rotor suppliers

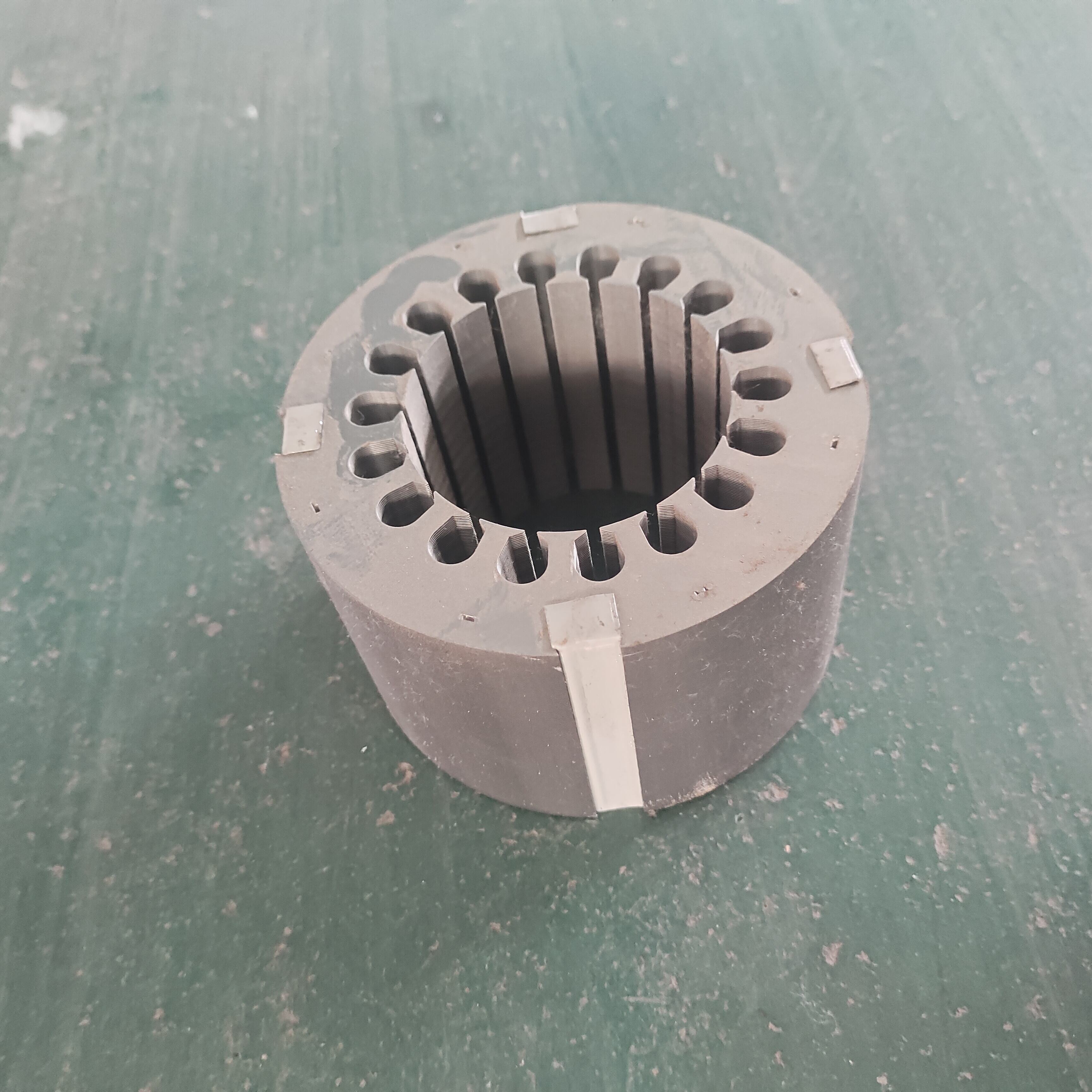

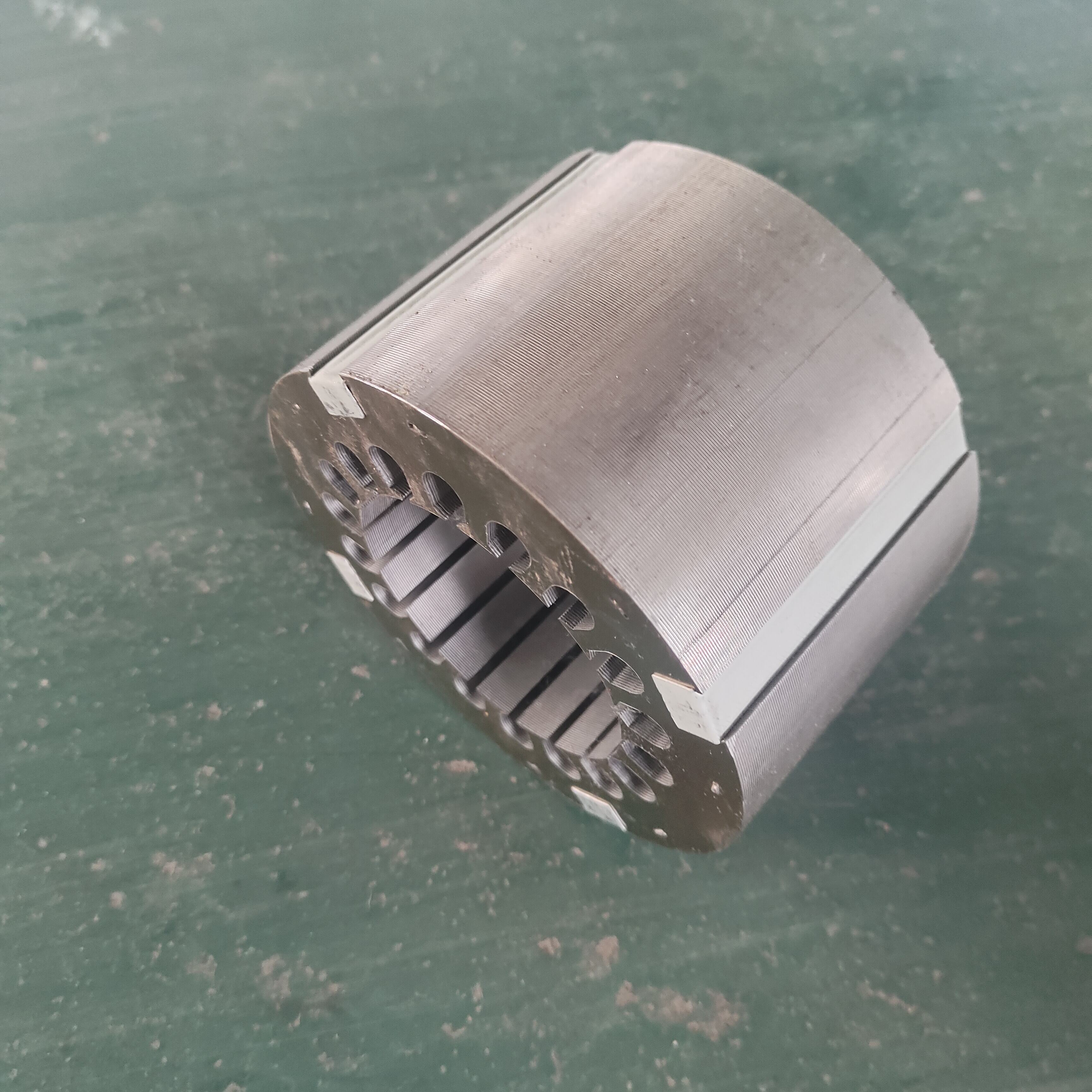

Rotor suppliers play a crucial role in the modern industrial landscape by providing essential rotating components that power countless machines and systems across various sectors. These specialized manufacturers focus on designing, producing, and distributing rotors that serve as the heart of electric motors, generators, turbines, and other rotating machinery. The primary function of rotor suppliers extends beyond simple manufacturing, encompassing comprehensive engineering solutions that include custom design services, precision machining, balancing operations, and quality assurance testing. Leading rotor suppliers utilize advanced manufacturing technologies such as computer-controlled machining centers, automated winding systems, and sophisticated balancing equipment to ensure their products meet stringent performance standards. These companies typically offer a diverse range of rotor types, including squirrel cage rotors for induction motors, wound rotors for slip ring motors, permanent magnet rotors for synchronous machines, and specialized rotors for high-speed applications. The technological features of modern rotor suppliers include state-of-the-art material selection processes, utilizing high-grade electrical steels, copper alloys, and advanced insulation materials to optimize electromagnetic performance and thermal management. Many rotor suppliers have invested heavily in research and development facilities where they continuously innovate to improve rotor efficiency, reduce noise levels, and enhance durability under extreme operating conditions. The applications for rotor suppliers span numerous industries, from automotive and aerospace to renewable energy and industrial automation. In the automotive sector, rotor suppliers provide components for electric vehicle motors, hybrid powertrains, and traditional alternators and starters. The renewable energy industry relies heavily on rotor suppliers for wind turbine generators, hydroelectric turbines, and solar tracking systems. Industrial applications include pumps, compressors, conveyor systems, and manufacturing equipment where reliable rotating machinery is essential for operational success.