Avancerede Fremstillingsmuligheder og Præcisionsingeniørarbejde

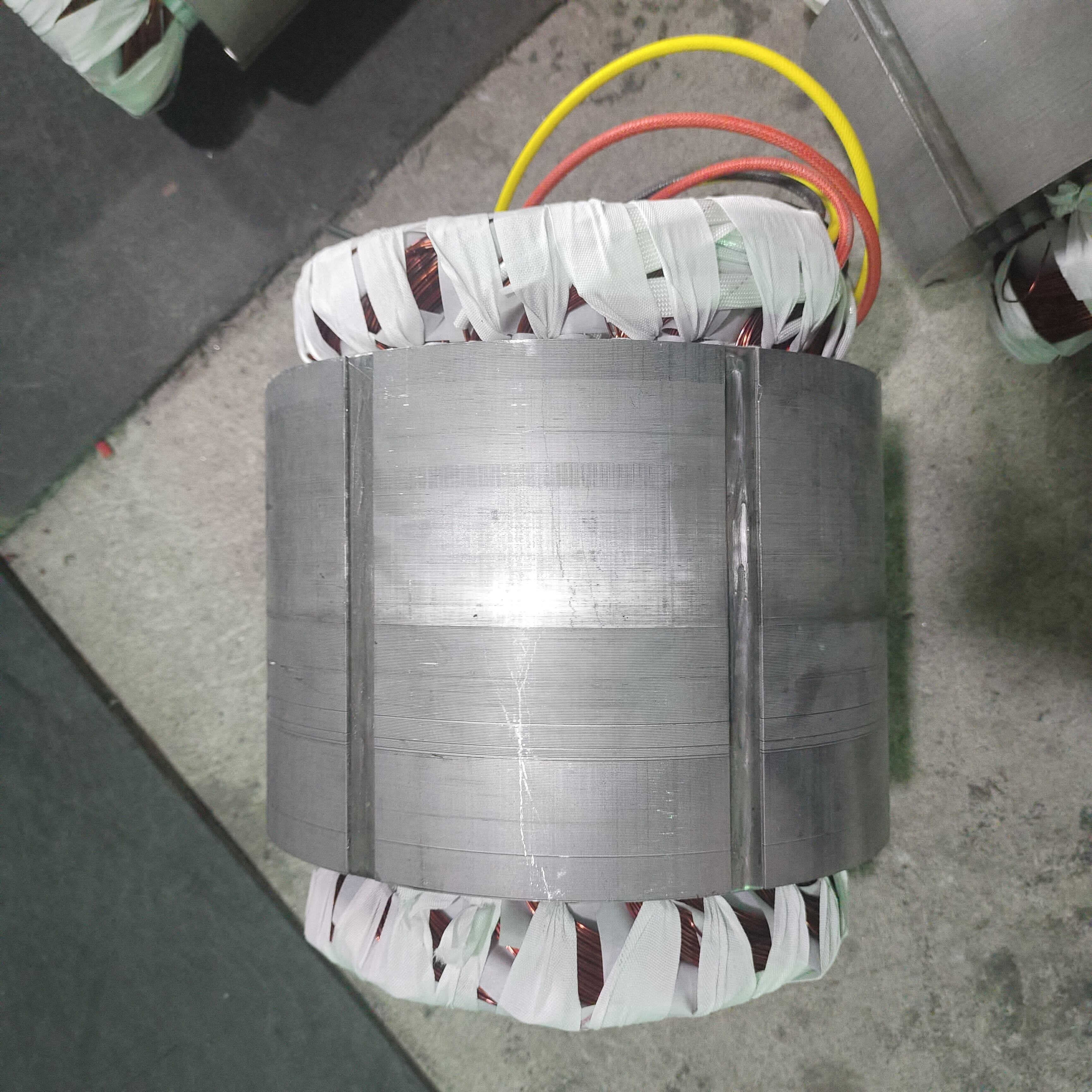

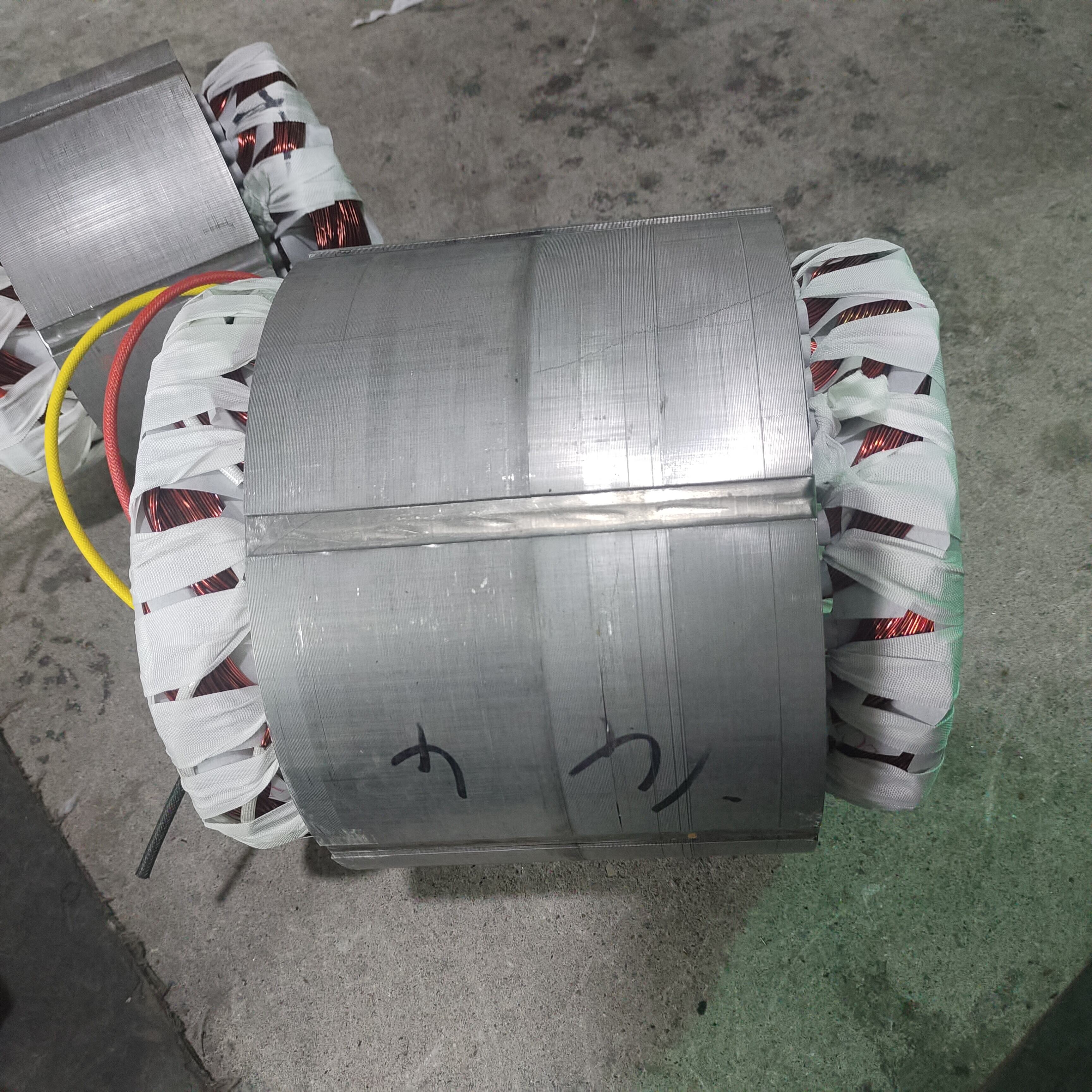

Moderne viklingsleverandører adskiller sig selv gennem sofistikerede produktionsmuligheder, der kombinerer nyeste teknologi med præcisionsingeniørfærdigheder. Faciliteterne omfatter computerstyrede viklemaskiner, der kan opnå tolerancer målt i mikrometer, hvilket sikrer konsekvent ydeevne over tusindvis af enheder. Integrationen af automatiserede køretøjer, robotter til håndtering og kvalitetsovervågning i realtid skaber produktionsmiljøer, hvor menneskelige fejl minimeres, og produktionseffektiviteten maksimeres. Avancerede viklingsleverandører anvender CNC-viklemaskiner med flere akser, som kan håndtere komplekse geometrier, uregelmæssige former og indviklede viklemønstre, som ville være umulige at opnå ved manuelle processer. Deres investeringer i Industri 4.0-teknologier omfatter systemer til prediktiv vedligeholdelse, der forhindrer udstyrsfejl, dataanalyseplatforme, der optimerer produktionsparametre, og digitale tvillingesimulationer, der validerer design før den fysiske produktion påbegyndes. Temperaturregulerede miljøer sikrer konstante materialeegenskaber og viklespændinger, mens specialiserede værktøjer og fastgørelser imødekommer unikke kundekrav uden at kompromittere kvalitetsstandarder. Disse leverandører vedligeholder omfattende materialelagre, herunder forskellige trådstørrelser, isolationstyper, kerne materialer og specialkomponenter, hvilket muliggør hurtig respons på kundens behov samt prototypeudvikling. Laboratorier for kvalitetssikring er udstyret med impedansanalyzere, termiske billedsystemer, vibrationsprøvningsudstyr og accelererede aldringstester, der sikrer omfattende validering af færdige produkter. Kombinationen af dygtige teknikere og avanceret automatisering giver disse leverandører mulighed for at håndtere projekter fra miniature spoler til medicinske apparater, der kræver mikroskopisk præcision, til store industrielle transformatorer, der kræver betydelige effekthåndteringskapaciteter. Denne teknologiske sofistikation resulterer i overlegen produktpræstation, længere levetid og reducerede samlede ejerskabsomkostninger for kunder inden for mange forskellige brancher.