Tilpasning i topklasse til specialiserede industrielle applikationer

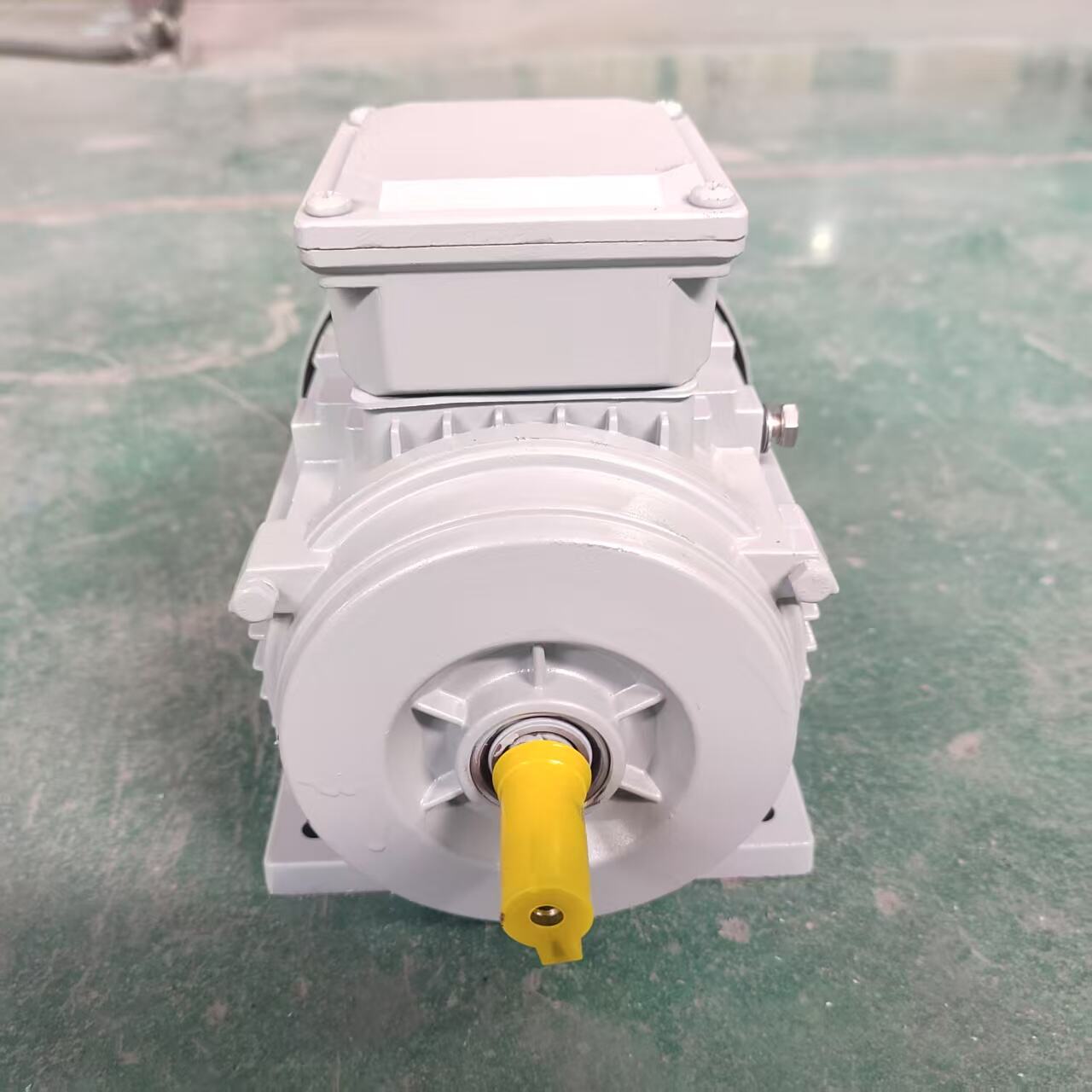

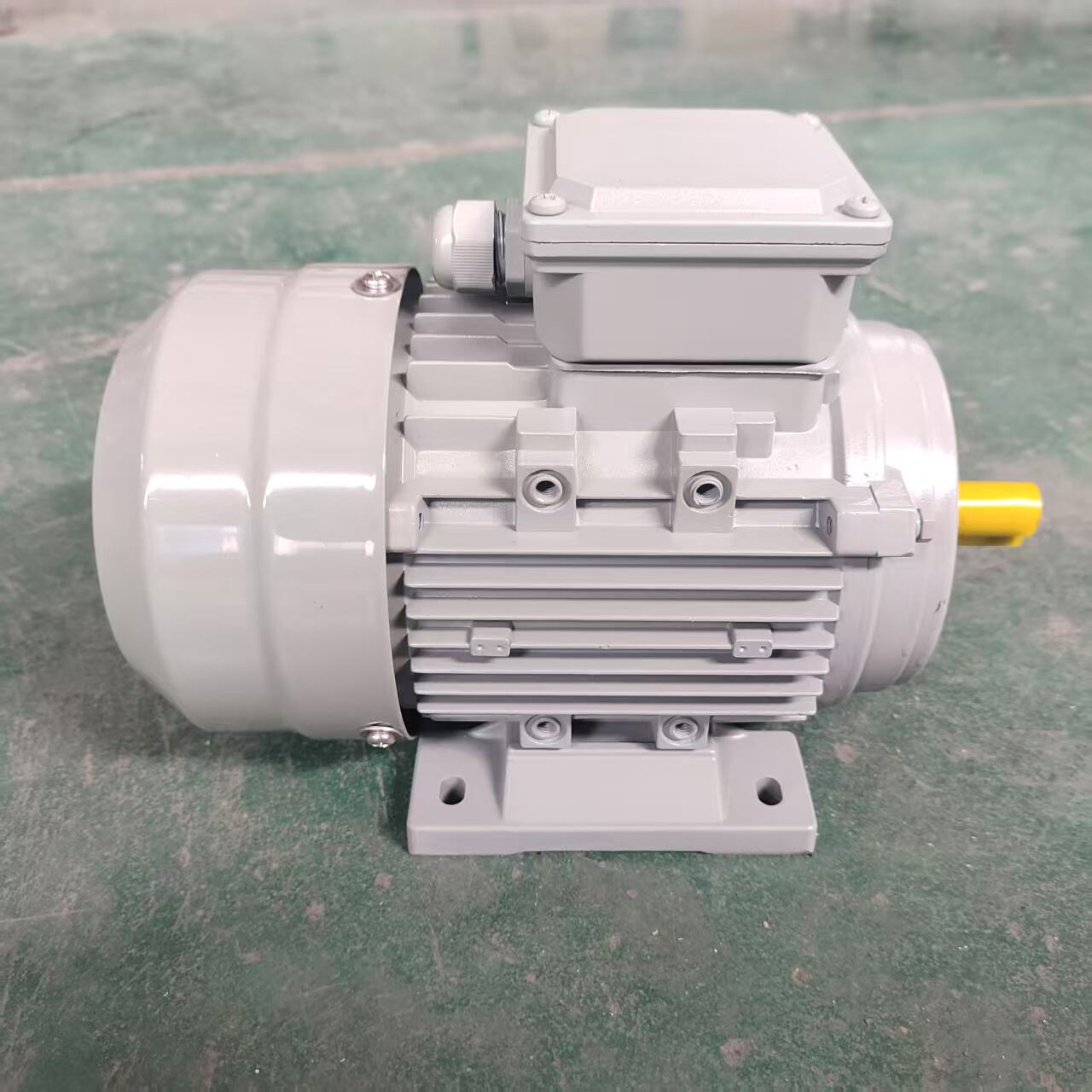

Den specialtilpassede synkronmotor repræsenterer toppen af applikationsspecifik designeksklusive og tilbyder uslåelig fleksibilitet for at opfylde de mest krævende industrielle behov. Tilpasningsprocessen starter med en omfattende analyse af anvendelsen, hvor ingeniører vurderer driftsparametre, miljøforhold, belastningsegenskaber og ydekrav for at udvikle optimale motorspecifikationer. Denne detaljerede tilgang sikrer, at alle aspekter af motordesignet passer perfekt til de specifikke krav til applikationen – fra drejningsmomentkurver og hastighedsintervaller til monteringskonfigurationer og beskyttelsesniveauer mod miljøpåvirkninger. Materialevalg spiller en afgørende rolle i tilpasningsprocessen, hvor ingeniører vælger mellem et bredt udvalg af højtkvalitetsmaterialer, herunder permanente magneter med sjældne jordarter, specialstållegninger og avancerede isolationssystemer, der optimerer ydelsen under specifikke driftsforhold. Den specialtilpassede synkronmotor kan konfigureres til ekstreme miljøforhold, herunder høje temperaturer, ætsende atmosfærer, eksplosive omgivelser og marin anvendelse, gennem specialiserede karmmaterialer, tætningsløsninger og beskyttende belægninger. Mekaniske tilpasningsmuligheder omfatter forskellige akselkonfigurationer, monteringsarrangementer, kølesystemer og vibrationsdæmpende funktioner, som sikrer optimal integration med eksisterende udstyr og faciliteter. Elektriske tilpasningsmuligheder omfatter spændingsklassificeringer, frekvenskrav, effektfaktorspecifikationer og kontrolgrænseflader, der matcher den eksisterende facilitets infrastruktur og driftspræferencer. Motorens formfaktor kan optimeres til installationer med begrænsede pladsforhold, samtidig med at fuld ydelse bevares gennem innovative designløsninger og komponentopsætning. Særlige anvendelser såsom traktionsmotorer, marine fremdriftssystemer, anlæg til vedvarende energi og præcisionsproduktionsudstyr drager fordel af de omfattende tilpasningsmuligheder, der er tilgængelige med synkronmotorteknologi. Kvalitetssikring gennem hele tilpasningsprocessen omfatter strenge testprotokoller, der bekræfter ydelsen under reelle driftsforhold, og dermed sikres det, at den leverede motor opfylder eller overgår alle specificerede krav. Efterleveringssupport omfatter omfattende dokumentation, træningsprogrammer og løbende teknisk assistance, som hjælper operatører med at maksimere fordelene ved deres investering i en specialtilpasset synkronmotor. Tilpasningseksklusive udvides til fremtidige modificeringsmuligheder, så motorer kan opgraderes eller omkonfigureres efterhånden som driftskrav udvikler sig, hvilket giver langsigtede værdi og tilpasningsevne, der retfærdiggør den oprindelige investering i specialtilpasset motorteknologi.