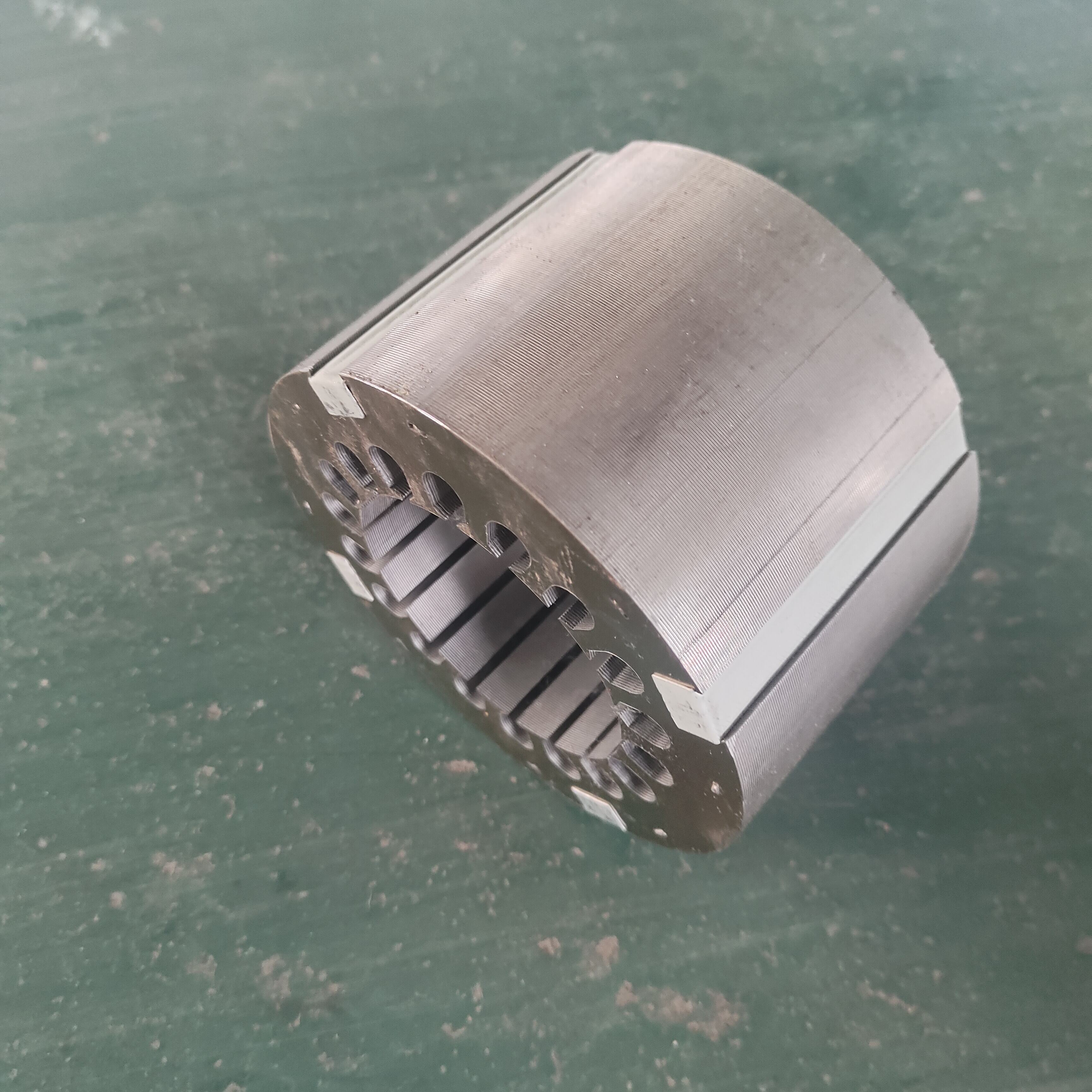

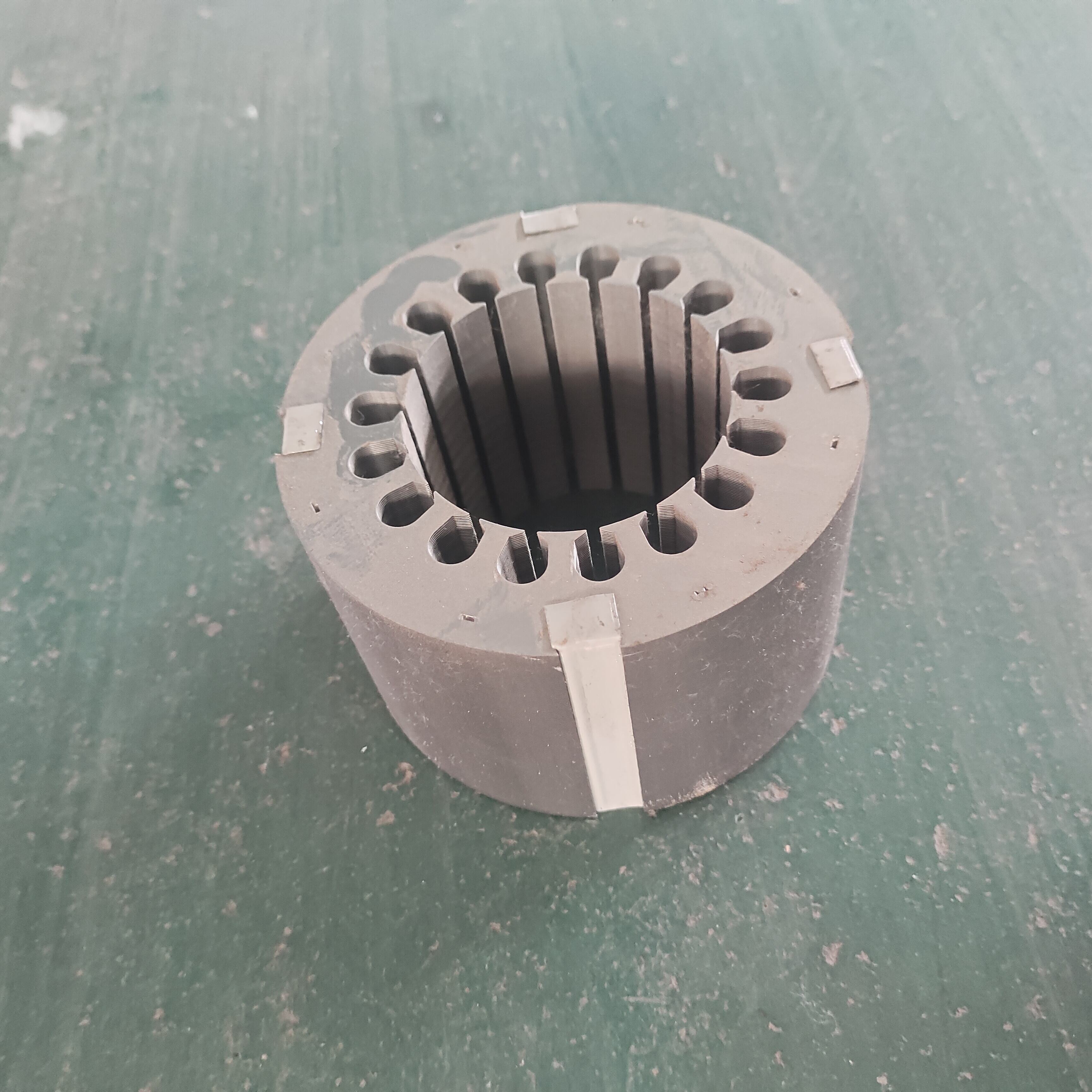

rotor brands

Rotor brands represent cutting-edge solutions in rotating machinery technology, delivering exceptional performance across diverse industrial applications. These specialized manufacturers focus on developing high-precision rotors that serve as critical components in motors, generators, compressors, and turbomachinery systems. Leading rotor brands distinguish themselves through innovative engineering approaches that optimize magnetic field distribution, minimize vibration, and maximize energy efficiency. The primary function of modern rotor brands involves creating rotating assemblies that convert electrical energy into mechanical motion or vice versa, depending on the application requirements. Advanced rotor brands incorporate sophisticated materials science, utilizing high-grade steel alloys, permanent magnets, and composite materials to achieve superior strength-to-weight ratios. Technological features of premium rotor brands include computer-aided design optimization, precision balancing techniques, and advanced coating systems that enhance corrosion resistance and thermal management. These rotor brands leverage finite element analysis to predict stress distribution patterns and optimize magnetic flux paths for maximum performance efficiency. Contemporary rotor brands serve multiple sectors including automotive, aerospace, renewable energy, industrial automation, and HVAC systems. Electric vehicle manufacturers rely on rotor brands to deliver lightweight, high-torque solutions that extend battery life and improve acceleration characteristics. Wind energy applications benefit from rotor brands that withstand harsh environmental conditions while maintaining consistent power generation. Industrial facilities utilize rotor brands in pumps, fans, and conveyor systems where reliability and longevity are paramount. Marine applications depend on rotor brands for propulsion systems and auxiliary equipment that must operate reliably in saltwater environments. The evolution of rotor brands continues advancing through smart manufacturing techniques, predictive maintenance capabilities, and integration with Internet of Things technologies for real-time performance monitoring.