المحرك الكهربائي غير المتزامن: الأعطال الشائعة والإصلاحات السريعة

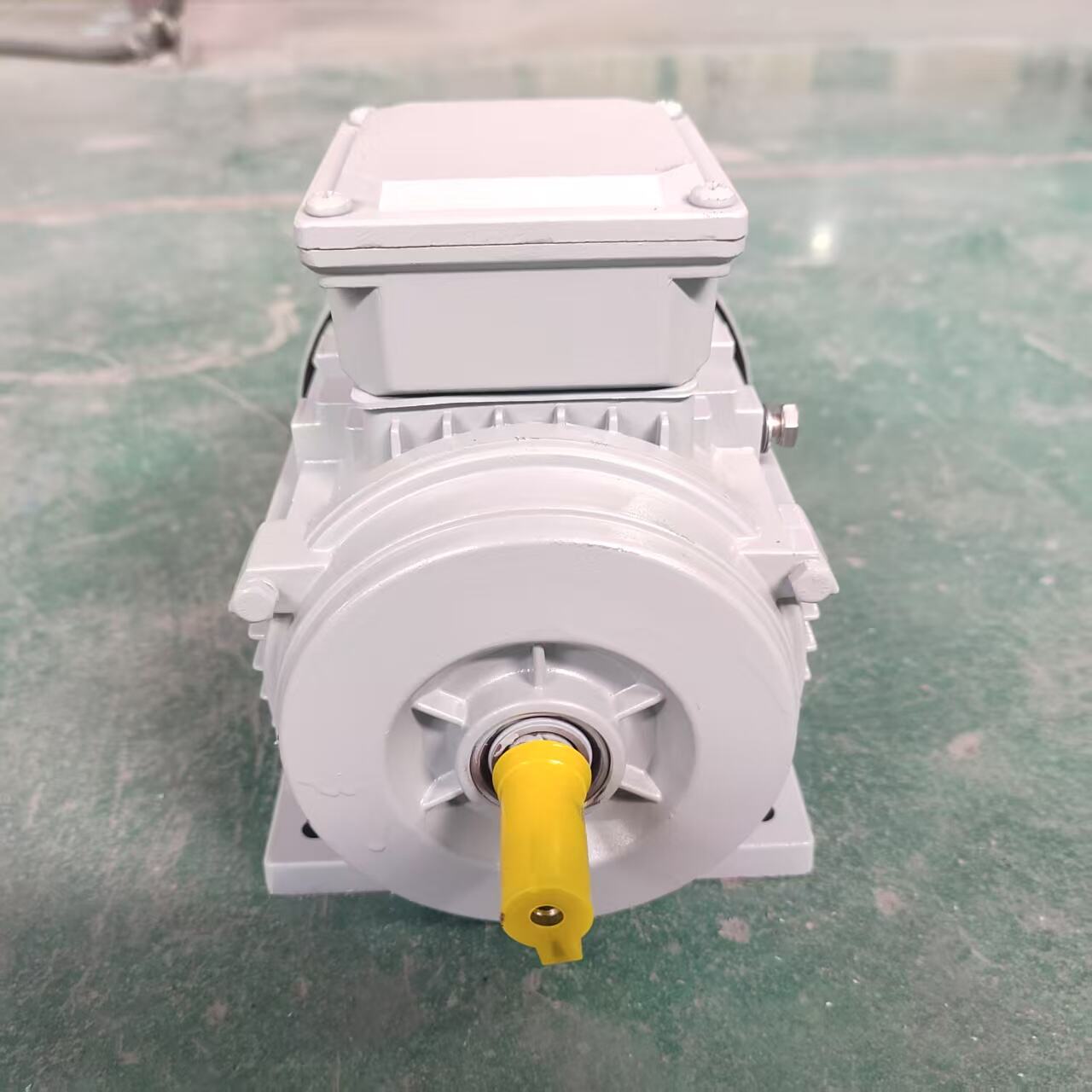

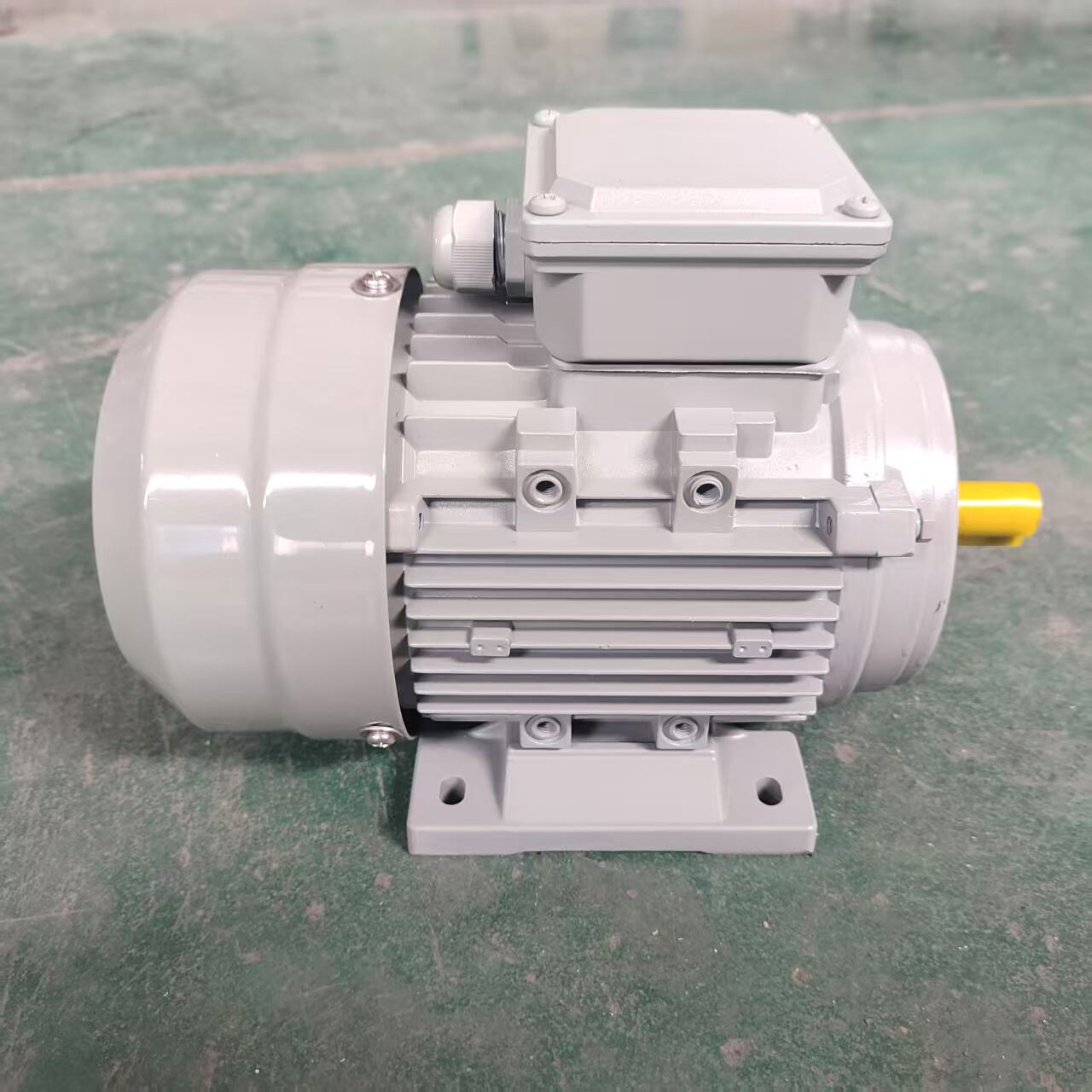

فهم الميكانيكا وراء تشغيل المحرك غير المتزامن، تُعد المحركات الكهربائية غير المتزامنة، والمعروفة أيضًا باسم محركات الحث، العمود الفقري للآلات والمعدات الصناعية في جميع أنحاء العالم. تقوم هذه المحركات القوية بتحويل الطاقة الكهربائية إلى...

عرض المزيد