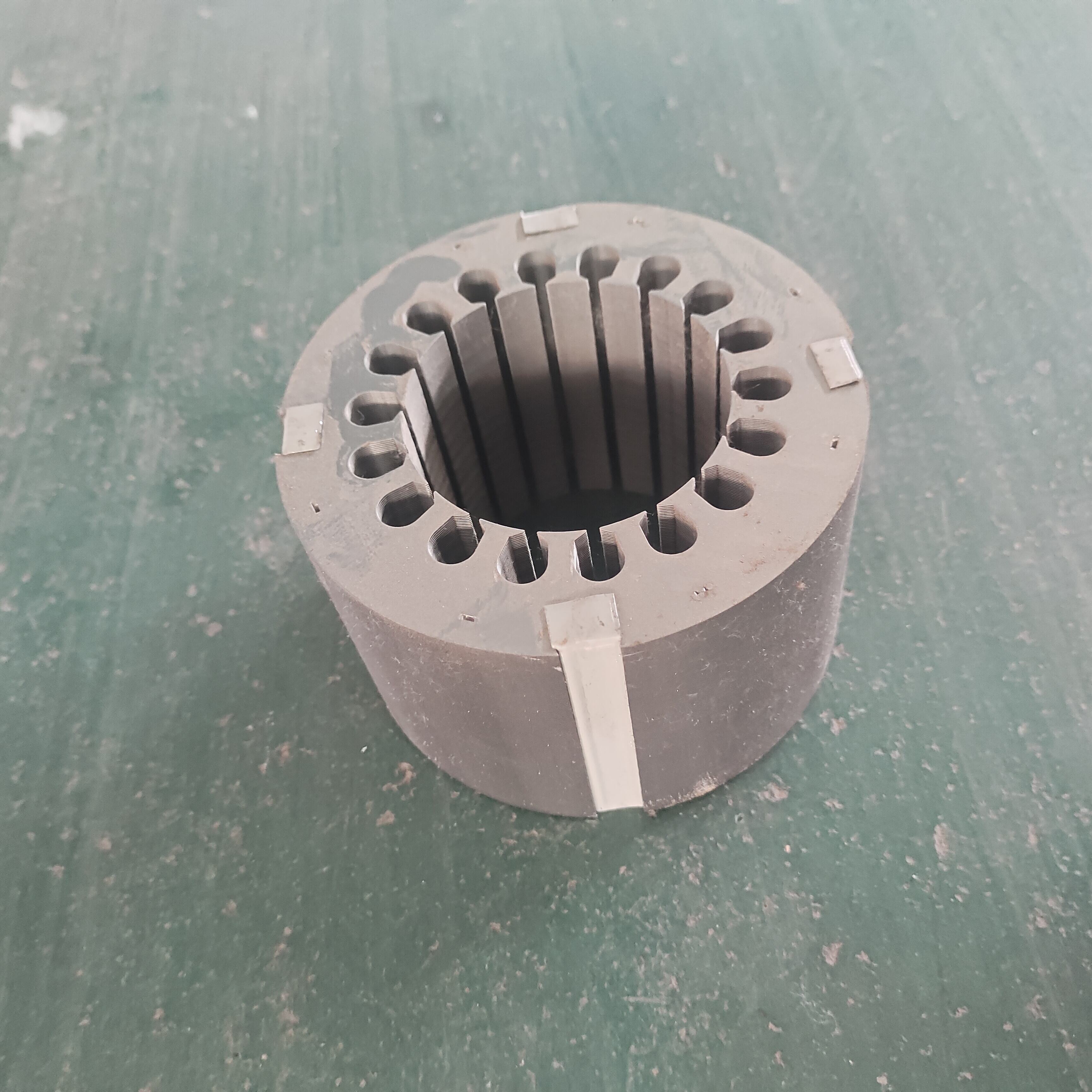

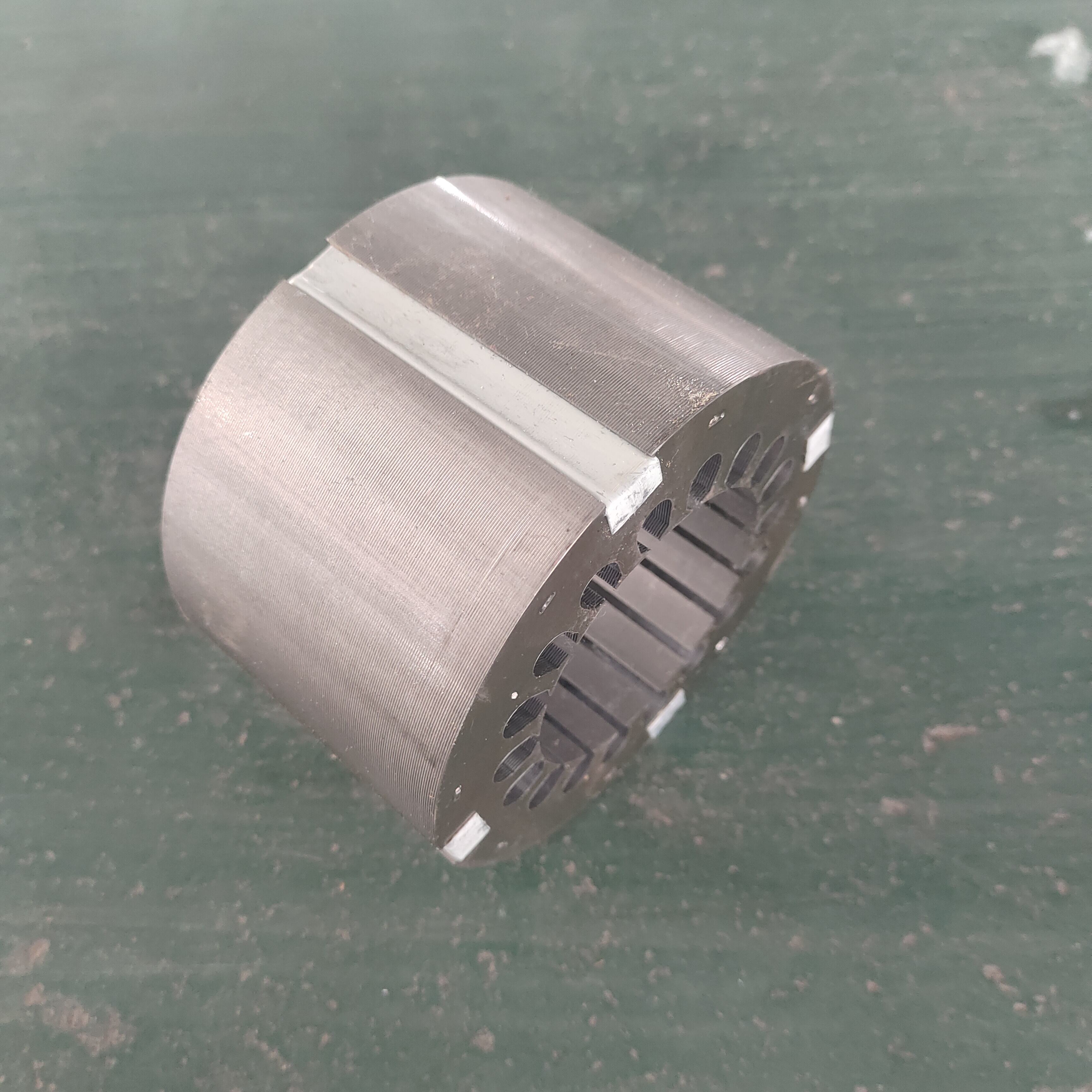

rotor made in china

The rotor made in China represents a pinnacle of precision engineering and manufacturing excellence that has transformed the global machinery industry. These sophisticated rotating components serve as the heart of countless mechanical systems, converting electrical energy into mechanical motion with remarkable efficiency. Chinese manufacturers have invested heavily in advanced production technologies, enabling them to produce rotors that meet international quality standards while maintaining competitive pricing. The rotor made in China incorporates cutting-edge materials science, utilizing high-grade steel alloys, rare earth magnets, and specialized coatings that enhance performance and longevity. Modern manufacturing facilities employ computer-controlled machining centers, precision balancing equipment, and stringent quality control protocols to ensure each rotor meets exact specifications. The technological features of the rotor made in China include optimized magnetic field distribution, reduced cogging torque, enhanced thermal management, and improved dynamic balancing characteristics. These rotors find extensive applications across diverse industries including automotive manufacturing, renewable energy systems, industrial automation, aerospace applications, and consumer electronics. The automotive sector particularly benefits from Chinese-manufactured rotors in electric vehicle motors, hybrid powertrains, and various auxiliary systems. Wind turbine generators worldwide increasingly rely on rotors made in China for their reliability and cost-effectiveness. Industrial applications encompass everything from conveyor systems and pumps to compressors and machine tools. The versatility of the rotor made in China extends to specialized applications such as medical equipment, robotics, and precision instruments. Chinese manufacturers have developed comprehensive production capabilities that span from small precision rotors for electronic devices to massive industrial rotors for power generation equipment. The integration of Industry 4.0 principles in Chinese manufacturing facilities ensures consistent quality, traceability, and continuous improvement in rotor production processes.