winding brands

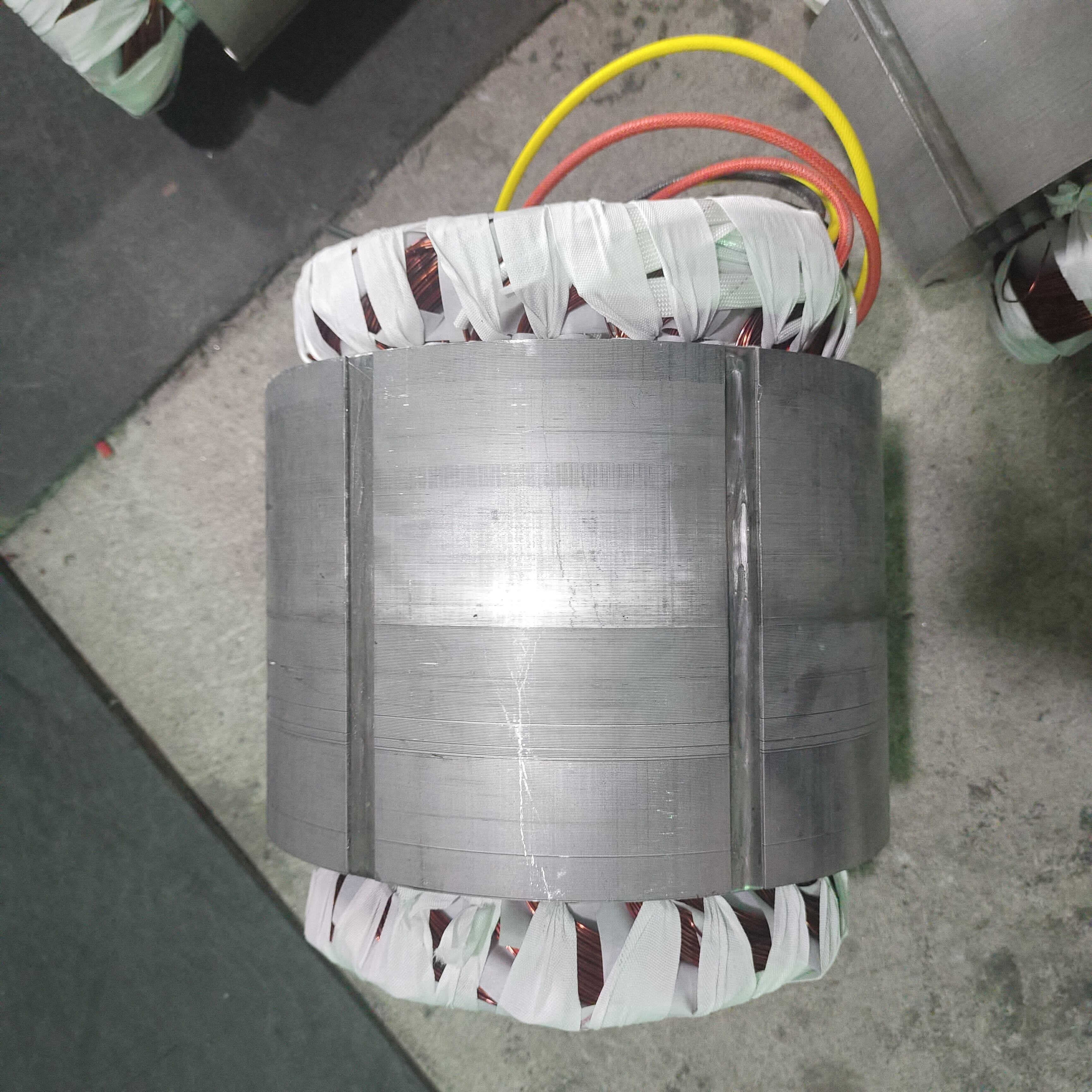

Winding brands represent a sophisticated category of electrical equipment manufacturers specializing in the production of transformers, motors, generators, and inductors. These companies focus on creating precise electromagnetic coil systems that convert electrical energy efficiently across various industrial applications. The primary function of winding brands centers on manufacturing copper or aluminum wire coils that generate magnetic fields for energy transformation, power distribution, and electrical motor operation. Modern winding brands utilize advanced computer-controlled machinery to ensure consistent wire tension, precise layer placement, and optimal insulation between conductors. Their technological features include automated tension control systems that maintain uniform wire spacing throughout the winding process, preventing electrical short circuits and ensuring long-term reliability. Temperature monitoring systems integrated into their equipment detect overheating conditions during operation, automatically adjusting cooling mechanisms to prevent damage. Many winding brands incorporate digital position feedback controls that guarantee accurate wire placement with tolerances measured in micrometers. Advanced insulation materials developed by leading winding brands provide superior electrical isolation while maintaining compact designs. These materials resist moisture, chemicals, and extreme temperatures, extending equipment lifespan significantly. Applications for winding brands span across power generation facilities, automotive manufacturing, renewable energy systems, industrial automation, and consumer electronics. Electric vehicle manufacturers rely heavily on winding brands for motor production, where lightweight yet powerful electromagnetic systems enable efficient transportation. Wind turbine generators require specialized winding configurations that handle variable speed operations while maximizing energy capture from fluctuating wind conditions. Medical equipment manufacturers depend on precision winding brands for MRI machines, where magnetic field uniformity directly affects image quality and patient safety.