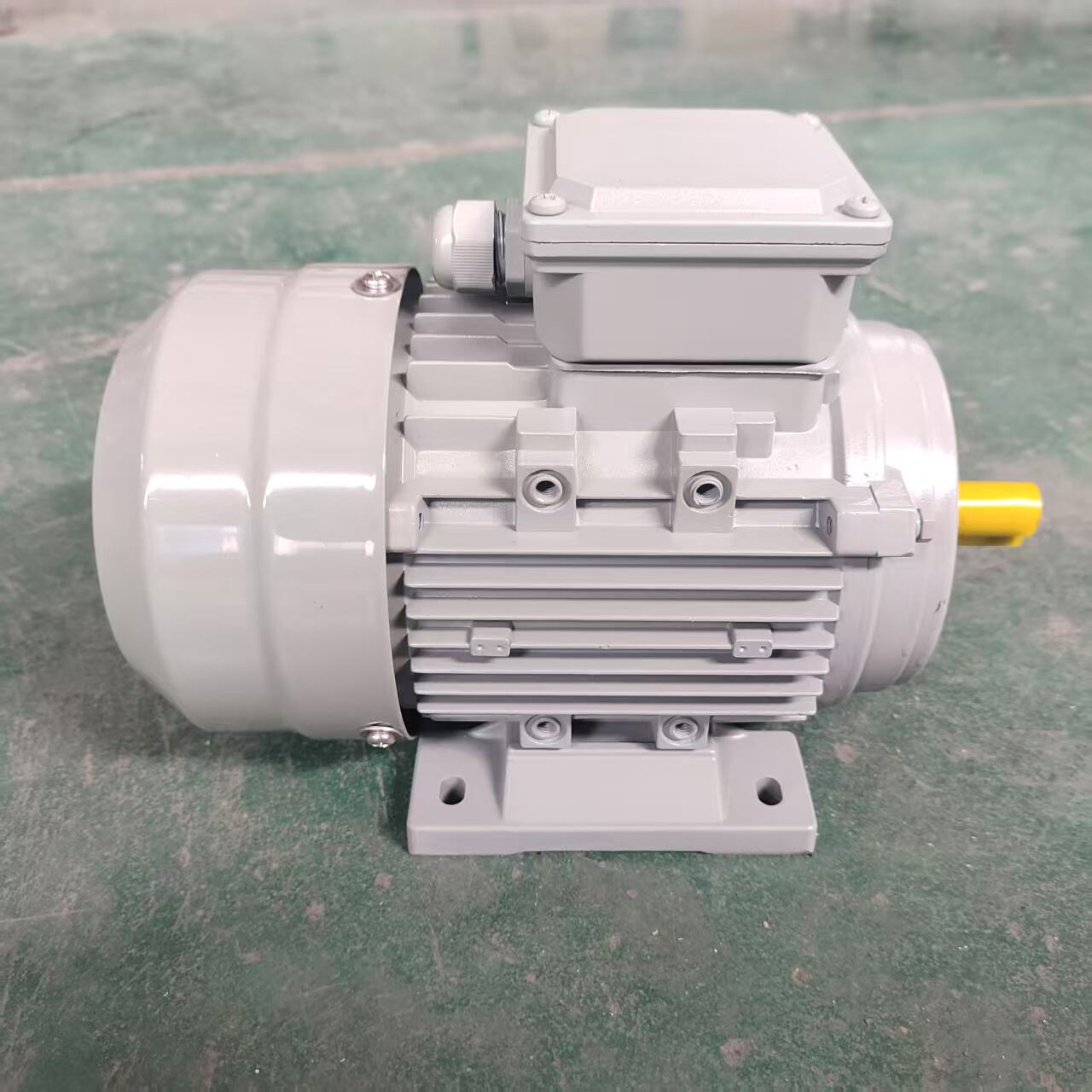

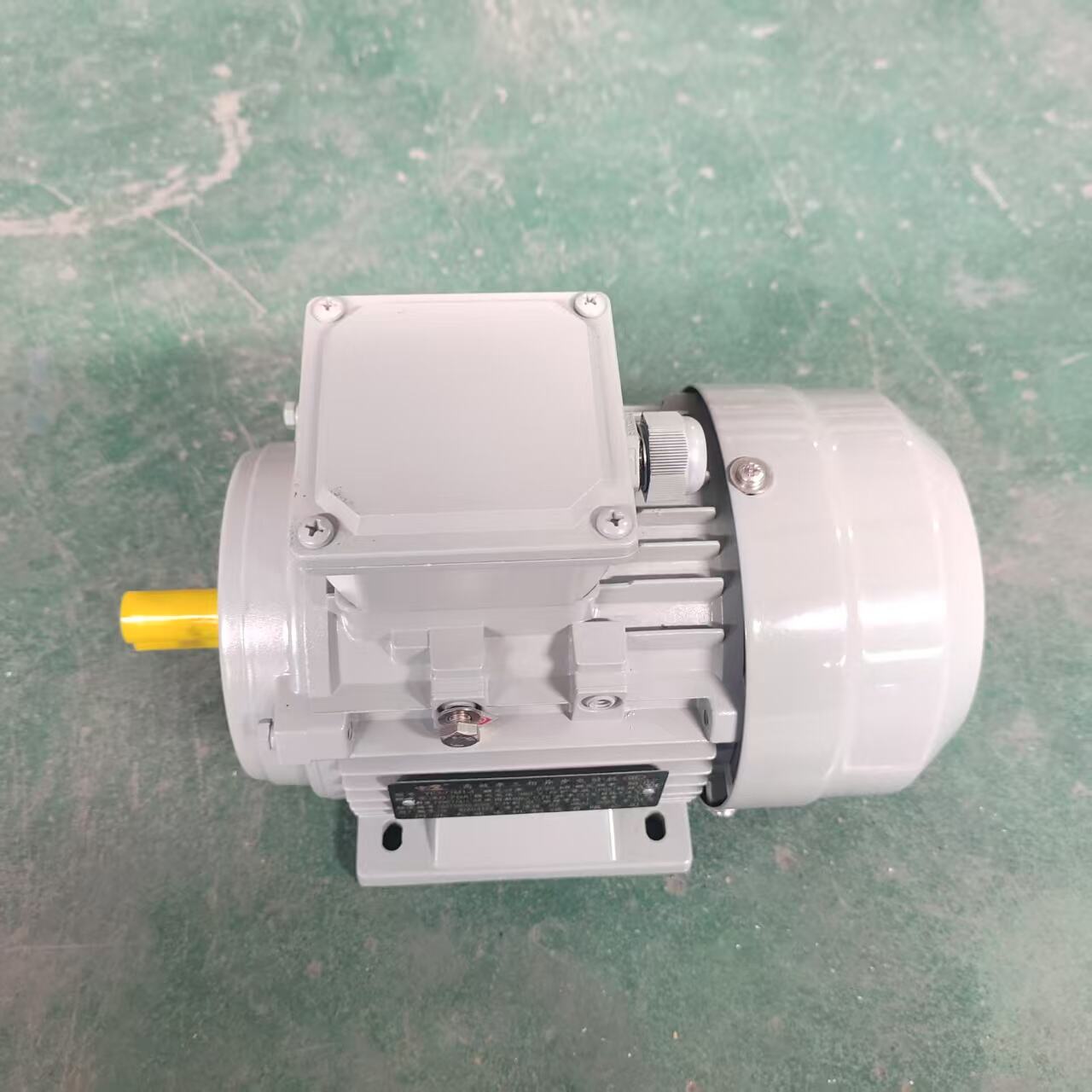

המנוע הסינכרוני החדש ביותר

המנוע הסינכרוני החדש ביותר מייצג התקדמות מהפכנית בטכנולוגיית מנועים חשמליים, ומציע ביצועים ייחודיים וכفاءה ללא תחרות ביישומים תעשייתיים מגוונים. מנוע זהanguardisti עושה שימוש בטכנולוגיית מנוע סינכרוני עם מגנט קבוע (PMSM) בשילוב עם אלגוריתמי בקרה מתקדמים כדי להשיג צפיפות עוצמה גבוהה ודיוק מיטבי בתפעול. המנוע הסינכרוני החדש ביותר כולל מגנטים קבועים מיסודות נדירים שמשמרים עוצמת שדה מגנטית יציבה, מבטיחים מומנט יציב וצריכת אנרגיה מופחתת. פונקציות עיקריות כוללות שליטה במהירות משתנה בדיוק יוצא דופן, יכולת בלימת שיקום, ואינטגרציה חלקה עם מערכות אוטומציה מודרניות. יחידת הבקרה החכמה של המנוע מנטרת פרמטרים תפעוליים בזמן אמת, ומאפשרת התאמה אוטומטית של הביצועים על מנת למקסם את היעילות ולמנוע חימום יתר. תכונות טכנולוגיות כוללות מקודדים בדרגת רזולוציה גבוהה לצורך משוב מדויק של מיקום, מערכות ניהול תרמי מתקדמות, וחומרי בנייה עמידים המסוגלות לעמוד בסביבות תעשייתיות קשות. המנוע הסינכרוני החדש ביותר משתמש באלגוריתמי בקרה וקטורית מתוחכמים המאפשרים שליטה עצמאית במומנט ובשטף, מה שמוביל לתפעול חלק בכל טווח המהירויות. היישומים משתרעים על פני ייצור רכב, רובוטיקה, מכונות CNC, טורבינות רוח, כלי רכב חשמליים, וציוד ייצור מדויק. העיצוב הדחוס של המנוע מאפשר התקנה קלה בסביבות עם אילוץ של שטח, תוך כדי שמספק תפוקת עוצמה מרבית. יכולות אבחון מתקדמות מספקות התראות לאתחזון חיזוי, ובכך מפחיתות את זמני העצירה ואת עלויות התפעול. המנוע הסינכרוני החדש ביותר מציג תיאום אלקטרומגנטי משופר, ובכך מפחית הפרעות בציוד אלקטרוני רגיש. הבנייה המודולרית שלו מקלה על תחזוקה מהירה והחלפת רכיבים, ומבטיחה הפרעות מינימליות בייצור. המנוע תומך במספר פרוטוקולי תקשורת, ומאפשר אינטגרציה חלקה למערכות בקרה תעשייתיות קיימות ופלטפורמות של IoT. היבטים סביבתיים כוללים הפחתת הדבקה הפחמנית באמצעות שיפור היעילות, וכן שימוש בחומרים ניתנים להחלפה בתהליך הבנייה.