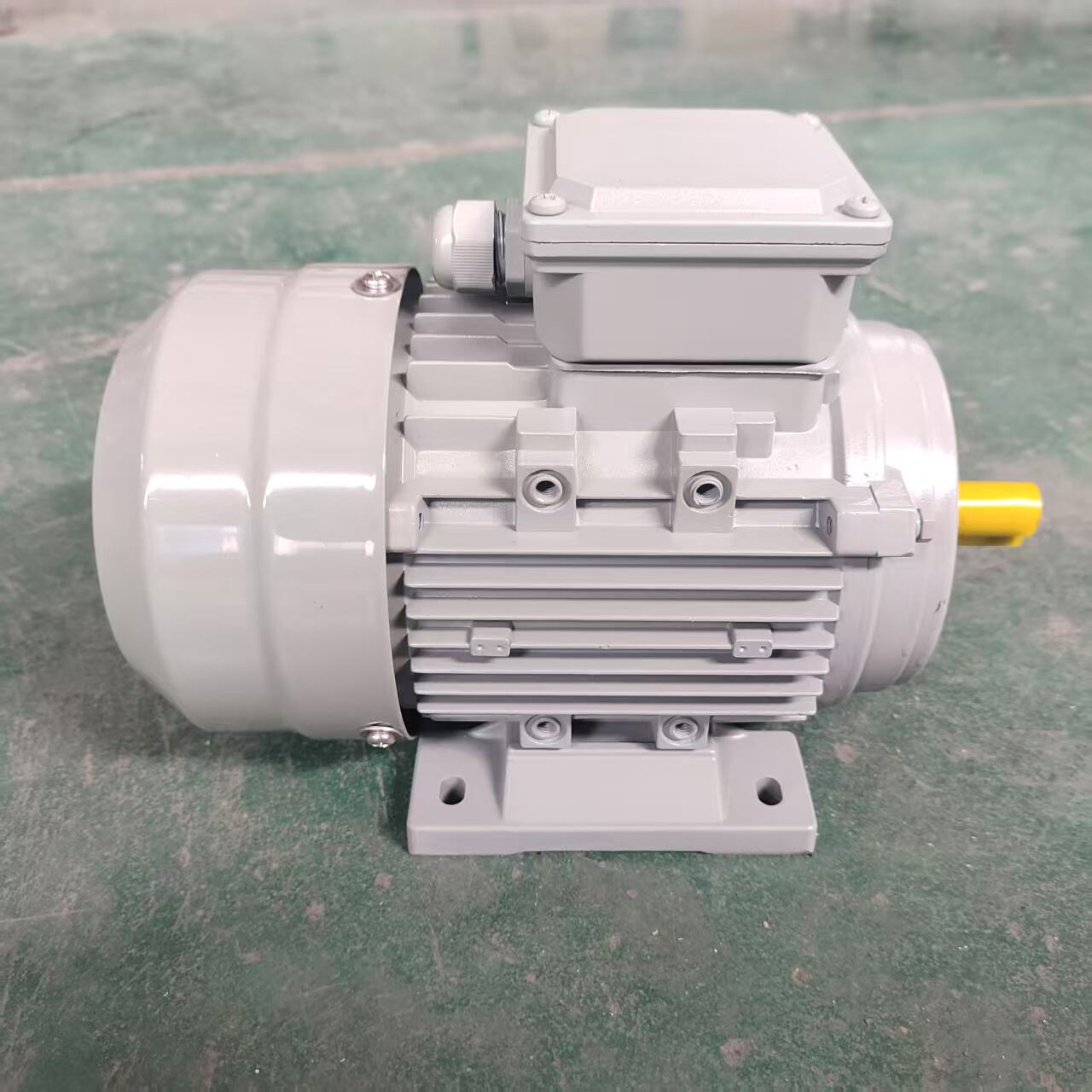

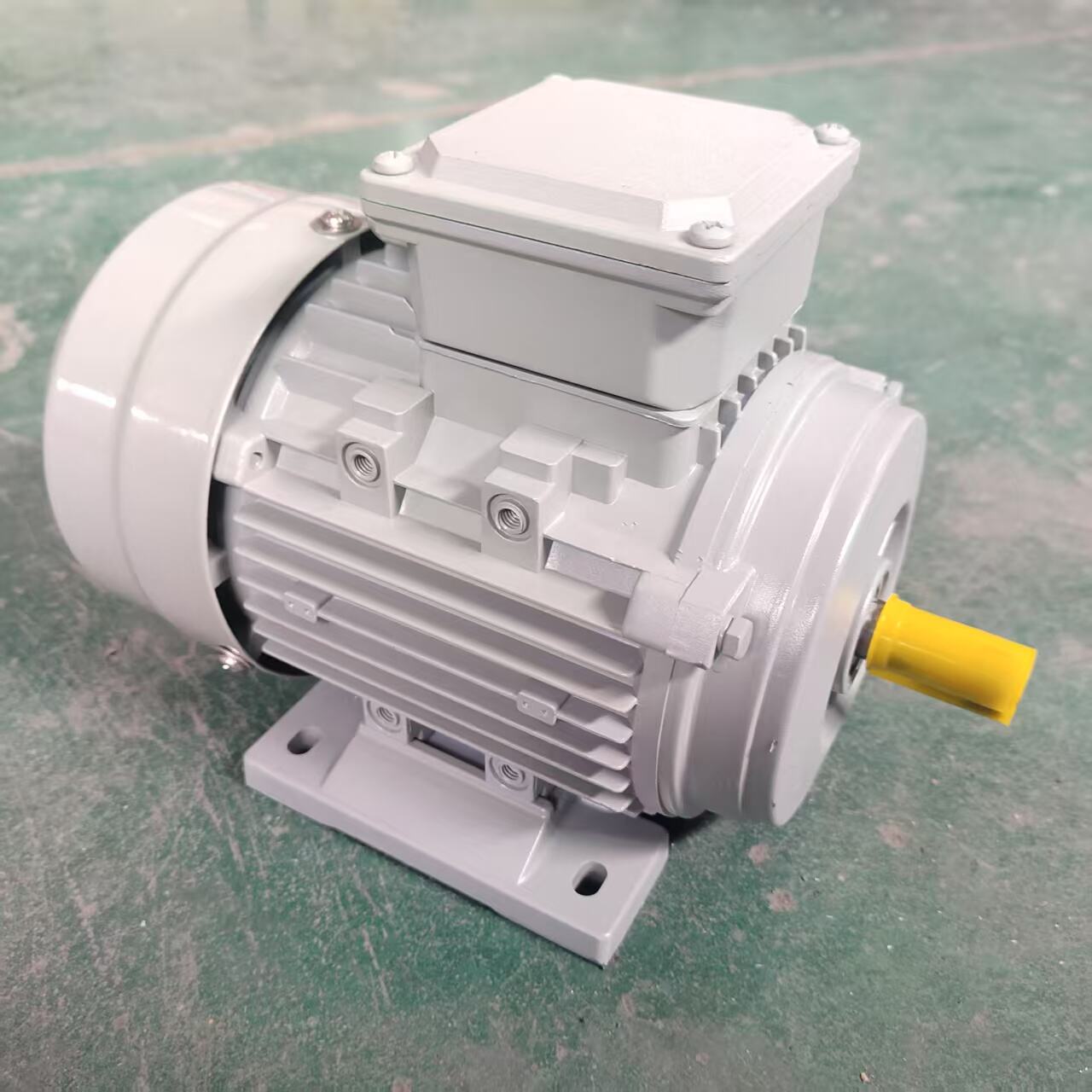

high quality synchronous motor

A high quality synchronous motor represents a pinnacle of electrical engineering excellence, delivering precise speed control and exceptional operational reliability across diverse industrial applications. This advanced motor technology operates by maintaining perfect synchronization between the rotating magnetic field and the rotor speed, ensuring consistent performance regardless of load variations. The high quality synchronous motor incorporates state-of-the-art materials, precision manufacturing techniques, and sophisticated control systems to deliver superior efficiency ratings that often exceed 95 percent. These motors feature robust construction with premium-grade bearings, advanced insulation systems, and precisely balanced rotors that minimize vibration and noise during operation. The technological architecture includes permanent magnet rotors or wound rotor designs, depending on specific application requirements, with each configuration optimized for maximum power density and thermal management. Modern high quality synchronous motor designs integrate smart monitoring capabilities, allowing real-time assessment of operational parameters such as temperature, vibration levels, and electrical consumption. The motor housing utilizes corrosion-resistant materials and advanced cooling systems to ensure longevity even in harsh industrial environments. Variable frequency drive compatibility enables seamless integration with automated control systems, providing operators with precise speed regulation and energy optimization capabilities. These motors demonstrate exceptional starting torque characteristics while maintaining smooth acceleration profiles that protect connected machinery from mechanical stress. The high quality synchronous motor design philosophy emphasizes reduced maintenance requirements through superior component selection and engineering precision, resulting in extended operational lifespans that can exceed twenty years under proper conditions. Advanced electromagnetic design reduces harmonic distortion and improves power factor correction, contributing to overall system efficiency and reduced electrical infrastructure requirements.