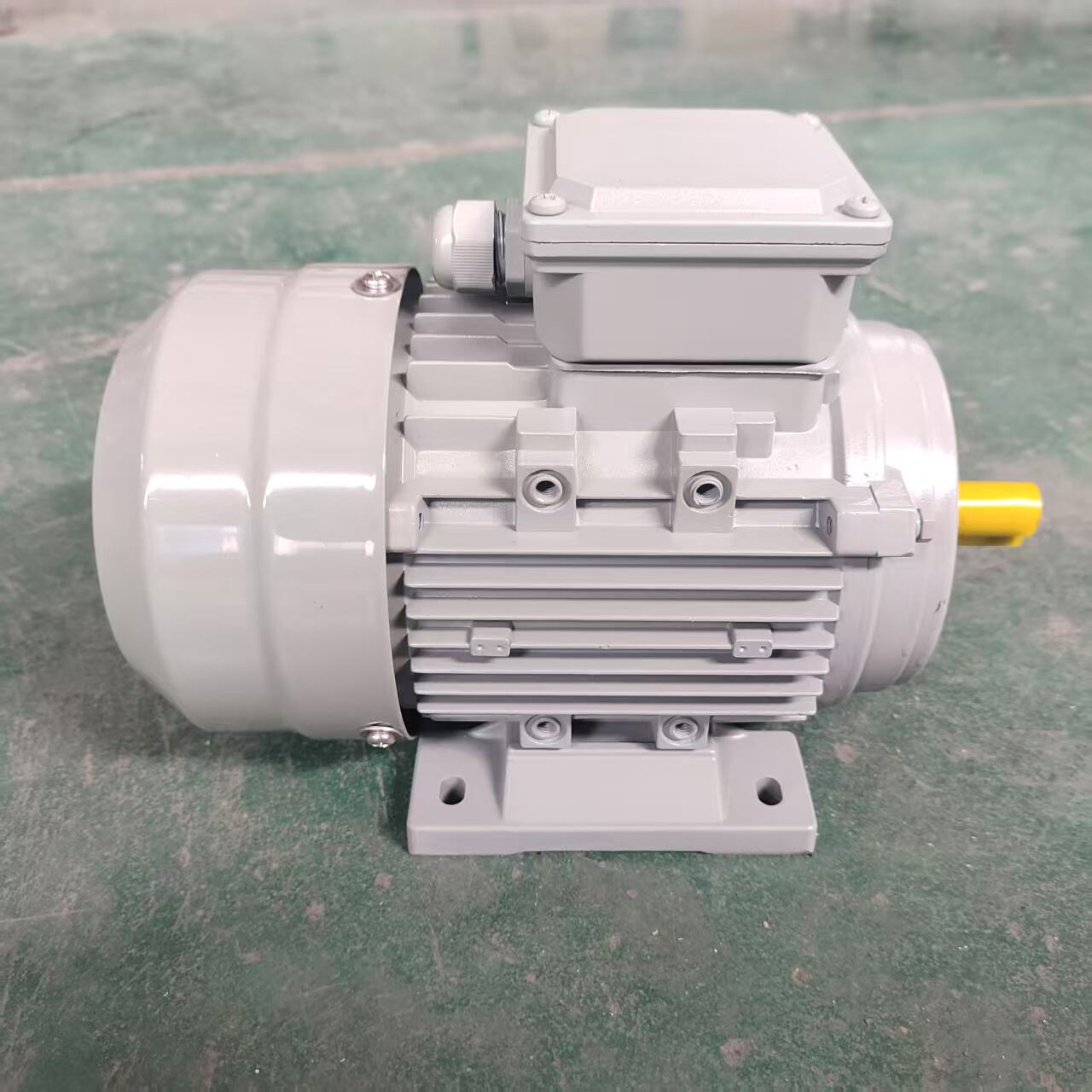

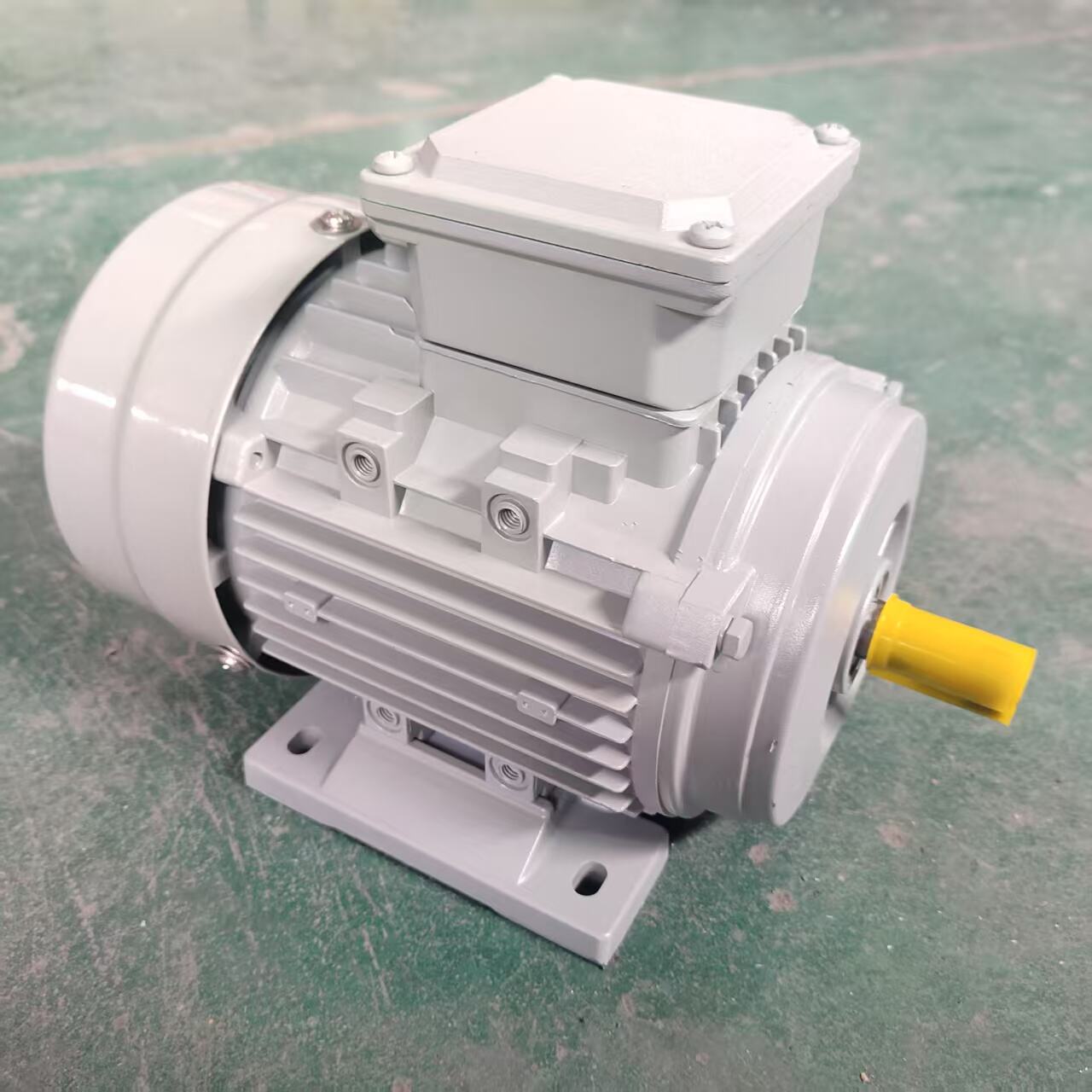

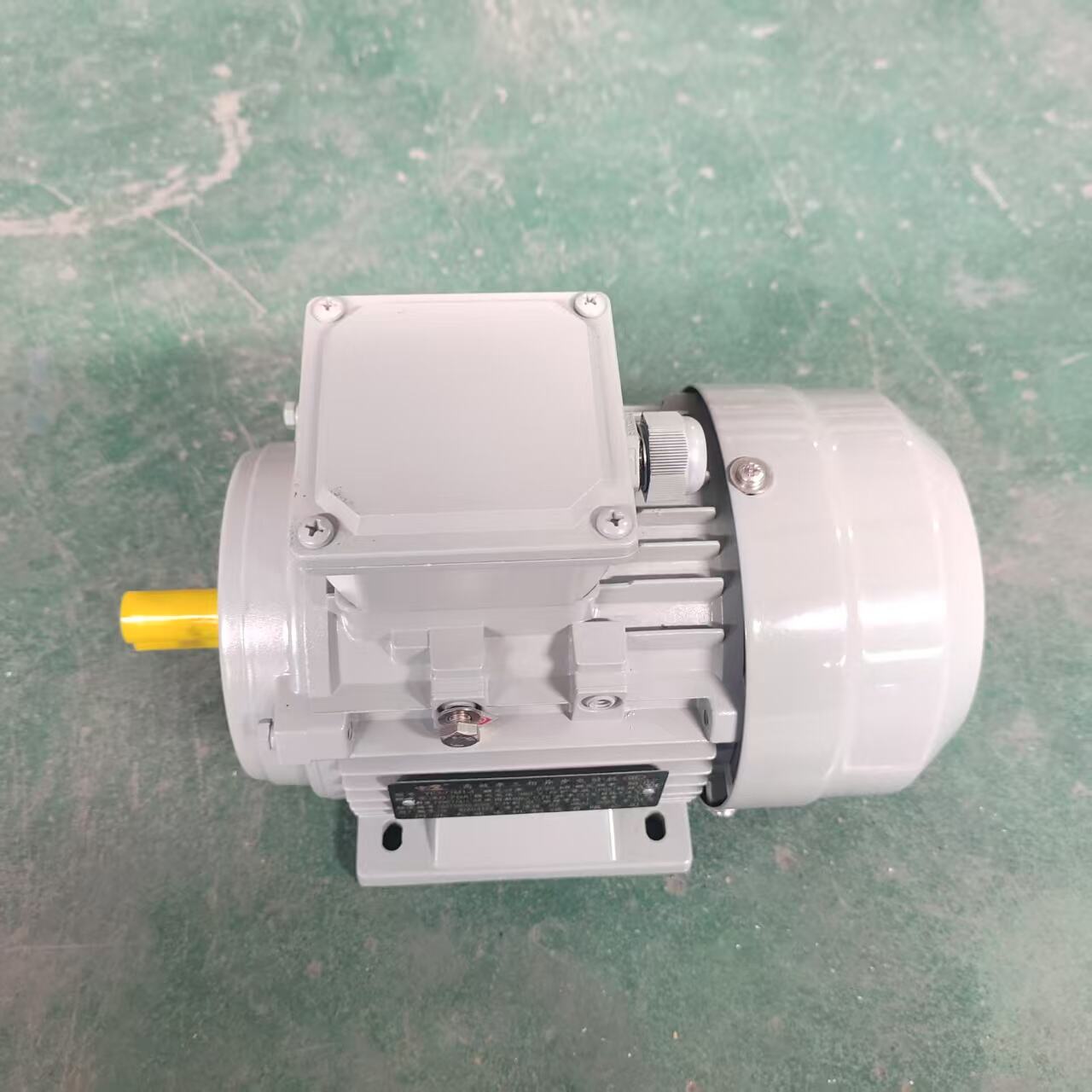

מנוע סינכרוני עמיד

המנוע הסינכרוני העמיד מייצג שיא בהנדסת חשמל מתקדמת, ונועד לספק ביצועים עקביים ביישומים תעשייתיים קשים. טכנולוגיית המנוע המתקדמת פועלת על ידי שמירה על קשר קבוע בין מהירות הרוטור לתדירות האספקה, ומבטיחה שליטה מדויקת ואמינות יוצאת דופן. בניגוד למנועים א-סינכרוניים, המנוע הסינכרוני העמיד שומר על מהירות קבועה ללא תלות בשינויי עומס, מה שהופך אותו אידיאלי ליישומים הדורשים סנכרון ודקדוק מדויקים. בניית המנוע כוללת חומרים עמידים וטכניקות ייצור מתקדמות שמשפרות את אורך חייו ואת עמידותו בתנאי עבודה קשים. תכונות טכנולוגיות עיקריות כוללות רוטורים עם מגנטים קבועים או מערכות שדה ملفופות שיוצרות שדות מגנטיים חזקים, מה שמייצר דירוגי יעילות גבוהים במיוחד, לעתים קרובות מעל 95 אחוז. המנוע הסינכרוני העמיד כולל מערכות קירור מתקדמות, חומרי בידוד איכותיים ורכיבים מאוזנים בדיוק שמזערים את רמות הרטט והרעש. מנועים אלו פועלים בדרך כלל בפקטור הספק של 1 או בפאזה מובילה, מה שמסייע לשפר את יעילות מערכת החשמל הכוללת. מערכות הבקרה המורכבות המשולבות במנועים סינכרוניים עמידים מודרניים מאפשרות התאמה מדויקת של מהירות, שליטת מומנט ושילוב חלקות למערכות אוטומציה. היישומים משתרעים על פני מגוון תעשיות, ביניהן ייצור, ייצור חשמל, דחיפה ימית, פעולות כרייה ומערכות אנרגיה מתחדשת. במתקני ייצור, מונעים מנועים אלו ציוד קריטי כגון מדחסים, משאבות, מסועים ומכשור מדויק שבו ביצועים עקביים הם חיוניים. ביישומי ייצור חשמל, נעשה שימוש במנועים סינכרוניים עמידים בתחנות הידרו-אלקטריות, טורבינות רוח ומערכות גנרטור לגיבוי. התעשייה הימית סומכת על מנועים אלו למערכות דחיפה של ספינות וציוד פנימי הדורש אמינות בסביבות ימיות מאתגרות. תעשיות כרייה נהנות מיכולת המנוע לעמוד בתנאים קיצוניים תוך שמירה על ביצועים אופטימליים.