Versatile Applications Across Multiple Industries

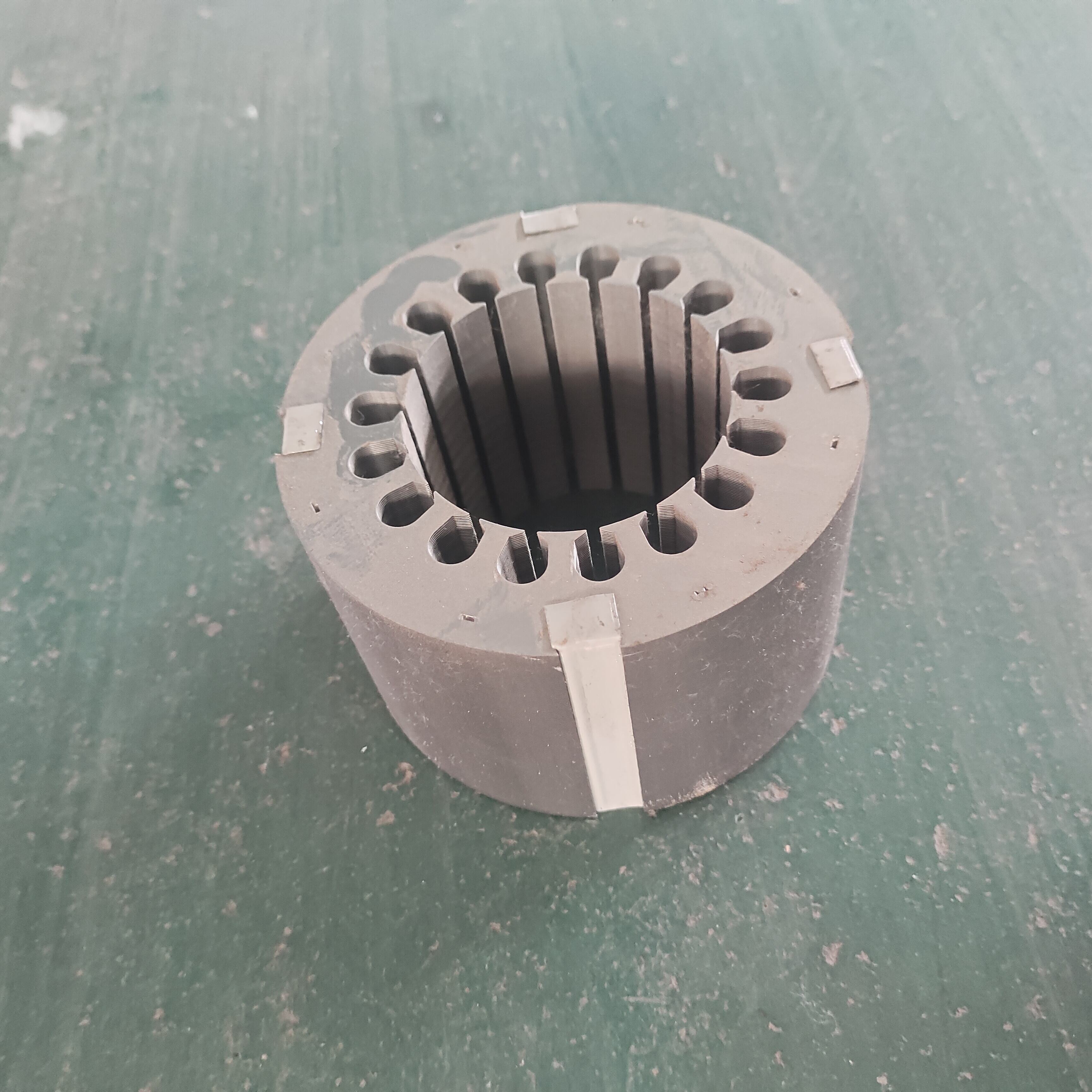

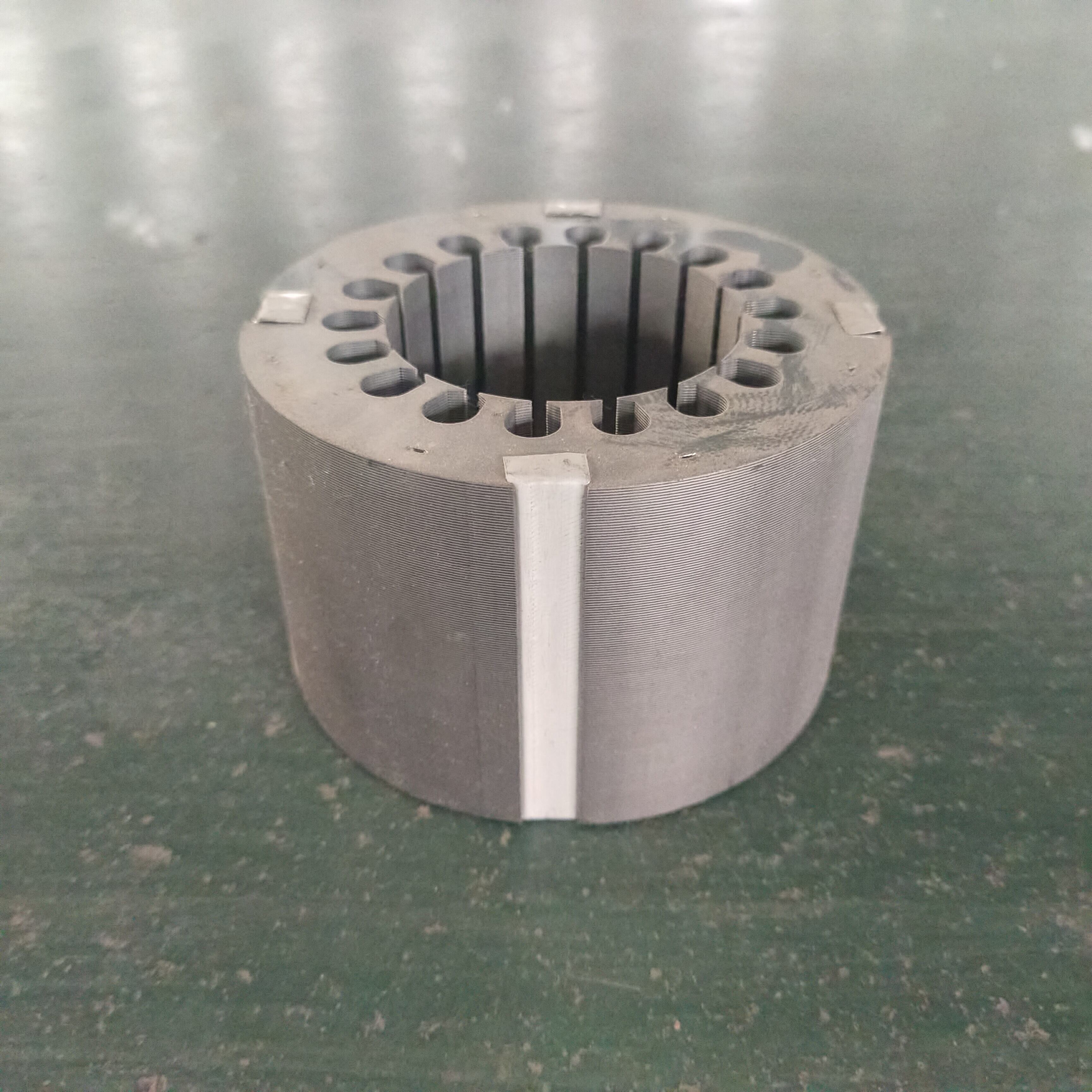

The remarkable versatility of rotor in stock makes it an indispensable component across a wide spectrum of industrial applications, demonstrating exceptional adaptability to diverse operational environments and performance requirements. In the power generation sector, rotor in stock units serve as fundamental components in steam turbines, gas turbines, and hydroelectric generators, where they must withstand extreme temperatures, high pressures, and continuous operation for extended periods. The rotor in stock design incorporates specialized features that enable reliable performance under these demanding conditions, including advanced cooling systems, corrosion-resistant materials, and precision balancing for vibration-free operation. Renewable energy applications represent a growing market for rotor in stock components, particularly in wind turbine generators where these units must efficiently convert variable wind speeds into consistent electrical output. The rotor in stock used in wind energy applications features unique design characteristics optimized for variable speed operation and enhanced durability to withstand harsh environmental conditions. Manufacturing industries rely heavily on rotor in stock components for motors driving production equipment, conveyors, pumps, and compressors that form the backbone of modern industrial operations. The rotor in stock provides the reliable mechanical power transmission necessary for maintaining consistent production schedules and meeting quality standards. Automotive applications utilize specialized rotor in stock designs in electric vehicle motors, alternators, and various auxiliary systems that require compact, efficient, and reliable rotating components. The aerospace industry demands rotor in stock units that meet stringent weight, reliability, and performance criteria for aircraft engines, avionics cooling systems, and flight control actuators. Each rotor in stock application requires specific engineering considerations including operating speed ranges, torque requirements, environmental conditions, and safety factors. The versatility of rotor in stock designs allows manufacturers to customize specifications while maintaining the benefits of standardized production processes, resulting in cost-effective solutions that meet precise application requirements.