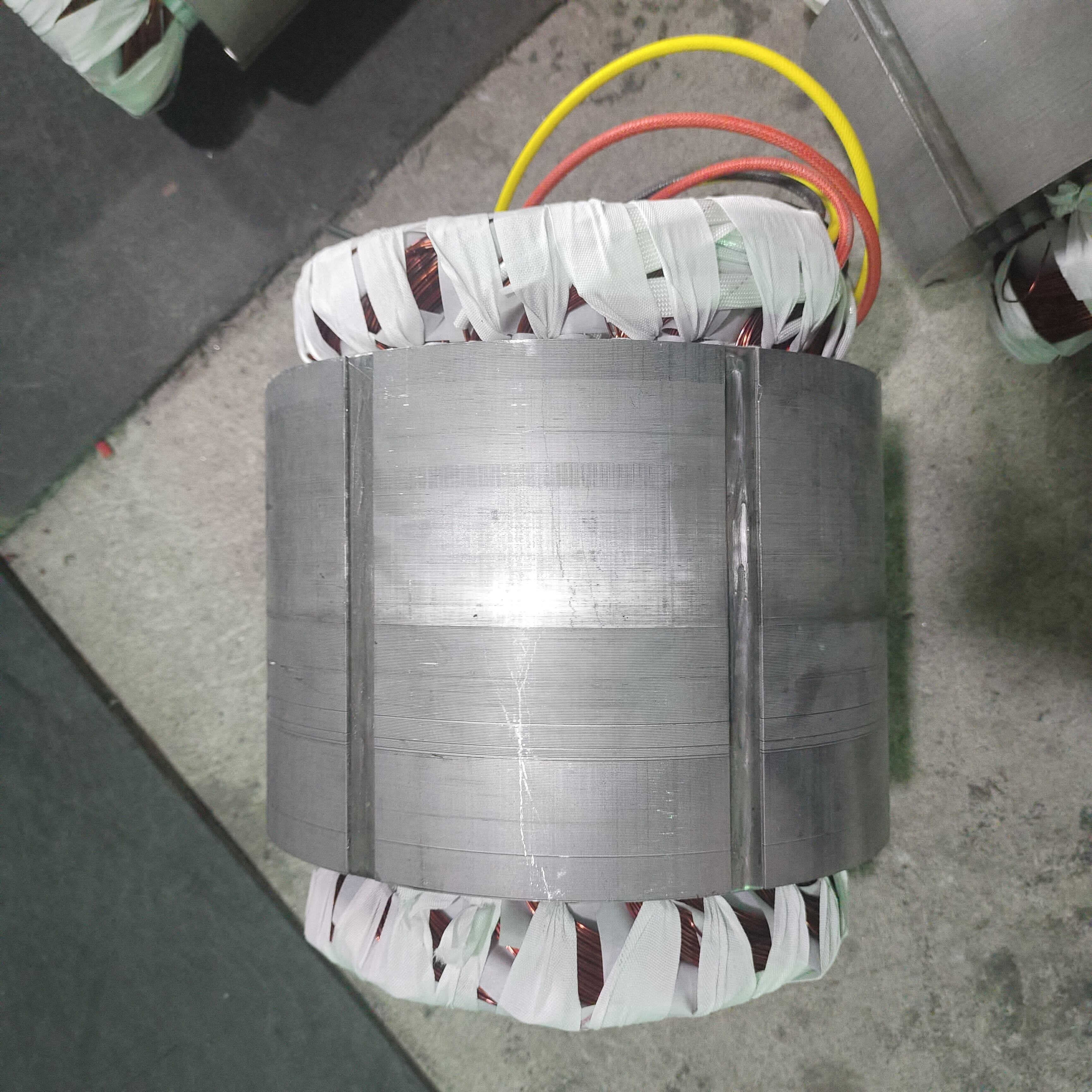

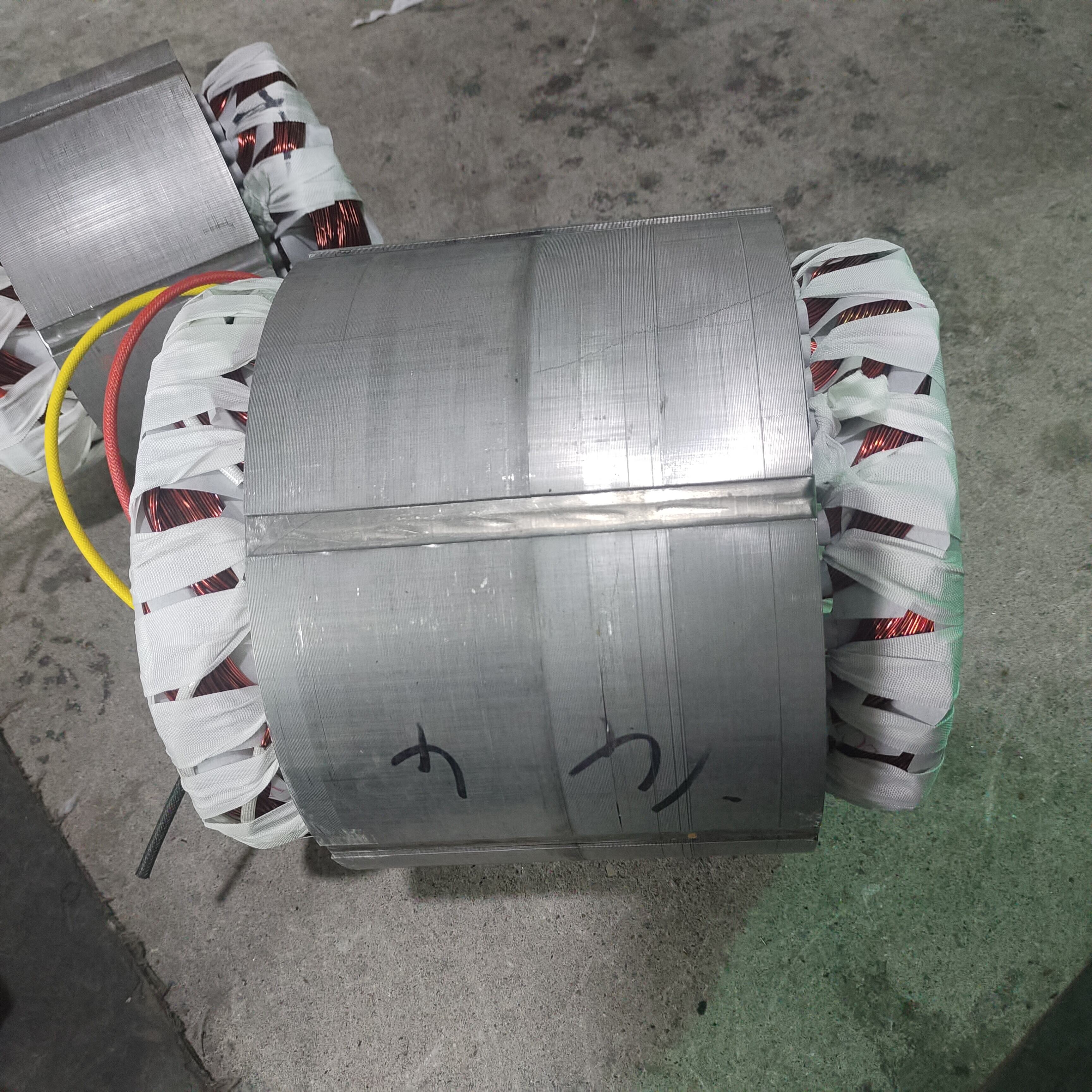

winding suppliers

Winding suppliers represent a crucial segment of the manufacturing industry, specializing in the production and distribution of electromagnetic coils, transformers, motors, and related components. These specialized companies serve as the backbone for numerous industries including automotive, aerospace, electronics, renewable energy, and industrial automation. Professional winding suppliers offer comprehensive solutions that encompass custom coil winding, precision transformer manufacturing, and advanced electromagnetic component development. Their primary functions revolve around creating high-quality wound components that convert electrical energy into mechanical motion or transform voltage levels across various applications. The technological sophistication of modern winding suppliers has evolved significantly, incorporating computer-controlled winding machines, automated quality control systems, and advanced materials science. These facilities typically house state-of-the-art equipment capable of handling diverse wire gauges, from ultra-fine magnet wire to heavy-duty power cables. The precision achieved through automated winding processes ensures consistent performance, reduced manufacturing defects, and enhanced product reliability. Leading winding suppliers invest heavily in research and development, continuously improving their manufacturing techniques and expanding their capability to work with exotic materials such as superconducting wires, high-temperature resistant polymers, and specialized alloys. Their applications span across electric vehicle motors, wind turbine generators, medical device components, telecommunications equipment, and consumer electronics. Quality winding suppliers maintain strict adherence to international standards including ISO 9001, UL certifications, and industry-specific requirements. They provide comprehensive services from initial design consultation and prototyping to full-scale production and after-sales support, making them indispensable partners for original equipment manufacturers worldwide.