winding in voorraad

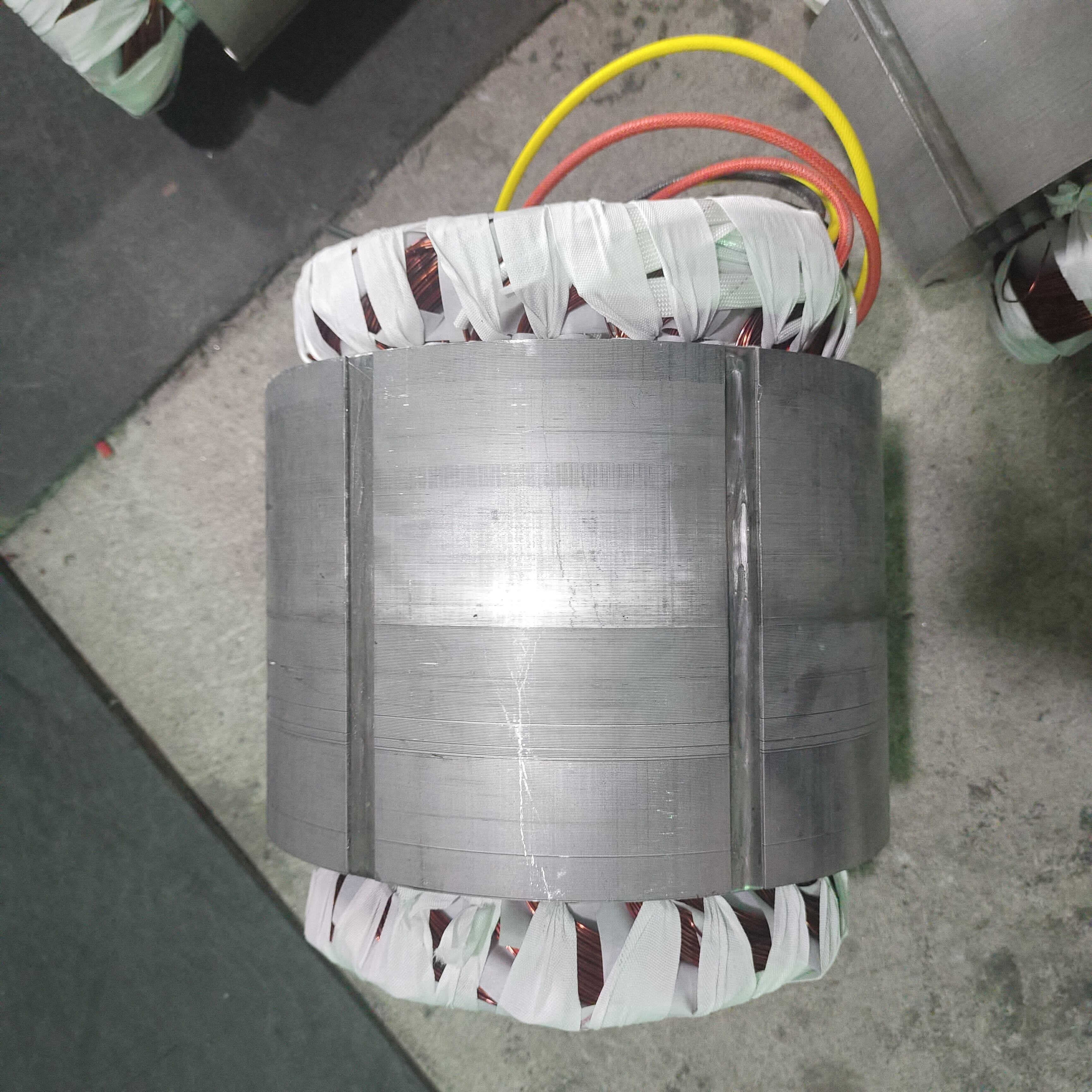

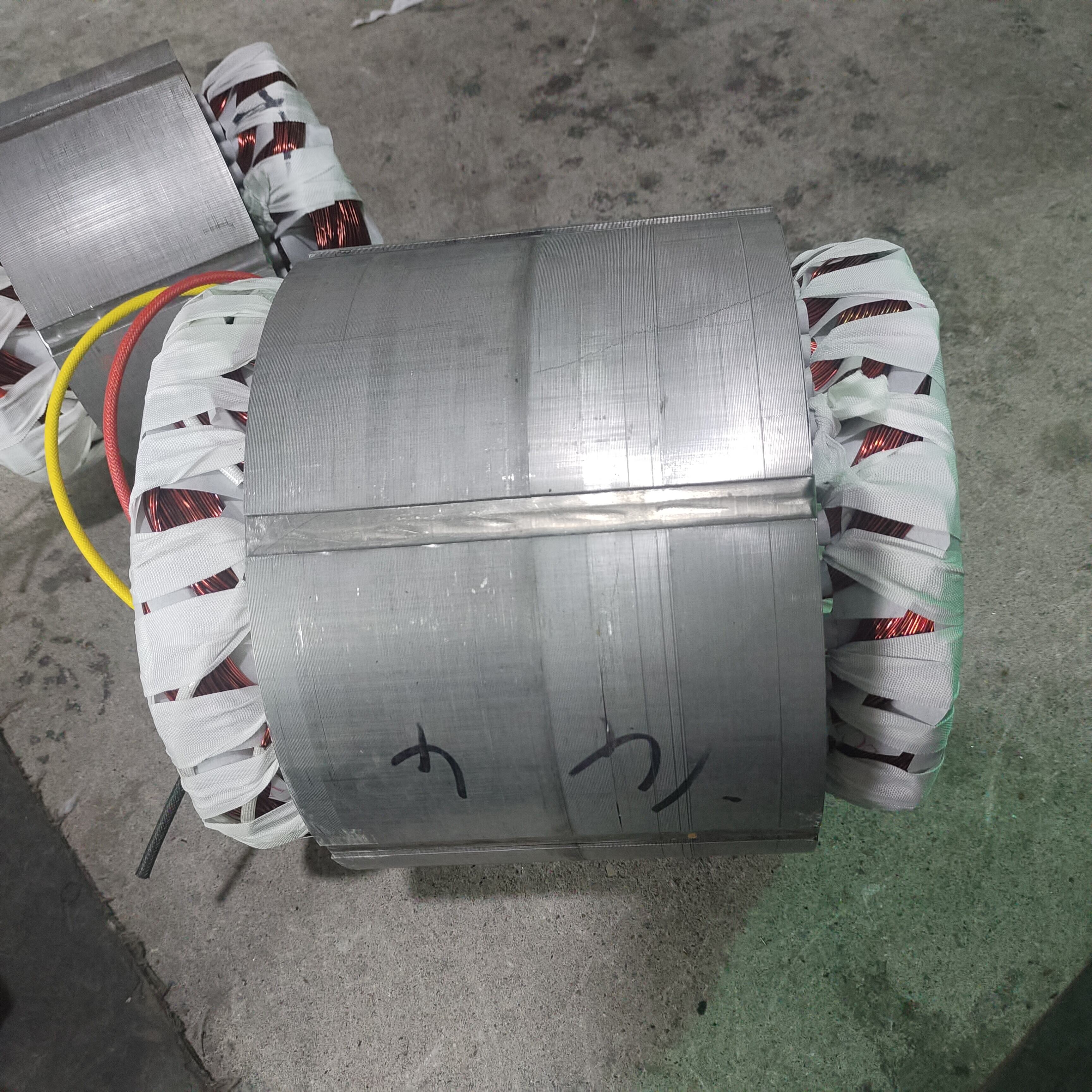

Winding in voorraad verteenwoordig 'n kritieke komponent in elektriese en meganiese stelsels, wat as die fondament vir elektromagnetiese toestelle oor verskeie nywerhede dien. Hierdie essensiële element bestaan uit noukeurig gerangskikte spoelvormige geleidende materiaal, gewoonlik koper- of aluminiumdraad, wat om 'n kernstruktuur gewikkel is om spesifieke elektriese of magnetiese eienskappe te skep. Die winding in voorraad-konfigurasie maak doeltreffende energiedoorgif, seinoordrag en die opwekking van elektromagnetiese velde in verskeie toepassings moontlik. Hierdie voorvervaardigde windinge bied beduidende voordele bo pasgemaakte alternatiewe, deur onmiddellike beskikbaarheid en koste-effektiewe oplossings aan vervaardigers en herstellingfasiliteite te bied. Die tegnologiese kenmerke van winding in voorraad sluit in presiese geleierafstande, geoptimaliseerde isolasiemateriaal en gestandaardiseerde aansluitpunte wat betroubare werkverrigting onder verskillende bedryfsomstandighede verseker. Moderne vervaardigingsprosesse waarborg konsekwente gehalte en dimensionele akkuraatheid, wat hierdie komponente geskik maak vir hoëfrekwensietoepassings, kragverspreidingstelsels en beheerskringloop. Die kernmateriaal wat in winding in voorraad-ontwerpe gebruik word, wissel van ferrietkerne vir hoëfrekwensietoepassings tot gelamineerde staalkerne vir kragtransformators, elk gekies om magnetiese deurlaatbaarheid te optimaliseer en energieverliese tot 'n minimum te beperk. Gevorderde isolasie-stelsels beskerm die geleiers teen omgewingsfaktore, elektriese spanning en termiese siklusse, wat die bedryfswenskap aansienlik verleng. Gehaltebeheermaatreëls tydens produksie sluit elektriese toetsing, dimensionele verifikasie en prestasievalidasie in om te verseker dat elke winding in voorraad-eenheid voldoen aan stringente nywerheidsnorme. Hierdie komponente vind wydverspreide gebruik in transformators, induktors, motore, generators en verskeie elektroniese toestelle waar elektromagnetiese funksionaliteit vereis word. Die standaardisering van winding in voorraad-produkte vergemaklik maklike integrasie in bestaande stelsels terwyl dit ontwerpkompleksiteit en vervaardigingsvoortyd vir toestelvervaardigers wêreldwyd verminder.