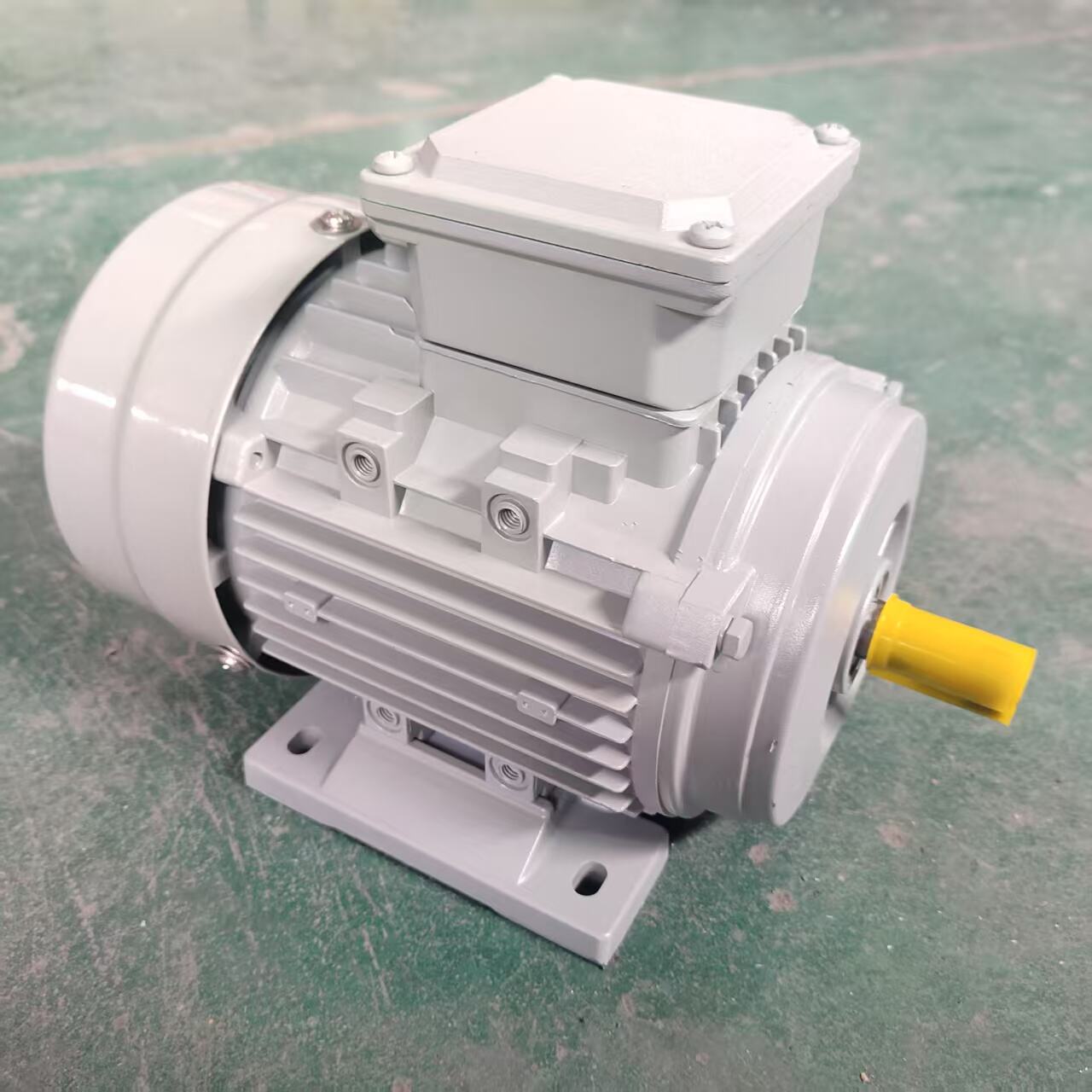

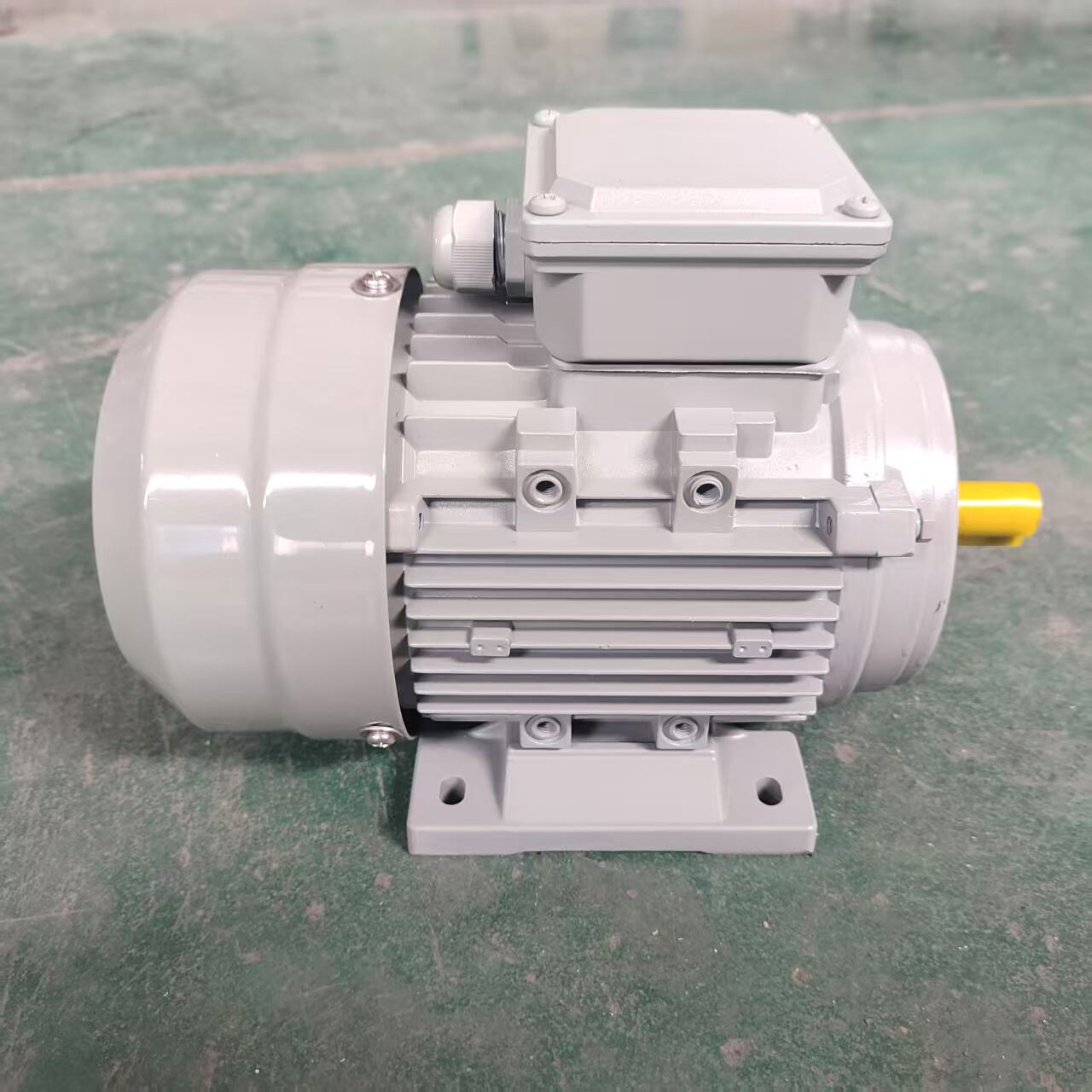

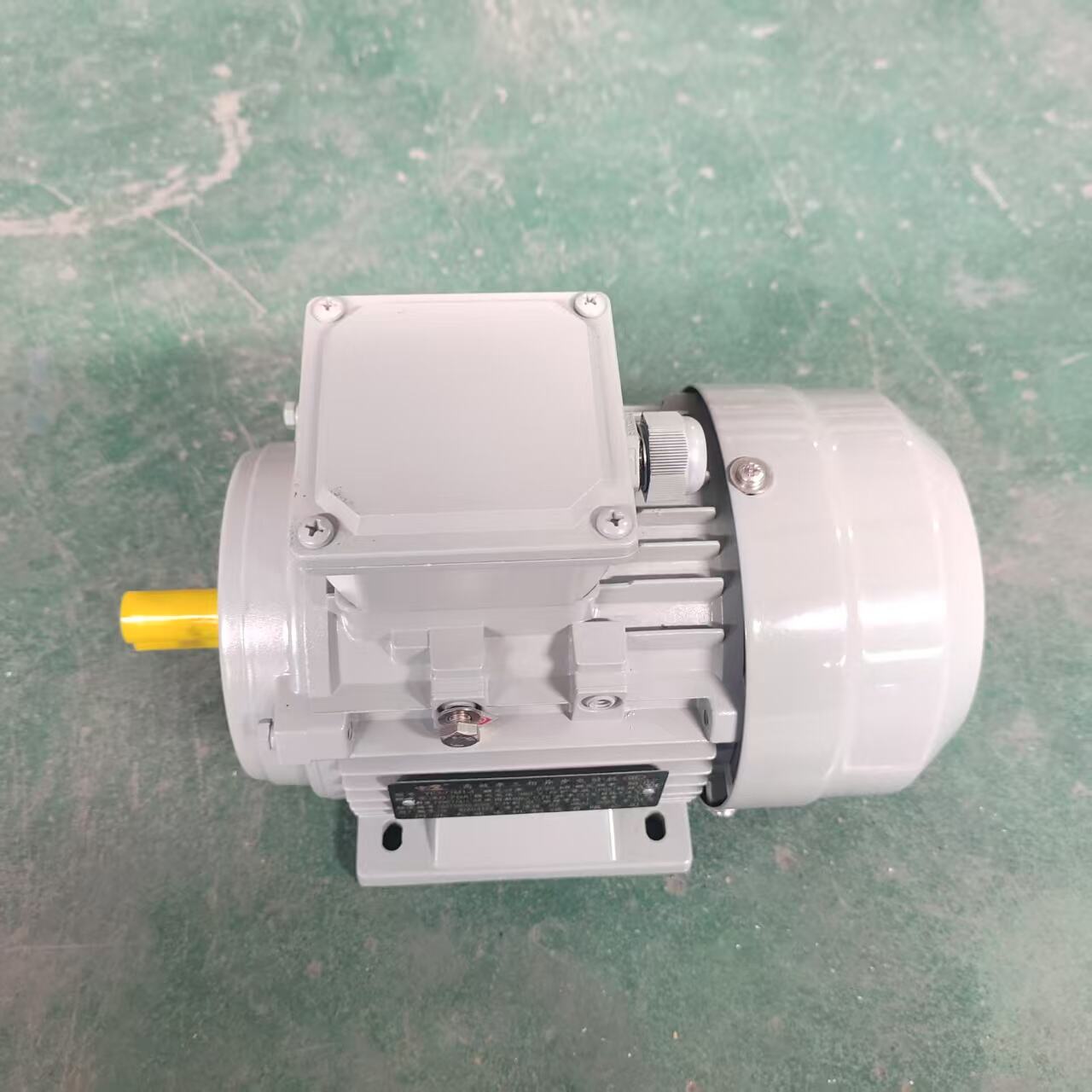

billig synkronmotor

En billig synkronmotor repræsenterer en fremragende balance mellem ydelse og pris i elmotorindustrien. Disse motorer fungerer ved en konstant hastighed, der forbliver synkroniseret med vekselstrømmens frekvens, hvilket gør dem ideelle til applikationer, hvor præcis hastighedsregulering er nødvendig. I modsætning til asynkronmotorer bevarer billige synkronmotorer deres rotationshastighed uanset belastningsvariationer inden for deres driftsområde. Det grundlæggende princip bag disse motorer omfatter interaktionen mellem et roterende magnetfelt, som statorviklingerne producerer, og et magnetfelt, som rotoren genererer. Denne synkronisering sikrer konsekvent ydelse under forskellige driftsbetingelser. Moderne billige synkronmotorer integrerer avancerede materialer og fremstillingsmetoder, der reducerer produktionsomkostninger, samtidig med at pålideligheden bevares. Rotoren indeholder typisk permanente magneter eller elektromagneter, som skaber det nødvendige magnetfelt for synkron drift. Disse motorer har fremragende effektfaktor-egenskaber og fungerer ofte ved enheds-effektfaktor eller endda forudgående effektfaktorforhold. De teknologiske egenskaber ved billige synkronmotorer inkluderer robust konstruktion, effektive varmeafledningssystemer og optimerede magnetiske kredsløb. Mange modeller har børstefrie design, der eliminerer vedligeholdelseskrav forbundet med traditionelle børstetyper motorer. Styresystemerne for disse motorer er blevet stadig mere sofistikerede og tilbyder præcis hastighedsregulering og momentstyring. Anvendelsesområder for billige synkronmotorer dækker mange industrier, herunder produktionautomatisering, HVAC-systemer, transportbånd og præcisionsmaskineri. I industrielle installationer driver disse motorer pumper, kompressorer og ventilatorer, hvor konstant hastighedsdrift er afgørende. Automobilindustrien anvender billige synkronmotorer i elbilapplikationer, servostyringer og forskellige hjælpekomponenter. Forbrugerapparater såsom vaskemaskiner, opvaskemaskiner og aircondition-anlæg benytter ofte disse motorer på grund af deres pålidelighed og effektivitet. Sektoren for medicinsk udstyr er afhængig af billige synkronmotorer til enheder, der kræver præcis positionering og stille drift.