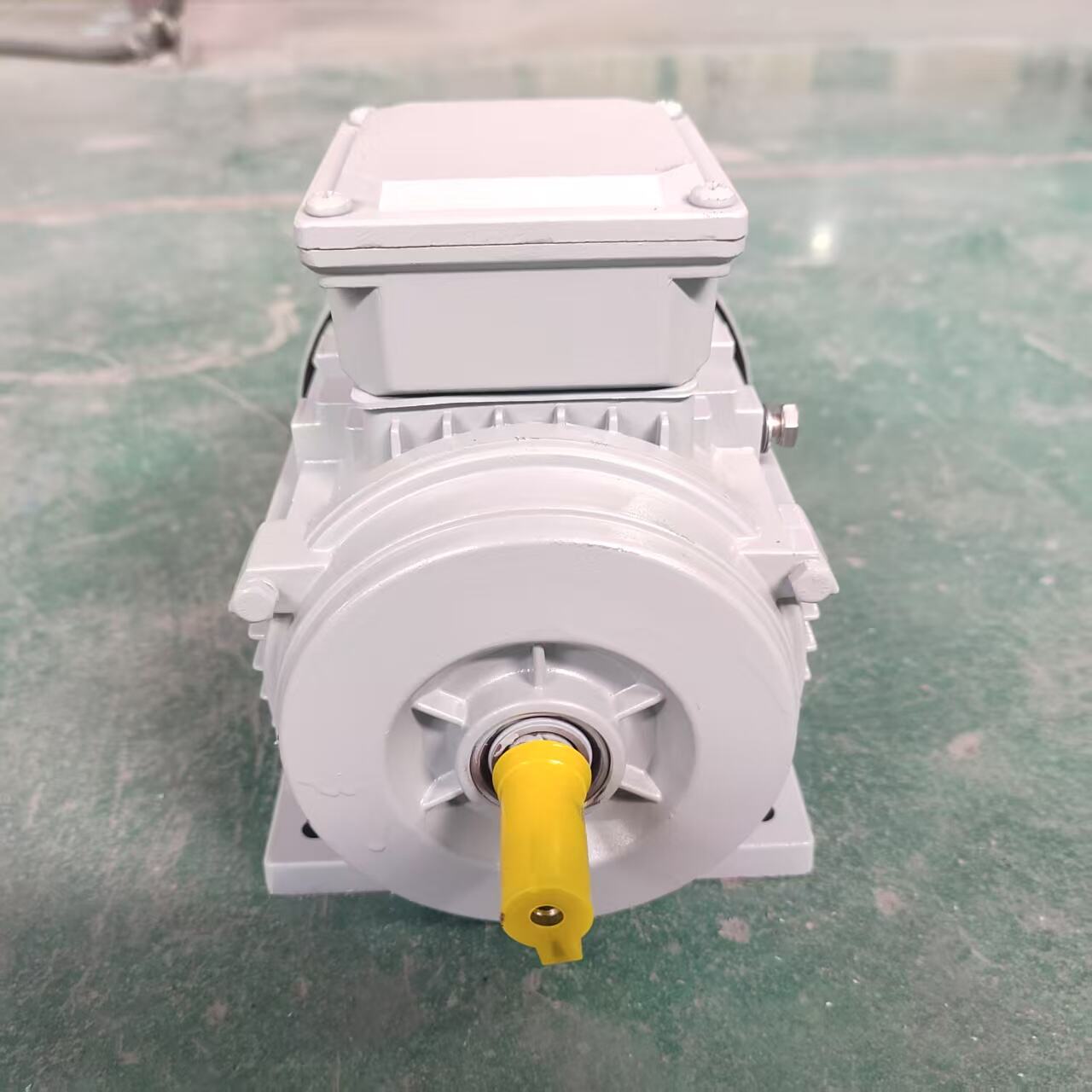

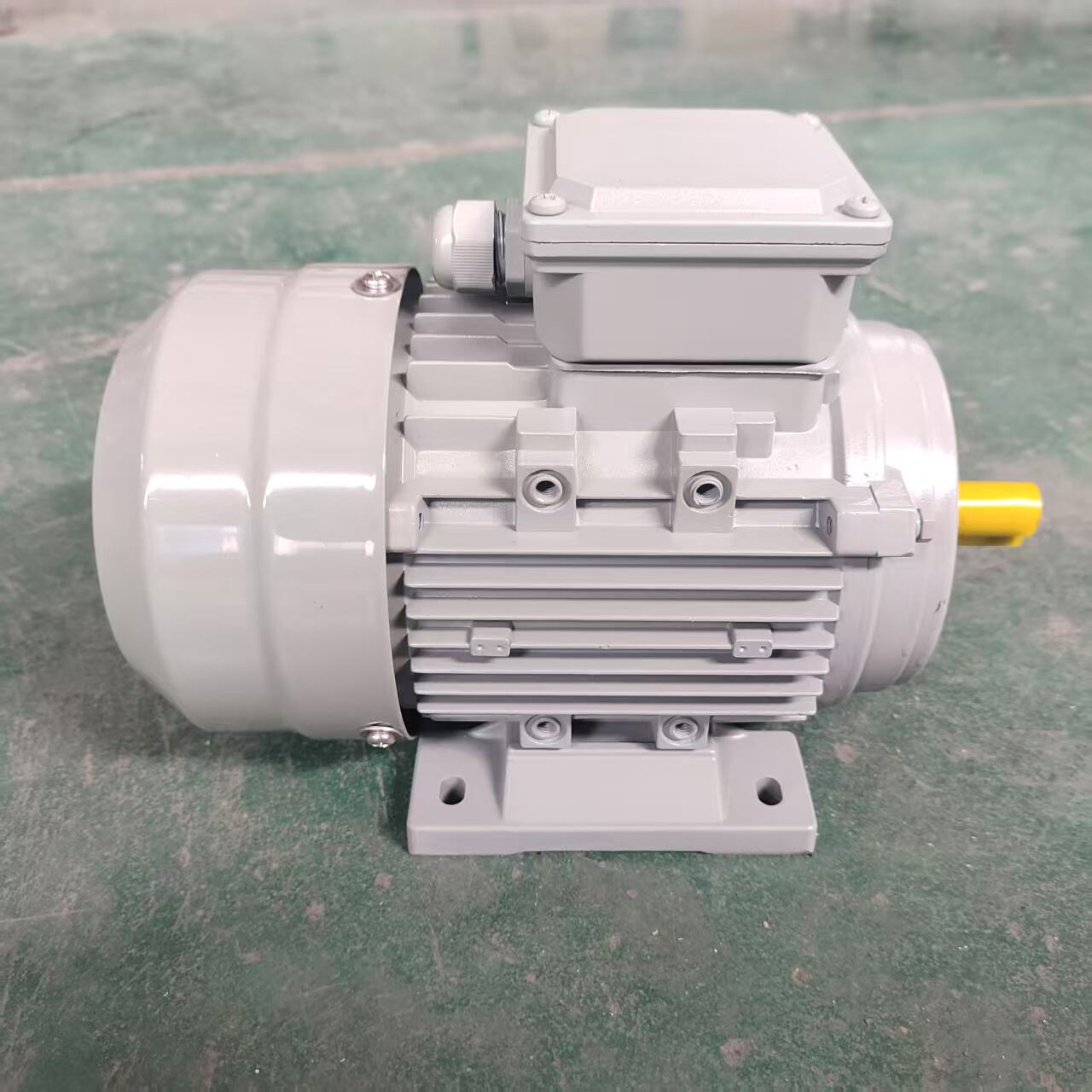

Customization Excellence for Specialized Industrial Applications

The customized synchronous motor represents the pinnacle of application-specific design excellence, offering unmatched flexibility to meet the most demanding industrial requirements. The customization process begins with comprehensive application analysis where engineers evaluate operational parameters, environmental conditions, load characteristics, and performance expectations to develop optimal motor specifications. This detailed approach ensures that every aspect of the motor design aligns perfectly with specific application requirements, from torque curves and speed ranges to mounting configurations and environmental protection levels. Material selection plays a crucial role in the customization process, with engineers choosing from a wide range of premium materials including rare earth permanent magnets, specialized steel alloys, and advanced insulation systems that optimize performance for specific operating conditions. The customized synchronous motor can be configured for extreme environmental conditions including high temperatures, corrosive atmospheres, explosive environments, and marine applications through specialized housing materials, sealing systems, and protective coatings. Mechanical customization options include various shaft configurations, mounting arrangements, cooling systems, and vibration dampening features that ensure optimal integration with existing equipment and facilities. Electrical customization encompasses voltage ratings, frequency requirements, power factor specifications, and control interface options that match existing facility infrastructure and operational preferences. The motor's form factor can be optimized for space-constrained installations while maintaining full performance capabilities through innovative design approaches and component arrangement. Special applications such as traction motors, marine propulsion systems, renewable energy installations, and precision manufacturing equipment benefit from the extensive customization capabilities available with synchronous motor technology. Quality assurance throughout the customization process includes rigorous testing protocols that verify performance under actual operating conditions, ensuring that the delivered motor meets or exceeds all specified requirements. Post-delivery support includes comprehensive documentation, training programs, and ongoing technical assistance that helps operators maximize the benefits of their customized synchronous motor investment. The customization excellence extends to future modification capabilities, allowing motors to be upgraded or reconfigured as operational requirements evolve, providing long-term value and adaptability that justifies the initial investment in customized motor technology.