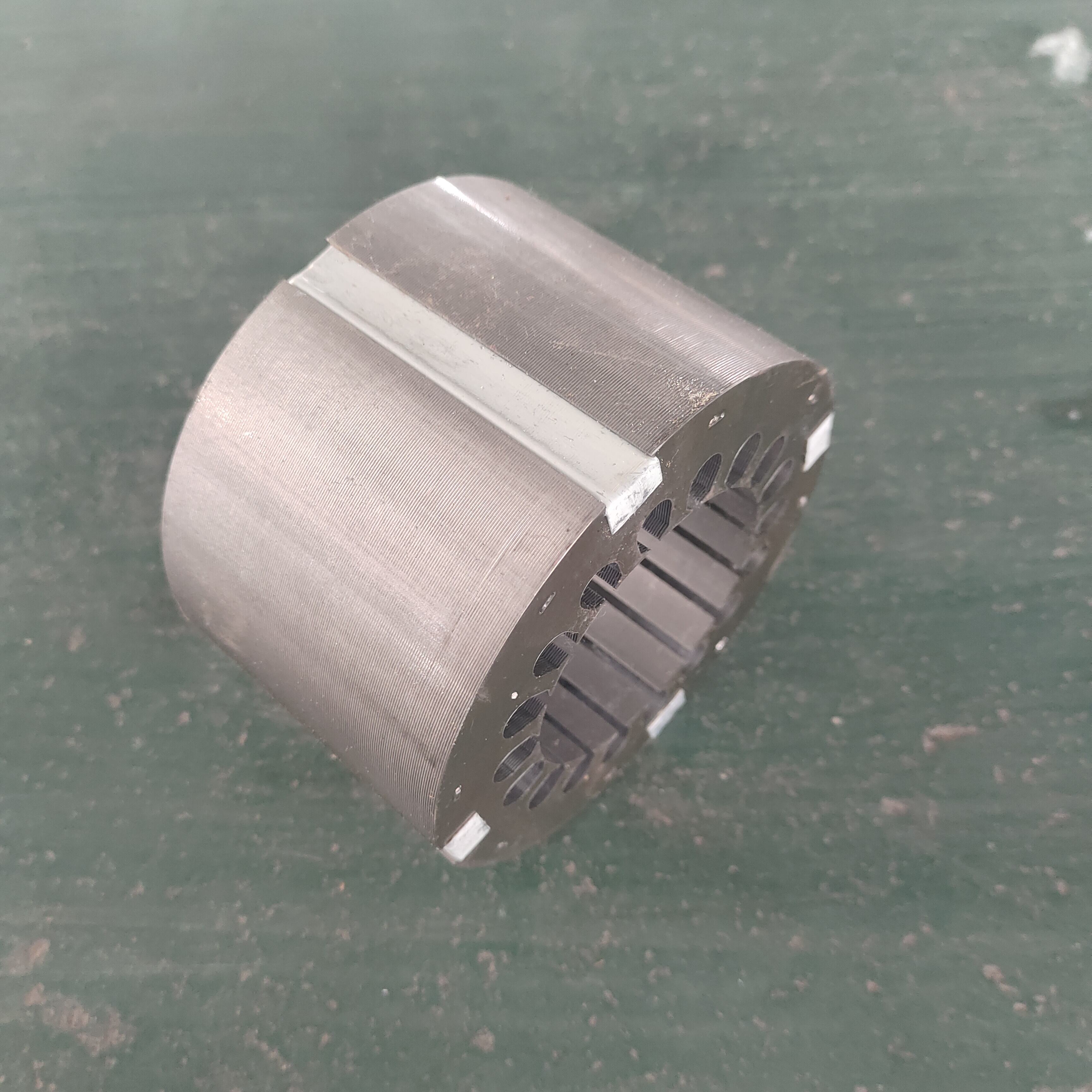

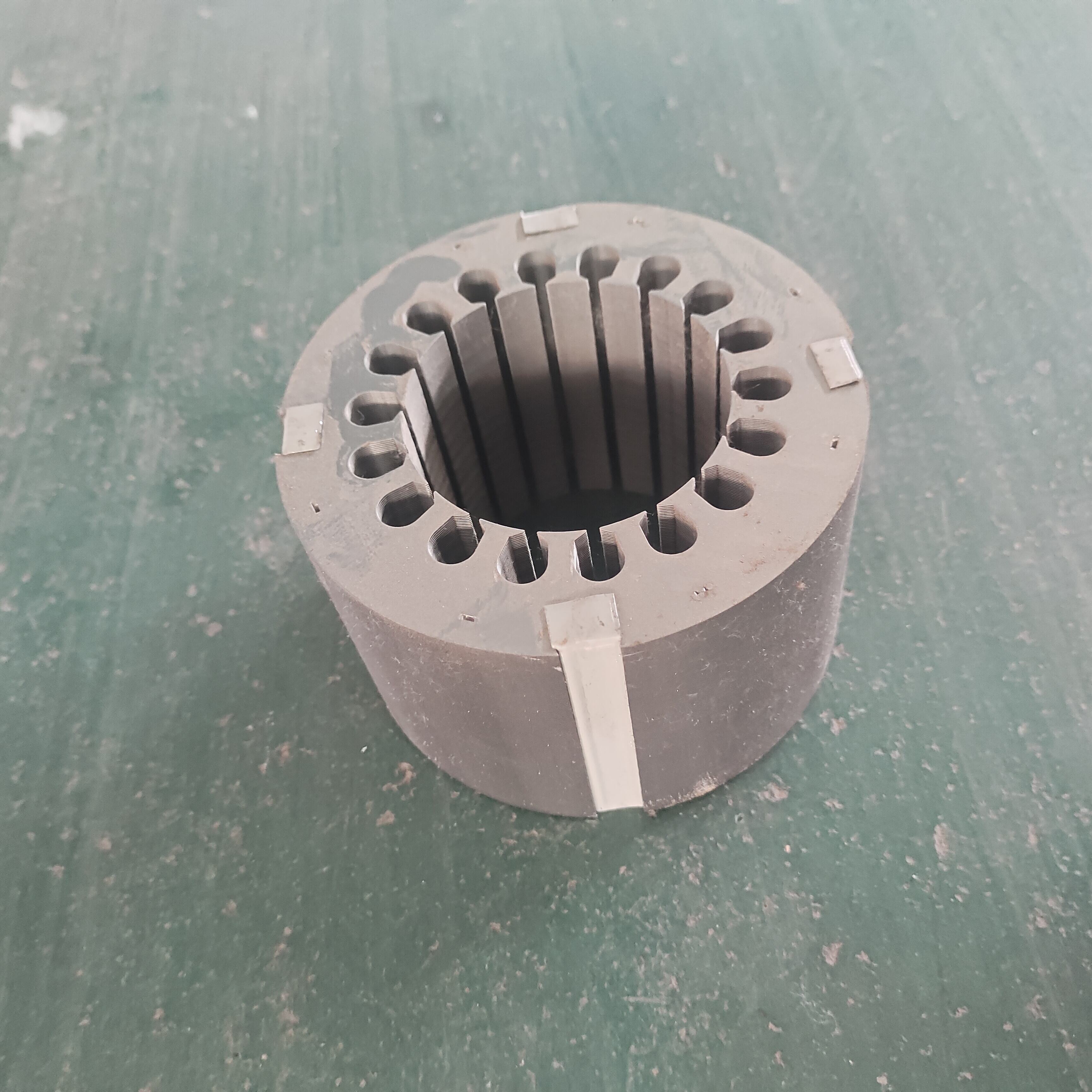

rotor quotation

A rotor quotation represents a comprehensive pricing proposal for rotating machinery components that serve as the heart of various industrial systems. The rotor quotation encompasses detailed specifications, pricing structures, and technical parameters for rotating elements used in motors, generators, turbines, compressors, and other mechanical equipment. This document provides essential information about rotor dimensions, materials, manufacturing processes, delivery timelines, and associated costs. The main functions of a rotor quotation include facilitating accurate budget planning, enabling technical comparisons between suppliers, and establishing clear procurement guidelines for maintenance teams and project managers. The rotor quotation typically includes detailed engineering drawings, material certifications, performance specifications, and quality assurance protocols. Technological features highlighted in modern rotor quotations encompass advanced materials like high-strength steel alloys, precision machining capabilities, dynamic balancing specifications, and surface treatment options. These quotations often detail magnetic properties, electrical characteristics, thermal resistance ratings, and operational speed ranges. Applications for rotor quotation services span across multiple industries including power generation, manufacturing, aerospace, automotive, and renewable energy sectors. Electric motor manufacturers rely on rotor quotations to source replacement parts and upgrade existing systems. Wind turbine operators utilize these quotations for maintenance planning and performance optimization. Industrial facilities depend on accurate rotor quotations to minimize downtime and ensure operational continuity. The rotor quotation process involves detailed technical analysis, material selection, manufacturing assessment, and cost calculation. Professional suppliers provide comprehensive rotor quotations that include installation guidance, warranty terms, and post-delivery support services. These documents serve as contractual foundations for procurement decisions and help organizations maintain competitive operational costs while ensuring reliability and performance standards.