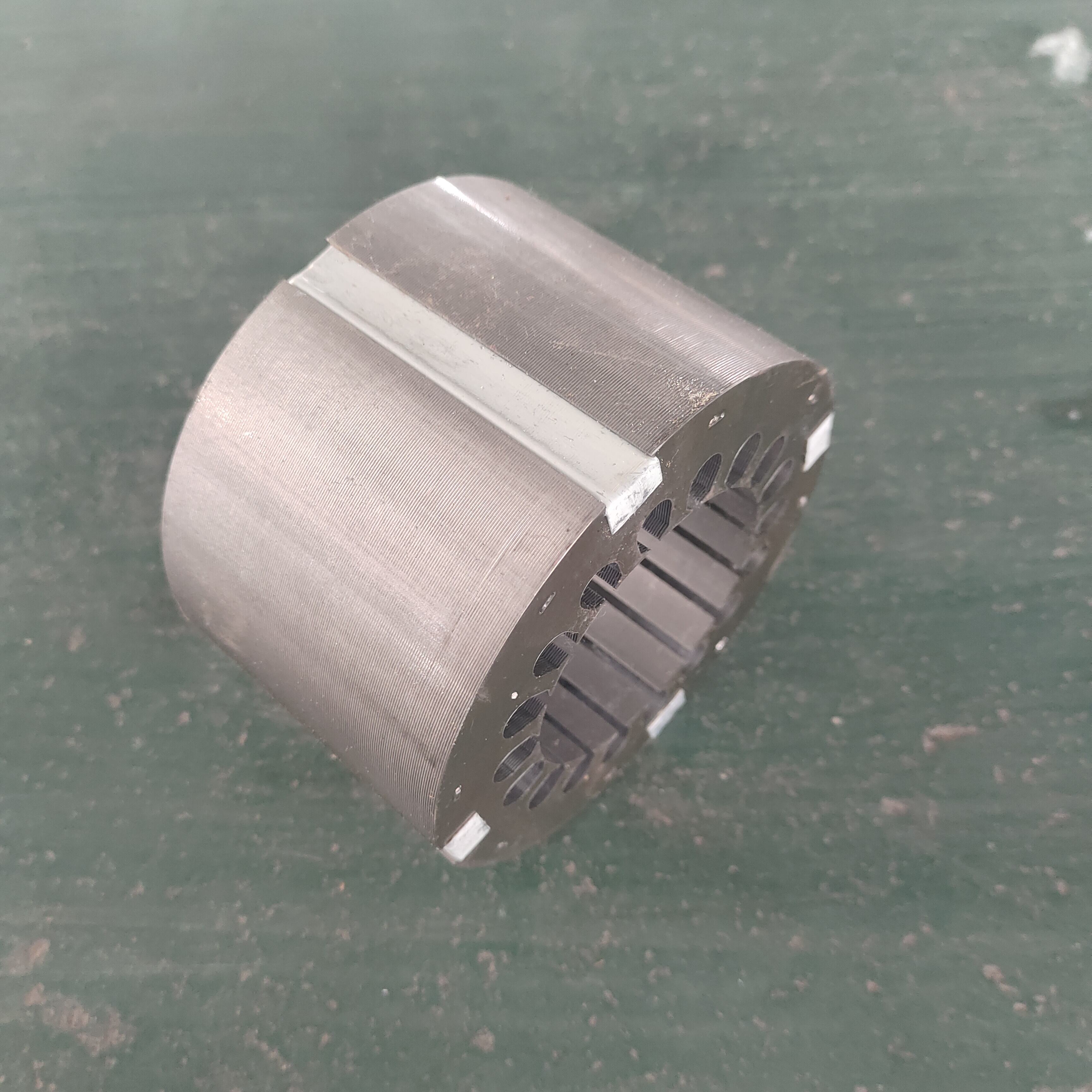

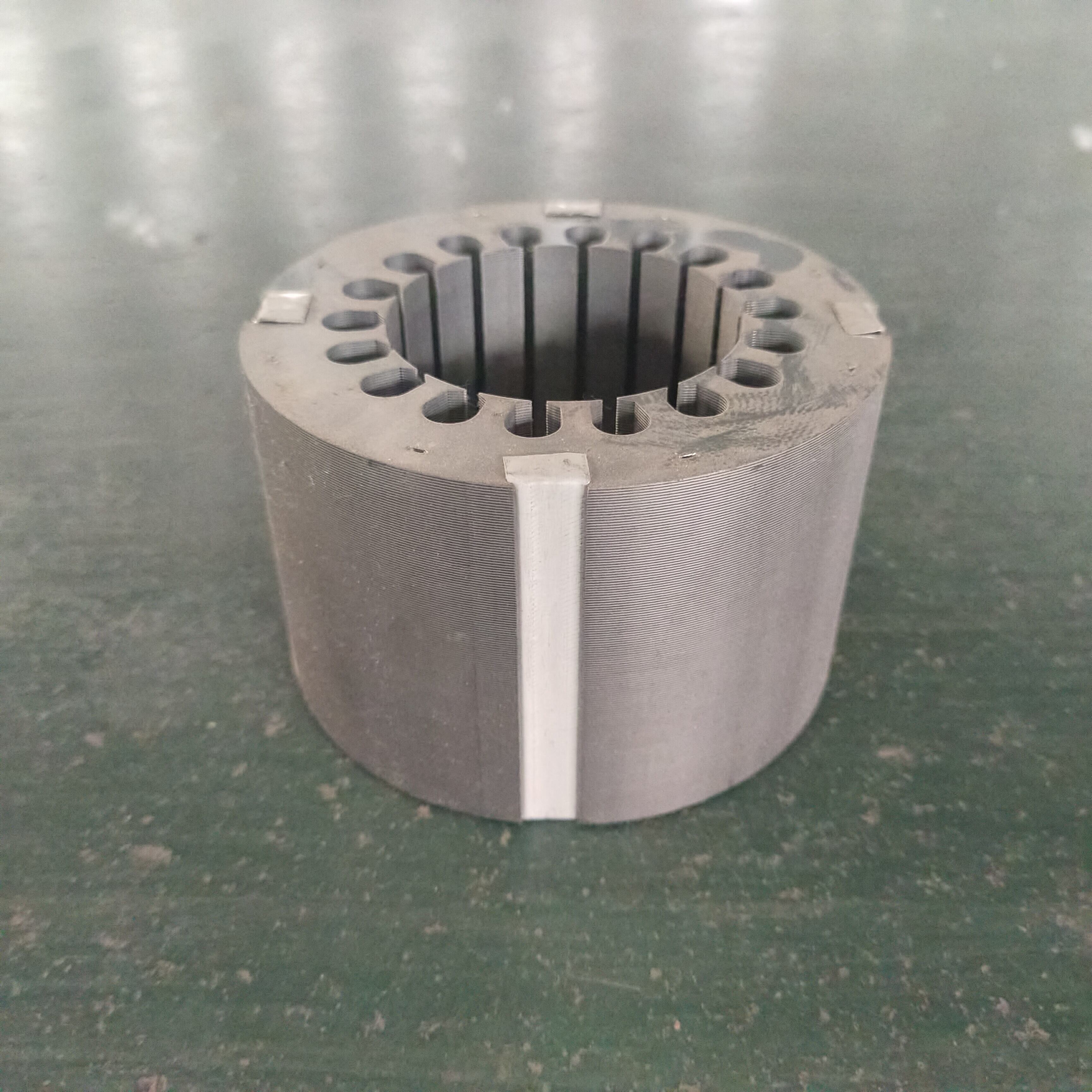

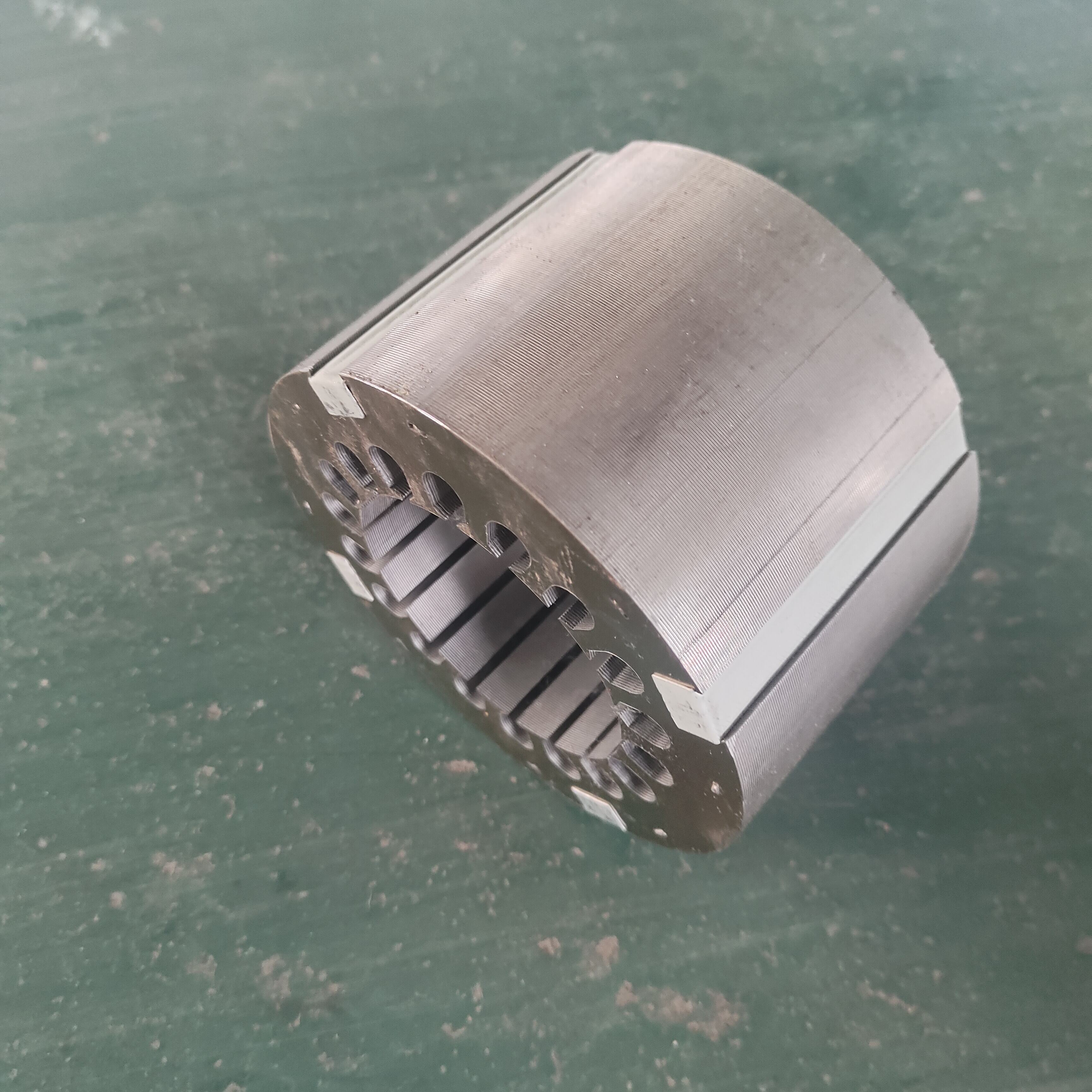

china rotor manufacturers

China rotor manufacturers have established themselves as global leaders in the production of high-quality rotary components for diverse industrial applications. These manufacturers specialize in designing, engineering, and producing rotors for electric motors, turbines, compressors, pumps, and various rotating machinery systems. The primary function of these components involves converting electrical energy into mechanical motion or facilitating fluid movement through rotational mechanisms. China rotor manufacturers utilize advanced manufacturing processes including precision machining, electromagnetic induction heating, dynamic balancing, and computer-controlled quality assurance systems. Their technological capabilities encompass sophisticated material science applications, incorporating high-grade steel alloys, rare earth magnets, and specialized coatings that enhance performance durability. Modern production facilities employ state-of-the-art CNC machining centers, automated assembly lines, and comprehensive testing equipment to ensure dimensional accuracy and operational reliability. The manufacturing process integrates lean production methodologies with stringent quality control protocols, enabling consistent output of precision-engineered rotors. Applications span across automotive industries, aerospace systems, renewable energy sectors, industrial automation, HVAC systems, and marine propulsion technologies. China rotor manufacturers serve original equipment manufacturers (OEMs), aftermarket suppliers, and custom engineering projects worldwide. Their production capabilities range from small-scale specialized rotors for precision instruments to large industrial rotors for power generation equipment. The integration of research and development initiatives allows these manufacturers to continuously innovate and adapt to evolving market demands. Quality certifications including ISO standards, automotive specifications, and international safety regulations demonstrate their commitment to excellence and global market compliance.