ספקי רוטור

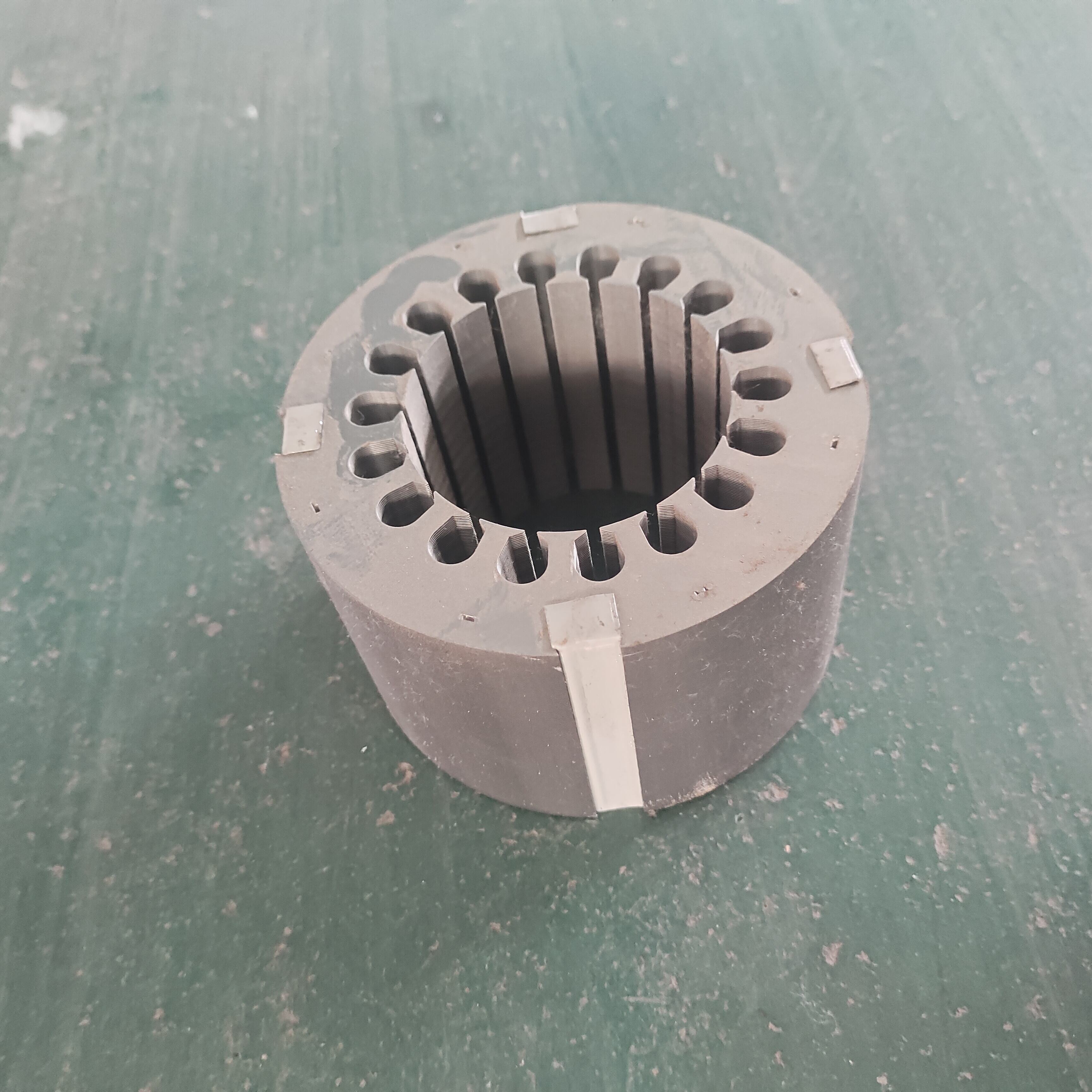

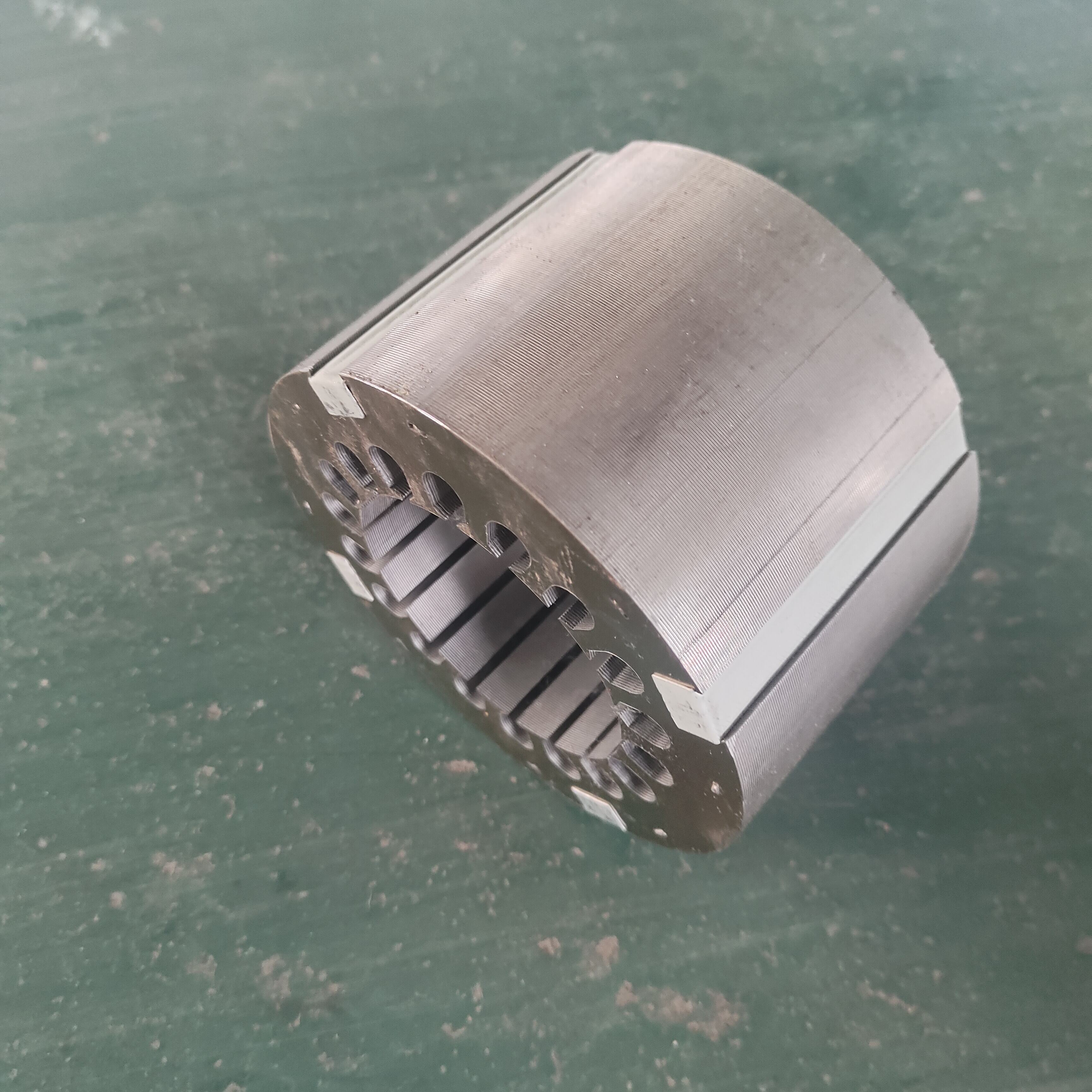

ספקים של רוטורים ממלאים תפקיד חשוב בסביבה התעשייתית המודרנית, כאשר הם מספקים רכיבים מסתובבים חיוניים שמאפשרים פעולה של אינספור מכונות ומערכות בתחומים שונים. יצרנים מתמחים אלו מתמקדים בעיצוב, ייצור והפצה של רוטורים המשמשים ליבה של מנועים חשמליים, מחוללים, טורבינות וכלים מסתובבים אחרים. הפונקציה העיקרית של ספקי רוטורים הולכת מעבר לייצור פשוט, והיא כוללת פתרונות הנדסיים מקיפים הכוללים שירותי עיצוב מותאם אישית, עיבוד במדוייק, פעולות איזון ובקרת איכות באמצעות בדיקות. ספקי רוטורים מובילים משתמשים בטכנולוגיות ייצור מתקדמות כגון מרכזי עיבוד ממוחשבים, מערכות כריכה אוטומטיות וציוד איזון מתוחכם, כדי להבטיח שהמוצרים שלהם עומדים בדרישות ביצועים קפדניות. חברות אלו מציעות בדרך כלל טווח מגוון של סוגי רוטורים, כולל רוטורים בעלי סל תושטots עבור מנועי השראה, רוטורים כרוכים עבור מנועי טבעת החלקה, רוטורים עם מגנט קבוע עבור מכונות סינכרוניות, ורוטורים מיוחדים ליישומים במהירויות גבוהות. התכונות הטכנולוגיות של ספקי רוטורים מודרניים כוללות תהליכי בחירת חומרים מתקדמים, תוך שימוש בפלדות חשמליות מדרגה גבוהה, סגסוגות נחושת וחומרי בידוד מתקדמים, על מנת למקסם את הביצועים האלקטרו-מגנטיים ואת ניהול החום. רבים מספקי הרטורים השקיעו רבות במרכזי מחקר ופיתוח, שם הם ממשיכים להמציא ולשפר את יעילות הרוטורים, להפחית רמות רעש ולהגביר עמידות בתנאי עבודה קיצוניים. היישומים של ספקי רוטורים משתרעים על פני מגוון רחב של תעשיות, מהרכב, תעופה וחלל, דרך אנרגיה מתחדשת ועד אוטומציה תעשייתית. במגזר הרכב, ספקי רוטורים מספקים רכיבים למנועי רכב חשמלי, דחיפה היברידית, וכן אלטרנטורים ומתחילים מסורתיים. תעשית האנרגיה המתחדשת סומכת במידה רבה על ספקי רוטורים לצורך מחוללי טורבינות רוח, טורבינות הידרו-אלקטריות ומערכות עקיבה לשמש. ליישומים תעשייתיים gehören משאבות, דחסים, מערכות מסועים וציוד ייצור, שבהן מכשור מסתובב אמין הוא חיוני להצלחת הפעילות.