Премиум материали и висока устойчивост на околната среда

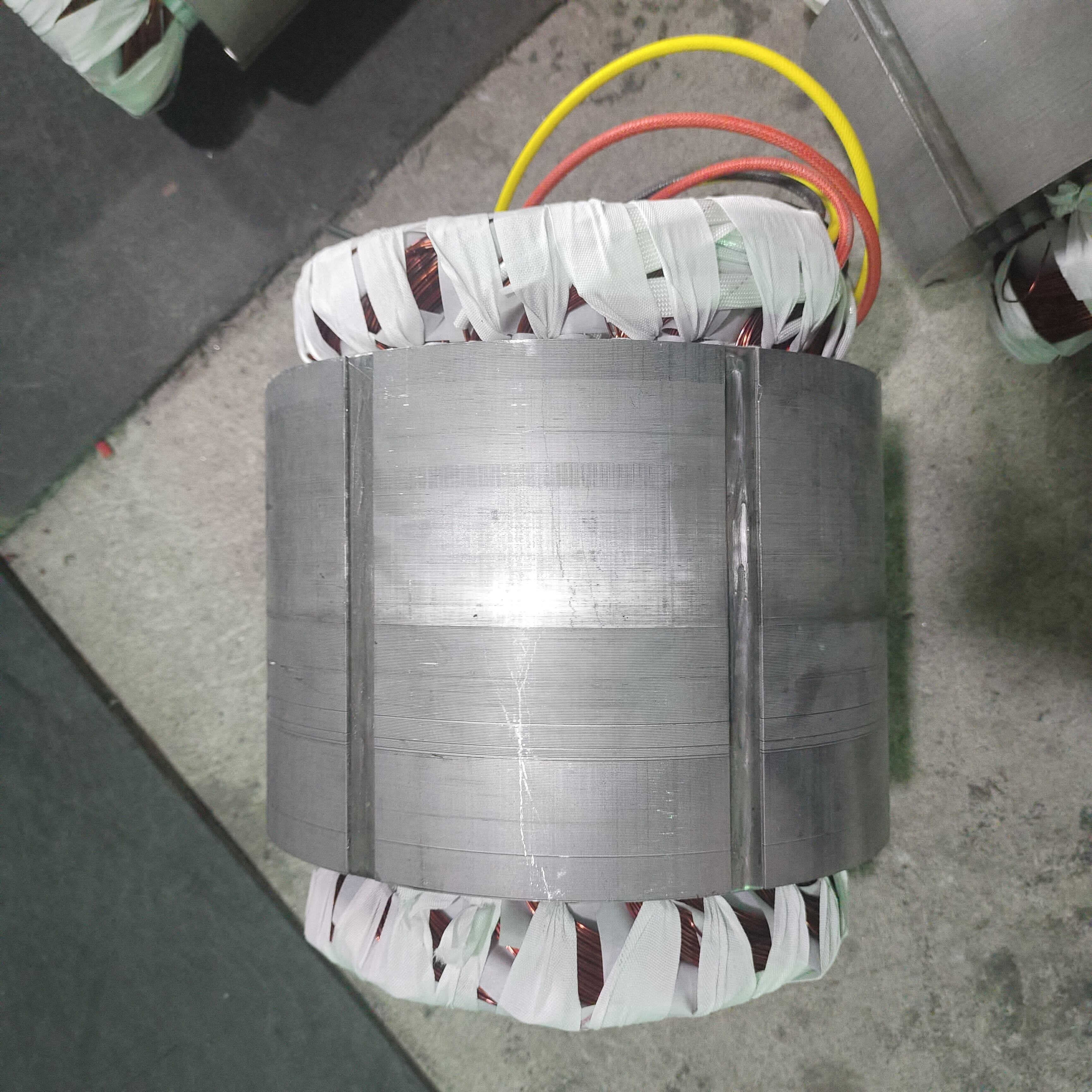

Премиум марките за намотки инвестират значително в напреднали изследвания на материали и тестване за устойчивост към околната среда, за да предлагат продукти, които издържат на изискващи работни условия и запазват постоянна производителност през продължителни периоди на експлоатация. Екипите им по инженерия на материали разработват собствени системи за изолация, които се съпротивляват по-добре срещу проникване на влага, химическо замърсяване и термично разграждане в сравнение с обичайните промишлени материали. Тези специализирани материали преминават през строги тестови протоколи, които имитират десетилетия работа при екстремни условия, осигурявайки надеждна работа в предизвикателни среди. Тестовете за температурни цикли, извършвани от водещите марки за намотки, потвърждават стабилността на материалите в работни диапазони, които надхвърлят типичните изисквания за приложение, осигурявайки резерви за безопасност, които предотвратяват преждевременни повреди. Устойчивостта към корозия, постигната чрез напреднали технологии за покрития, защитава проводящите елементи от щети от околната среда и значително удължава живота на оборудването в сравнение със стандартните материали. Процесът на подбор на материали, прилаган от професионалните марки за намотки, взема предвид не само електрическите и механичните свойства, но и въздействието върху околната среда и възможността за рециклиране, подпомагайки устойчивото производство. Специализирани тестови съоръжения, управлявани от установени марки за намотки, включват климатични камери, солени спрей камери и вибрационни маси, които точно възпроизвеждат реални работни условия с научна прецизност. Тези комплексни програми за тестване идентифицират потенциални видове повреди още преди продуктите да достигнат клиентите, елиминирайки гаранционни искания и осигурявайки последователна производителност. Процедурите за осигуряване на качество, прилагани от авторитетни марки за намотки, включват проверки на входящи материали, тестване по време на производствения процес и окончателни верификационни протоколи, които гарантират, че материалните свойства отговарят на зададените изисквания. Системите за проследяване, поддържани от професионални марки за намотки, отчитат партидните номера на материалите през целия производствен процес, позволявайки бързо идентифициране и отстраняване на евентуални проблеми с качеството. По-висококачествените материали, използвани от водещите марки за намотки, позволяват работа при екстремни температури, висока влажност и корозивни атмосфери, при които стандартните продукти биха се повредили бързо. Официалните сертификати за околната среда, получени от отговорните марки за намотки, демонстрират ангажимента им към намаляване на екологичния след, като едновременно предлагат по-висока производителност и по-голяма издръжливост.