Modern industrial applications rely heavily on the robust performance of electric motors, with the asynchronous motor standing as one of the most widely used types in manufacturing environments. These motors power everything from conveyor systems to heavy machinery, making their reliable operation critical for maintaining production efficiency. When an asynchronous motor experiences problems, the resulting downtime can significantly impact operational costs and productivity. Understanding how to identify, diagnose, and resolve common issues ensures that maintenance teams can respond quickly and effectively to keep systems running smoothly.

The complexity of asynchronous motor systems means that problems can arise from various sources, including electrical faults, mechanical wear, environmental factors, and improper maintenance practices. Successful troubleshooting requires a systematic approach that combines visual inspection, electrical testing, and performance monitoring. By developing a comprehensive understanding of these diagnostic techniques, maintenance professionals can minimize unexpected failures and extend motor lifespan while optimizing energy efficiency throughout the operational cycle.

Electrical System Diagnostics

Power Supply and Voltage Issues

Voltage-related problems represent some of the most common causes of asynchronous motor malfunction, affecting both performance and longevity. Undervoltage conditions can cause motors to draw excessive current while producing insufficient torque, leading to overheating and premature component failure. Conversely, overvoltage situations can damage insulation systems and create stress on electrical components that weren't designed to handle elevated voltage levels.

Voltage imbalance between phases presents another critical concern that can reduce motor efficiency and create uneven magnetic fields within the stator. Even a small percentage of voltage imbalance can result in significant current imbalance, causing one phase to work harder than others and potentially leading to single-phase operation conditions. Regular voltage monitoring using quality multimeters or power analyzers helps identify these issues before they cause permanent damage to motor windings.

Phase sequence problems can prevent proper motor rotation or cause reverse operation, particularly problematic in applications where directional control is critical. Installing phase sequence indicators and ensuring proper electrical connections during installation prevents many operational issues. Additionally, checking for loose connections, corroded terminals, and damaged cables forms an essential part of electrical diagnostics, as poor connections create resistance that generates heat and voltage drops.

Current and Insulation Testing

Current measurement provides valuable insights into asynchronous motor health, revealing problems that may not be immediately apparent through visual inspection alone. Measuring starting current, running current, and no-load current helps establish baseline performance parameters and identify deviations that indicate developing problems. Excessive starting current often points to mechanical binding, damaged bearings, or electrical faults within the rotor or stator assemblies.

Insulation resistance testing using megohm meters reveals the condition of winding insulation and helps predict potential failure modes before they occur. Low insulation resistance readings indicate moisture contamination, chemical degradation, or physical damage to insulation materials. Regular insulation testing, particularly in harsh environments, enables proactive replacement decisions that prevent catastrophic failures and associated production losses.

Ground fault detection through insulation testing protects both equipment and personnel from dangerous electrical conditions. Motor windings should maintain high resistance to ground under normal operating conditions, with readings below acceptable thresholds indicating immediate attention requirements. Environmental factors such as humidity, temperature fluctuations, and chemical exposure accelerate insulation degradation, making regular testing essential for motors operating in challenging conditions.

Mechanical Component Analysis

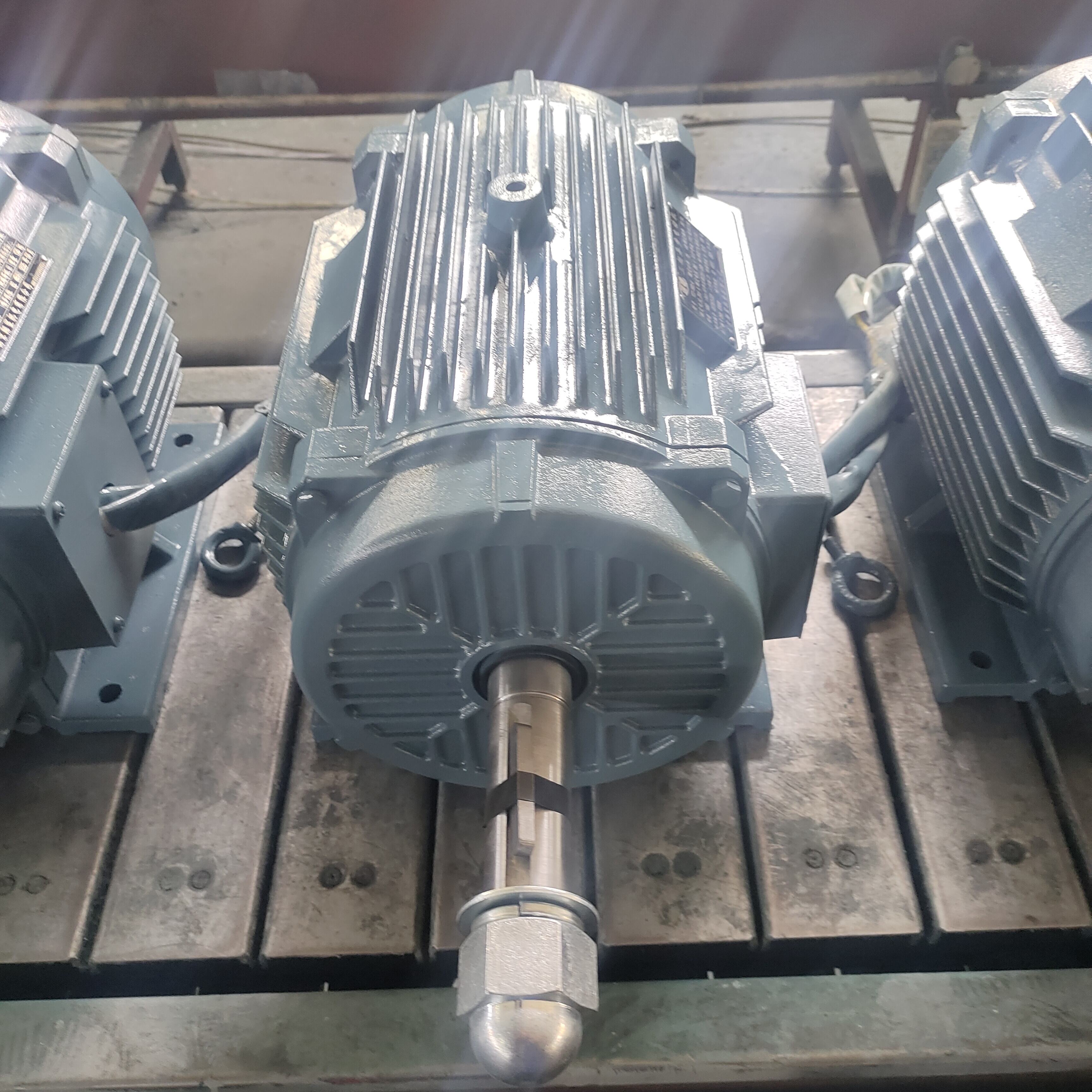

Bearing Assessment and Replacement

Bearing failures account for a significant percentage of asynchronous motor problems, often resulting from inadequate lubrication, contamination, misalignment, or normal wear processes. Early detection of bearing problems through vibration analysis, temperature monitoring, and acoustic inspection enables planned maintenance activities that prevent unexpected breakdowns. Unusual noise patterns, including grinding, squealing, or intermittent rattling sounds, typically indicate bearing deterioration that requires immediate attention.

Proper bearing installation techniques ensure optimal performance and longevity, requiring precise alignment, appropriate interference fits, and correct lubrication procedures. Using bearing pullers and installation tools prevents damage during replacement operations, while maintaining cleanliness throughout the process prevents contamination that can drastically reduce bearing life. Temperature-controlled storage and handling procedures preserve bearing integrity until installation time.

Lubrication scheduling based on manufacturer recommendations and operating conditions prevents both over-lubrication and under-lubrication problems. Excessive grease can cause overheating and seal damage, while insufficient lubrication leads to metal-to-metal contact and rapid wear. Modern synthetic lubricants offer improved performance in extreme temperature and contaminated environments, extending service intervals and reducing maintenance requirements for critical applications.

Alignment and Balance Corrections

Shaft alignment problems create excessive vibration, premature bearing wear, and coupling damage that can propagate throughout connected machinery systems. Laser alignment tools provide precise measurements that enable accurate corrections, reducing operational stresses and extending component life. Angular and parallel misalignment conditions each create specific vibration signatures that trained technicians can identify and correct using proper alignment procedures.

Rotor balance issues manifest as vibration at running speed frequency, often accompanied by bearing temperature increases and unusual noise characteristics. Dynamic balancing procedures using specialized equipment restore proper weight distribution and eliminate vibration sources that stress mechanical components. Temporary balance weights allow field corrections, while permanent solutions may require rotor removal and professional balancing services.

Foundation and mounting problems contribute to alignment and vibration issues that affect asynchronous motor performance. Soft foot conditions, where one or more motor feet don't make solid contact with mounting surfaces, create stress concentrations and alignment problems. Proper foundation design includes adequate mass, vibration isolation, and precise leveling to provide stable motor support throughout the operational envelope.

Thermal Management and Cooling

Temperature Monitoring Systems

Effective temperature management ensures asynchronous motor windings operate within safe thermal limits, preventing insulation damage that leads to costly failures. Built-in temperature sensors, including resistance temperature detectors and thermistats, provide continuous monitoring capabilities that enable automatic protective actions when temperatures exceed preset thresholds. External temperature measurement using infrared thermometers and thermal imaging cameras supplements internal monitoring for comprehensive thermal analysis.

Hot spot identification through thermal imaging reveals uneven temperature distribution that may indicate internal problems such as turn-to-turn faults, poor connections, or inadequate heat dissipation. Regular thermal surveys establish baseline temperature patterns and help identify gradual temperature increases that precede failure events. Comparing temperature readings between similar motors operating under identical conditions helps identify outliers that require further investigation.

Ambient temperature compensation ensures that temperature readings account for environmental variations that affect motor thermal performance. Motors operating in high ambient temperatures require derating to maintain acceptable winding temperatures, while those in extremely cold environments may require special starting procedures or heater installation. Understanding the relationship between ambient conditions and motor thermal performance guides proper application selection and operational procedures.

Cooling System Maintenance

Ventilation system cleanliness directly affects asynchronous motor cooling effectiveness, with blocked air passages causing rapid temperature increases that damage insulation systems. Regular cleaning of cooling fans, air filters, and heat dissipation surfaces maintains optimal airflow and heat transfer characteristics. Accumulated dust, debris, and contaminants reduce cooling efficiency and may create fire hazards in extreme cases.

Fan blade inspection reveals damage or wear that reduces cooling airflow and creates vibration problems. Cracked, bent, or missing fan blades compromise cooling performance and may indicate bearing problems or foreign object impact. Replacement fans must match original specifications to maintain proper cooling characteristics and avoid resonance problems that create noise and vibration issues.

External cooling systems, including forced air circulation and liquid cooling installations, require regular maintenance to ensure continued effectiveness. Checking ductwork for blockages, verifying fan operation, and maintaining cooling fluid levels prevents overheating problems that can quickly damage expensive motor components. Backup cooling systems provide additional protection for critical applications where thermal management is essential for operational continuity.

Performance Optimization Strategies

Efficiency Enhancement Techniques

Energy efficiency improvements in asynchronous motor applications reduce operating costs while supporting environmental sustainability goals. Variable frequency drives enable speed control that matches motor output to actual load requirements, eliminating energy waste associated with fixed-speed operation. Proper drive programming and maintenance ensure optimal performance while protecting motors from harmful electrical conditions such as voltage spikes and harmonic distortion.

Power factor correction using capacitor banks or active correction systems reduces reactive power consumption and may qualify facilities for utility incentives. Poor power factor increases electrical system losses and may result in penalty charges from utility companies. Regular power factor monitoring and correction system maintenance ensures continued benefits while preventing over-correction that can damage electrical equipment.

Load matching ensures that asynchronous motors operate near their rated capacity where efficiency is maximized. Oversized motors operating at light loads consume more energy per unit of work performed, while undersized motors may experience overheating and premature failure. Periodic load analysis using power meters helps identify opportunities for motor replacement or application modifications that improve overall system efficiency.

Predictive Maintenance Implementation

Condition monitoring systems provide continuous data collection that enables predictive maintenance strategies, reducing unexpected failures while optimizing maintenance scheduling. Vibration monitoring, temperature tracking, and electrical signature analysis identify developing problems before they cause operational disruptions. Advanced systems integrate multiple monitoring technologies to provide comprehensive equipment health assessments.

Data trending and analysis reveal gradual changes in motor performance that indicate wear progression or developing faults. Establishing baseline measurements during commissioning provides reference points for future comparisons, while statistical analysis identifies significant deviations that require investigation. Modern monitoring systems use machine learning algorithms to improve diagnostic accuracy and reduce false alarm rates.

Maintenance scheduling based on actual equipment condition rather than arbitrary time intervals optimizes resource utilization and minimizes unnecessary downtime. Condition-based maintenance strategies extend equipment life while reducing spare parts inventory requirements and maintenance labor costs. Integration with computerized maintenance management systems enables automated work order generation and maintenance history tracking for continuous improvement.

FAQ

What causes asynchronous motors to overheat during operation

Overheating in asynchronous motors typically results from inadequate cooling, excessive load conditions, voltage problems, or internal electrical faults. Blocked ventilation, damaged cooling fans, or accumulated debris restricts airflow and reduces heat dissipation capacity. Electrical issues such as voltage imbalance, single-phase operation, or turn-to-turn faults create additional heat generation that exceeds the motor's thermal design limits. Regular maintenance including cleaning, proper ventilation, and electrical system monitoring prevents most overheating problems.

How often should bearing lubrication be performed on industrial motors

Bearing lubrication frequency depends on motor size, operating conditions, and manufacturer recommendations, typically ranging from monthly intervals for high-speed applications to annual servicing for standard industrial motors. Harsh environments with high temperatures, moisture, or contamination require more frequent lubrication to maintain bearing protection. Over-lubrication can cause overheating and seal damage, making it essential to follow manufacturer specifications and use appropriate lubricant quantities during maintenance procedures.

What diagnostic tools are essential for motor troubleshooting

Essential diagnostic tools include multimeters for electrical measurements, insulation testers for winding condition assessment, vibration analyzers for mechanical problem detection, and infrared thermometers for temperature monitoring. Clamp-on ammeters enable current measurement without electrical disconnection, while oscilloscopes help analyze electrical waveforms and identify power quality issues. Advanced facilities benefit from motor circuit analyzers that combine multiple testing functions into integrated diagnostic systems for comprehensive motor evaluation.

When should an asynchronous motor be replaced versus repaired

Motor replacement decisions depend on repair costs compared to new motor prices, availability of replacement parts, and expected remaining service life. Generally, repairs exceeding 60-70% of replacement cost favor new motor installation, particularly for older units where efficiency improvements provide operational savings. Critical applications may justify repair costs that exceed normal economic thresholds to minimize downtime, while non-critical motors operating at low efficiency may warrant replacement even when repair costs are reasonable.