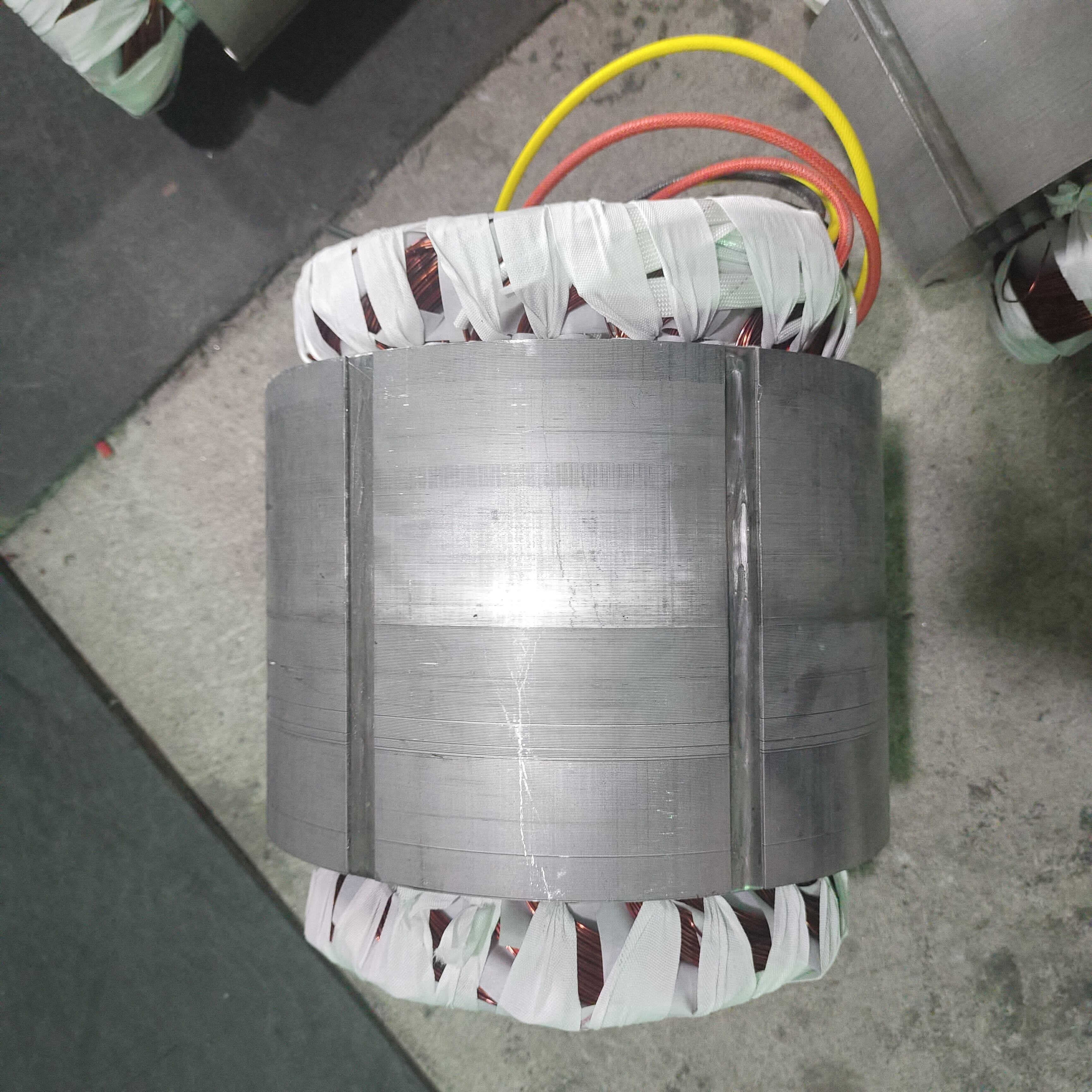

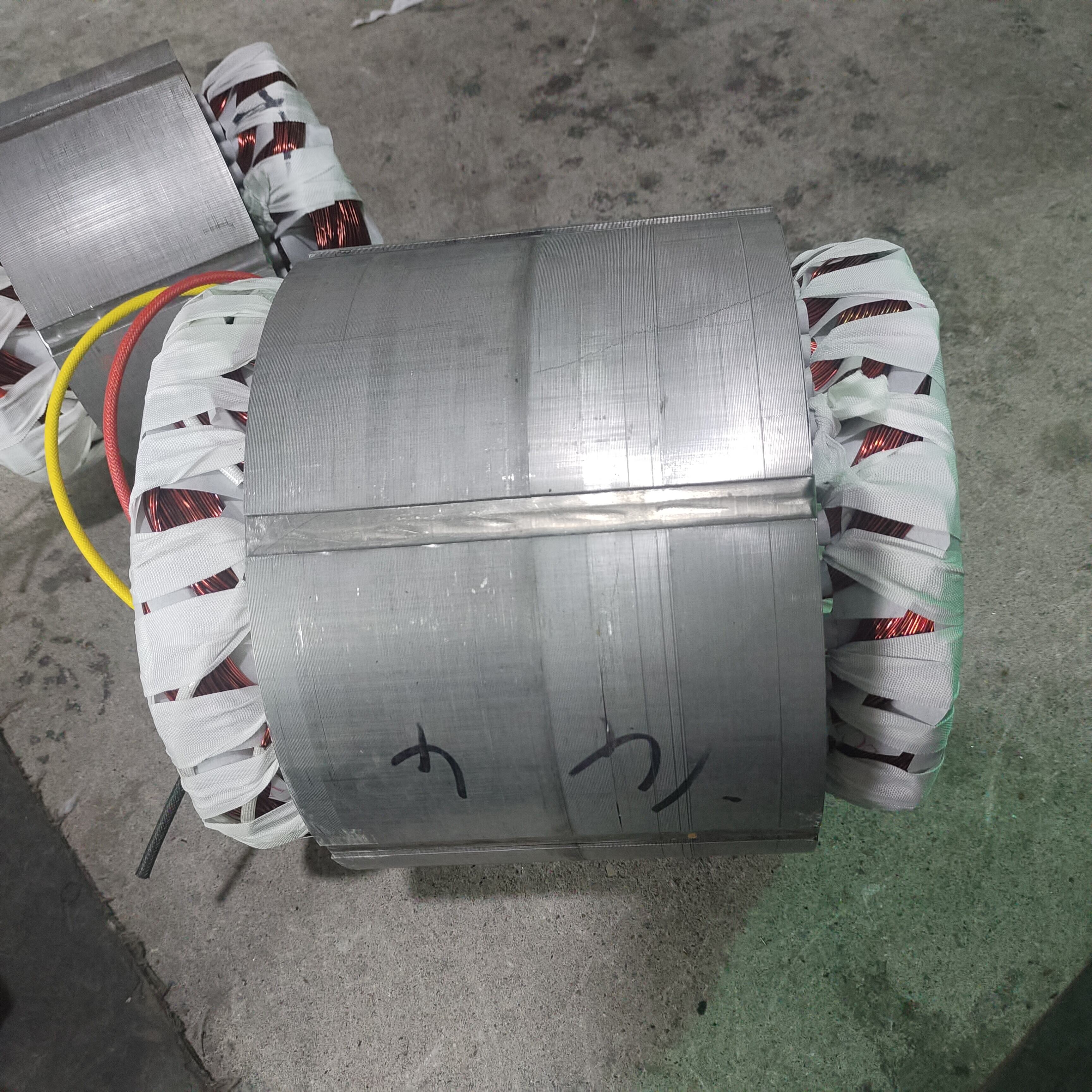

winding in stock

Winding in stock represents a critical component in electrical and mechanical systems, serving as the foundation for electromagnetic devices across numerous industries. This essential element consists of carefully arranged coils of conductive material, typically copper or aluminum wire, wound around a core structure to create specific electrical or magnetic properties. The winding in stock configuration enables efficient energy transfer, signal transmission, and electromagnetic field generation in various applications. These pre-manufactured windings offer significant advantages over custom-built alternatives, providing immediate availability and cost-effective solutions for manufacturers and repair facilities. The technological features of winding in stock include precise conductor spacing, optimized insulation materials, and standardized connection points that ensure reliable performance across different operating conditions. Modern manufacturing processes ensure consistent quality and dimensional accuracy, making these components suitable for high-frequency applications, power distribution systems, and control circuits. The core materials used in winding in stock designs range from ferrite cores for high-frequency applications to laminated steel cores for power transformers, each selected to optimize magnetic permeability and minimize energy losses. Advanced insulation systems protect the conductors from environmental factors, electrical stress, and thermal cycling, extending operational lifespan significantly. Quality control measures during production include electrical testing, dimensional verification, and performance validation to ensure each winding in stock unit meets stringent industry standards. These components find extensive use in transformers, inductors, motors, generators, and various electronic devices where electromagnetic functionality is required. The standardization of winding in stock products facilitates easy integration into existing systems while reducing design complexity and manufacturing lead times for equipment manufacturers worldwide.