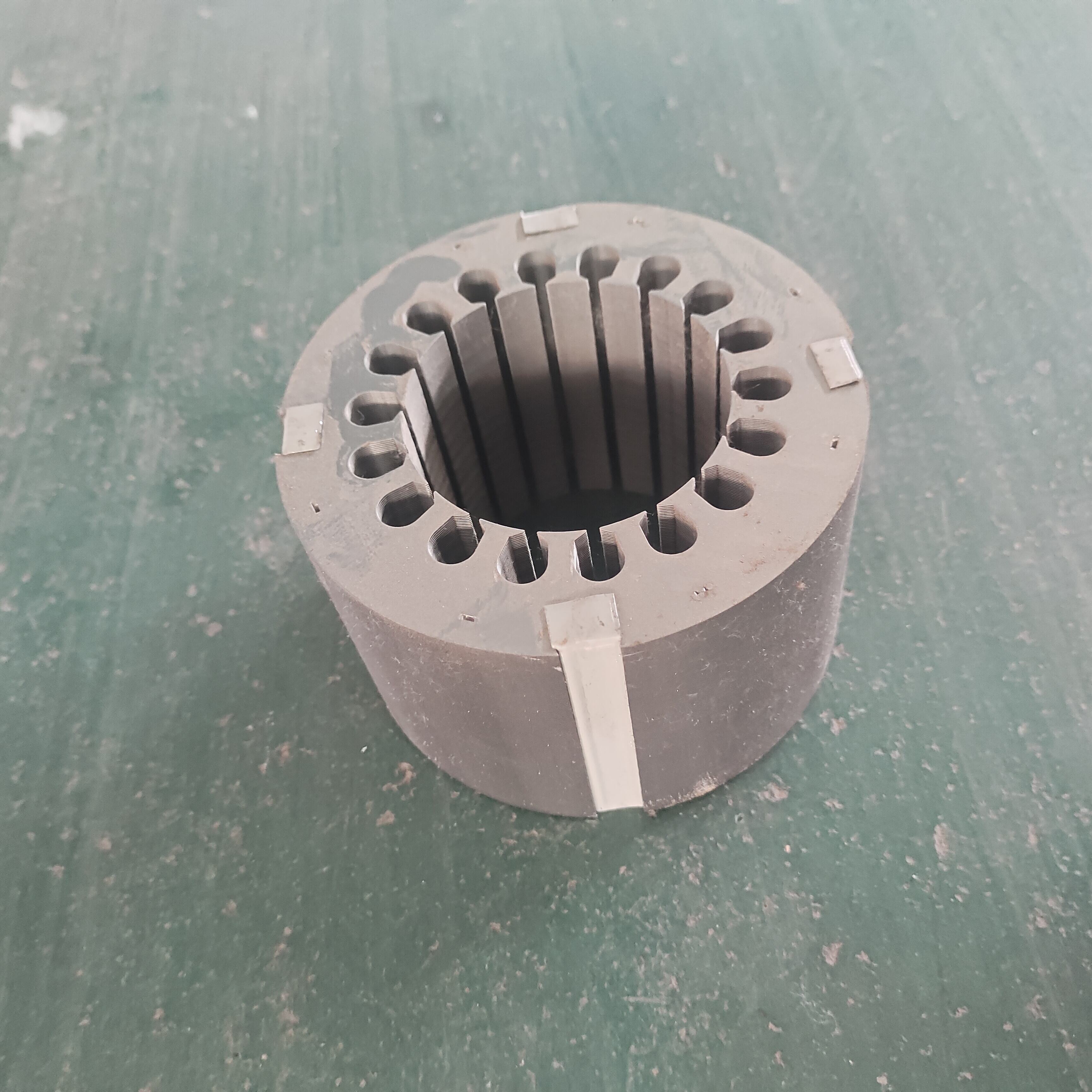

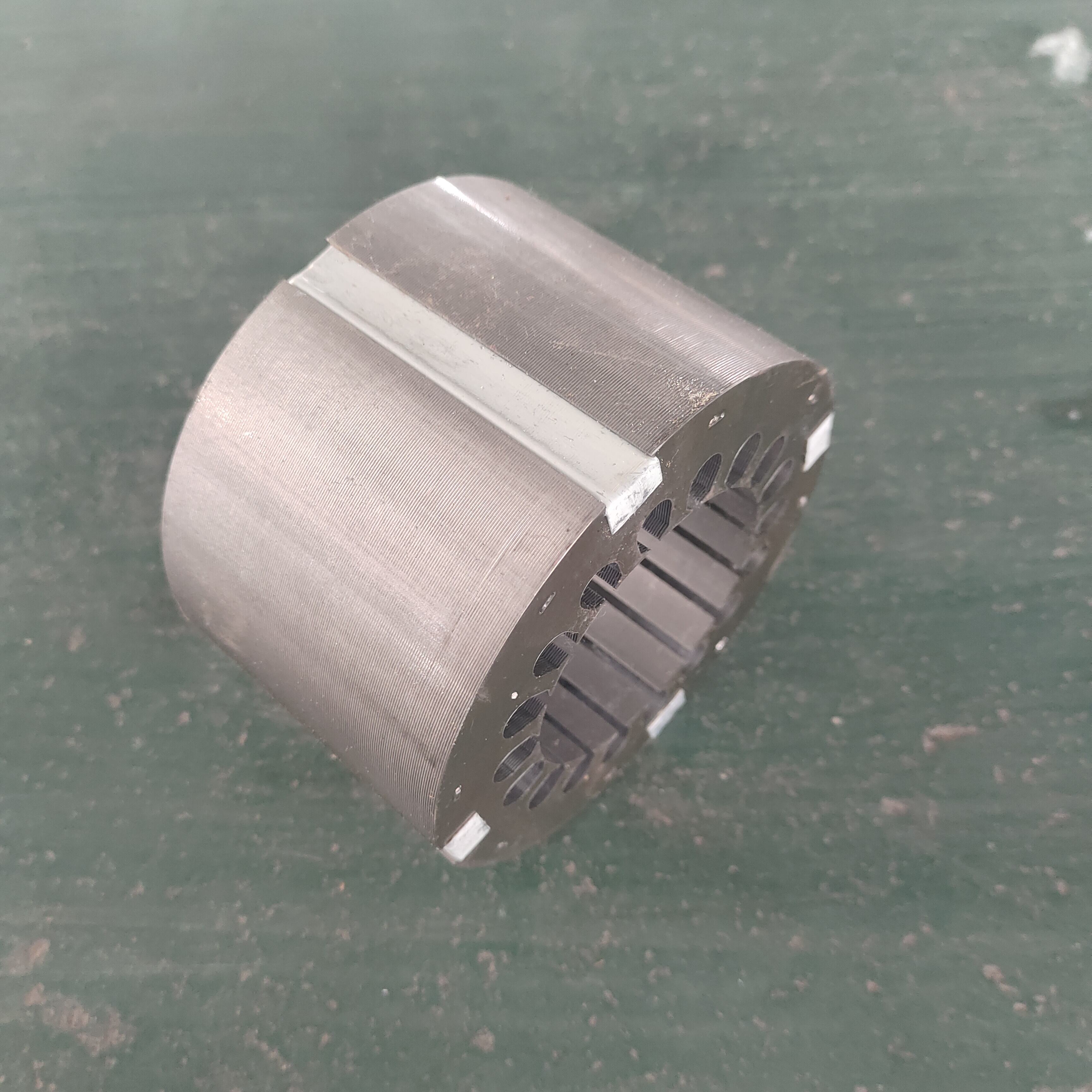

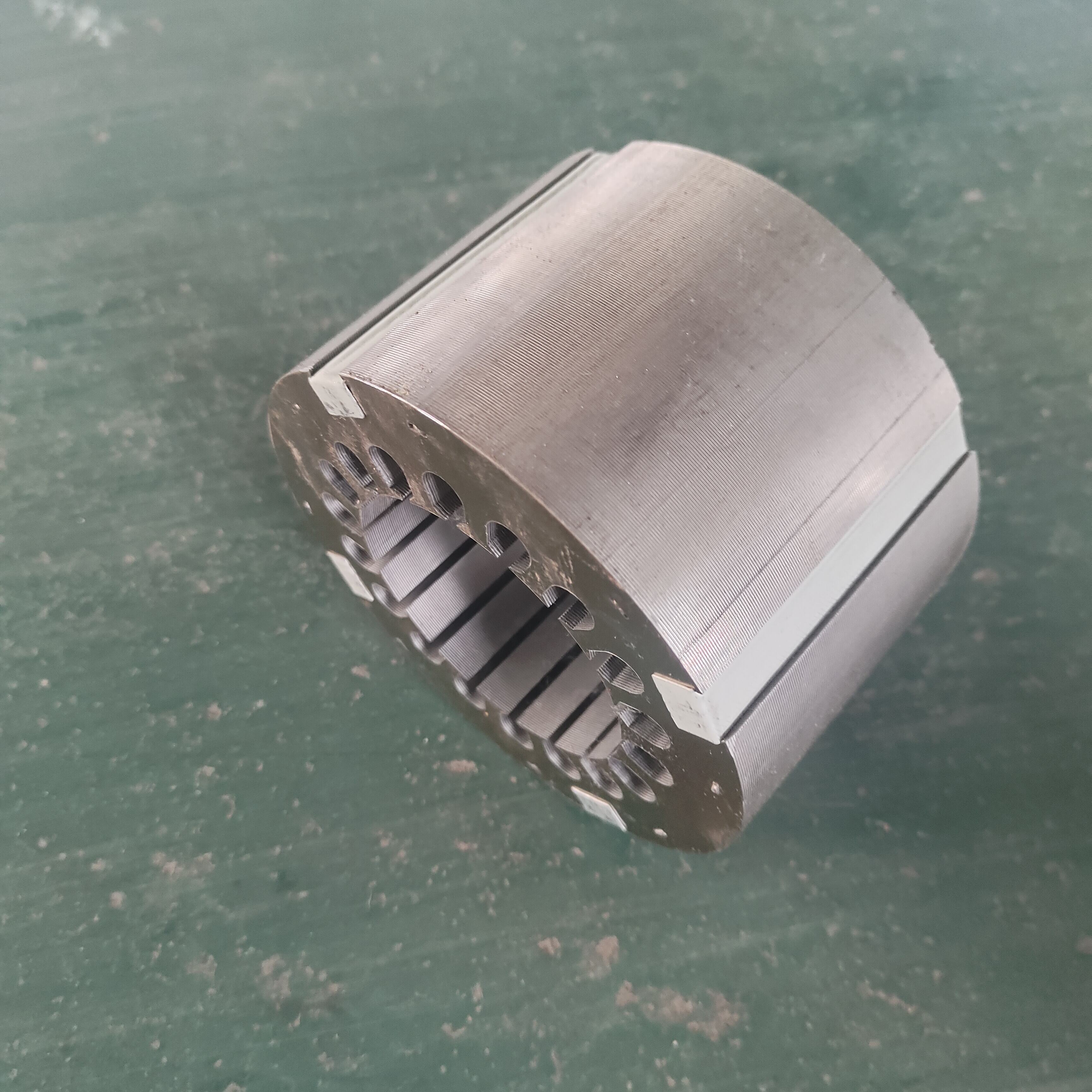

rotor factory

A rotor factory represents a specialized manufacturing facility dedicated to producing high-precision rotating components essential for various industrial applications. These state-of-the-art facilities focus on creating rotors used in electric motors, generators, turbines, compressors, and numerous other mechanical systems that require reliable rotational motion. The rotor factory employs advanced machining technologies, precision engineering processes, and quality control systems to ensure each component meets stringent performance standards. Modern rotor factory operations integrate computer-controlled manufacturing equipment, automated assembly lines, and sophisticated testing protocols to deliver consistent results. The primary function of a rotor factory involves transforming raw materials such as steel, aluminum, copper, and specialized alloys into precisely engineered rotating assemblies. These components undergo multiple manufacturing stages including casting, forging, machining, balancing, and finishing processes. Advanced rotor factory facilities utilize CNC machining centers, multi-axis lathes, grinding machines, and electrical discharge machining equipment to achieve tight tolerances and superior surface finishes. Quality assurance remains paramount in rotor factory operations, with dimensional inspection, material testing, vibration analysis, and performance validation conducted throughout production cycles. The technological features of a modern rotor factory include automated material handling systems, real-time production monitoring, predictive maintenance capabilities, and integrated enterprise resource planning systems. These facilities serve diverse industries including automotive, aerospace, energy generation, HVAC systems, industrial automation, and renewable energy sectors. The rotor factory produces components ranging from small precision rotors for electronic devices to massive industrial rotors for power generation equipment, demonstrating remarkable versatility and technical capability in meeting varied customer requirements across multiple market segments.