Flexible Integration and Application Versatility

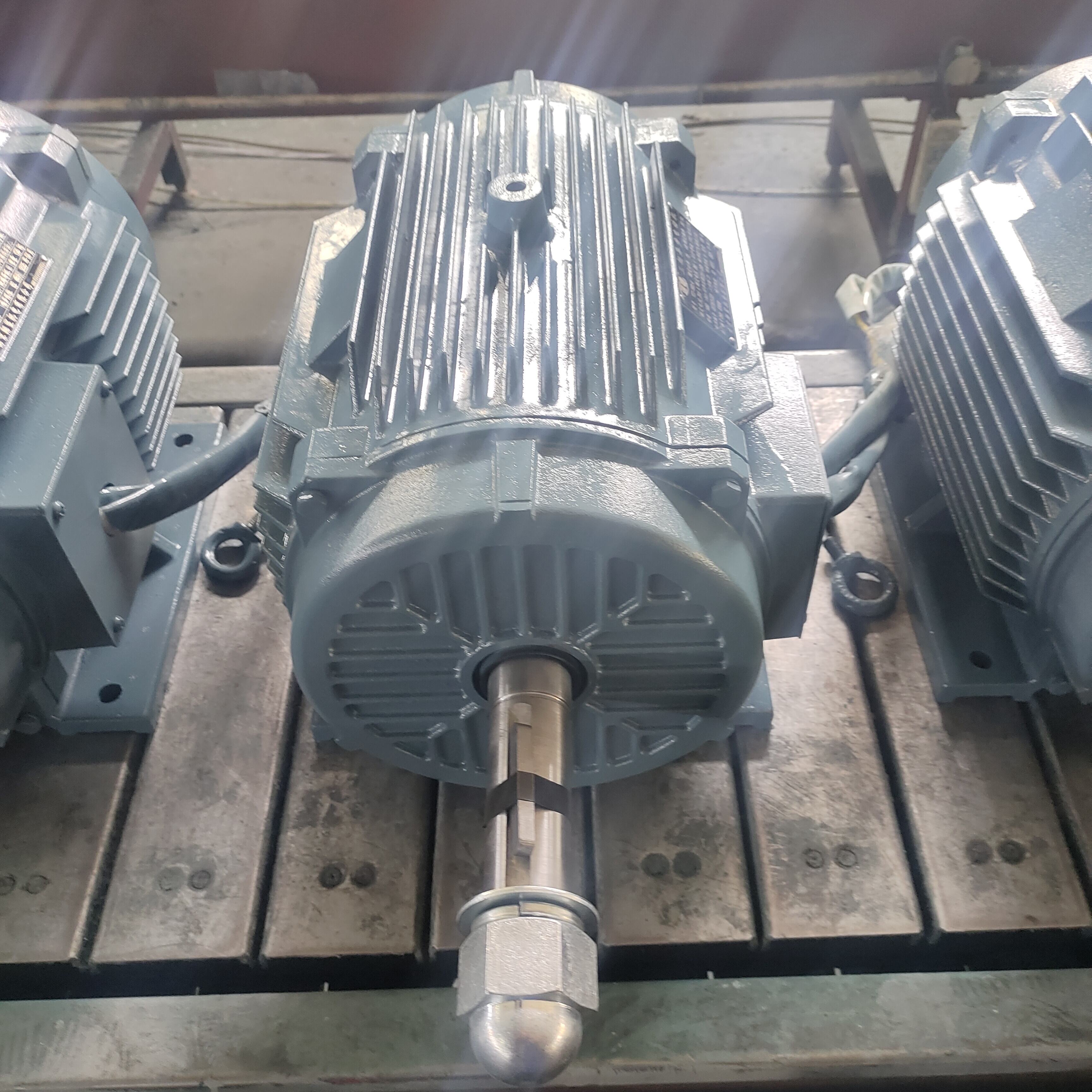

The integration flexibility of customized asynchronous motors provides unprecedented versatility for diverse industrial applications, enabling seamless incorporation into existing systems while accommodating unique operational requirements. This adaptability stems from comprehensive design approaches that consider mechanical interfaces, electrical connections, and control system compatibility from the initial specification phase. The customized asynchronous motor can incorporate specialized mounting configurations, including custom flanges, foot arrangements, and shaft extensions that facilitate direct integration with driven equipment. Flexible electrical specifications allow for adaptation to various voltage levels, frequency requirements, and control system interfaces, ensuring compatibility with existing infrastructure while providing upgrade paths for future enhancements. Advanced terminal box designs accommodate different connection methods, conduit entries, and environmental protection requirements, while maintaining easy access for maintenance and inspection procedures. The customized asynchronous motor supports various control strategies, from simple across-the-line starting to sophisticated variable frequency drive applications with integrated feedback systems. Specialized encoder mounting provisions, thermal monitoring capabilities, and vibration sensing options enable comprehensive condition monitoring and predictive maintenance programs. The design flexibility extends to environmental considerations, with options for explosion-proof enclosures, marine-grade protection, and specialized coatings that resist corrosive atmospheres. Custom cooling arrangements, including forced air, water cooling, or specialized heat exchangers, ensure optimal performance in challenging thermal environments. The customized asynchronous motor can integrate with building automation systems, process control networks, and remote monitoring platforms through various communication protocols. Modular design approaches enable field modifications and upgrades without complete motor replacement, providing long-term flexibility as application requirements evolve. This comprehensive integration capability ensures that customized asynchronous motors deliver optimal performance while minimizing installation complexity and maximizing operational efficiency across diverse industrial sectors and specialized applications.