Integrasi Fleksibel dan Versatilitas Aplikasi

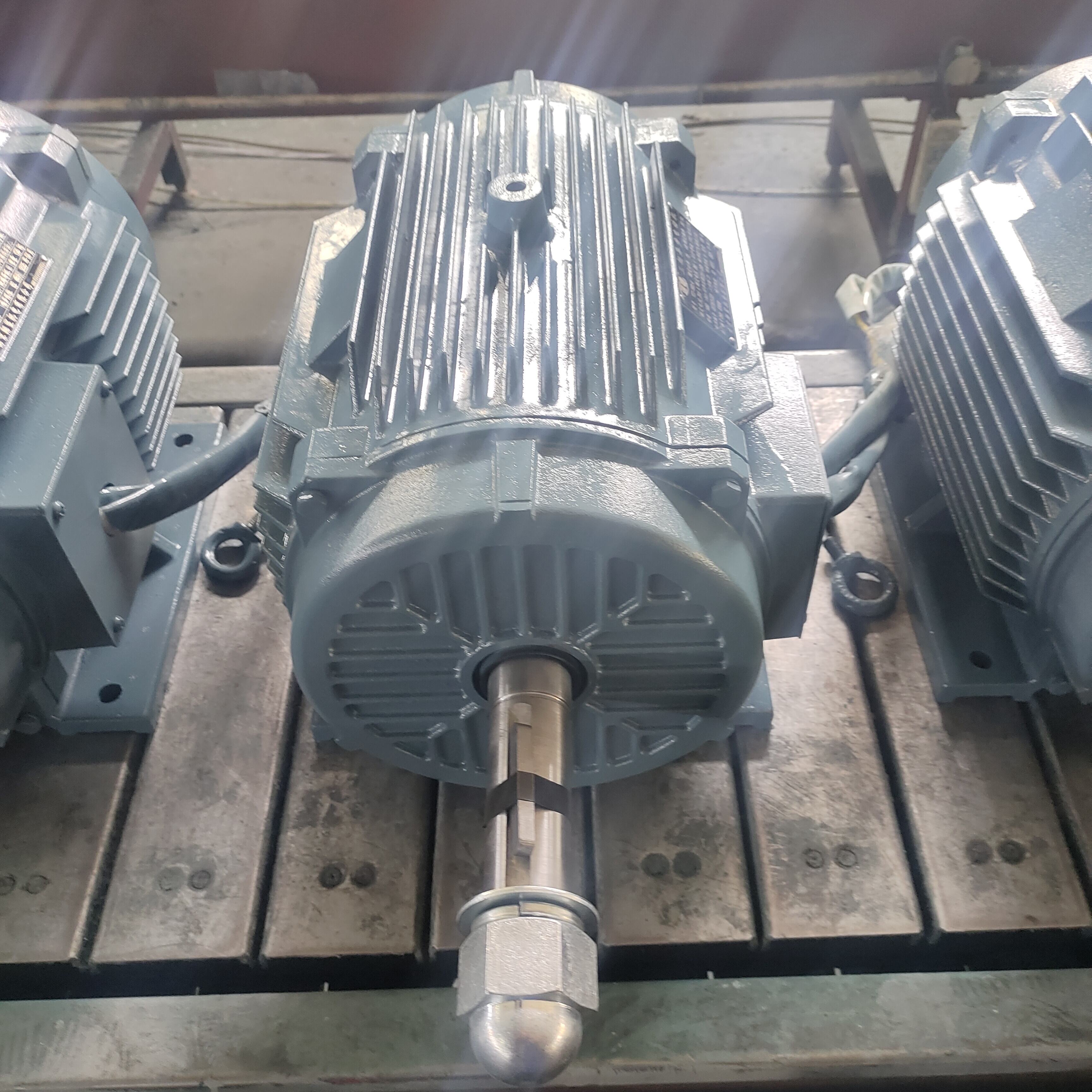

Fleksibilitas integrasi motor asinkron khusus memberikan versatilitas yang belum pernah terjadi sebelumnya untuk berbagai aplikasi industri, memungkinkan integrasi mulus ke dalam sistem yang sudah ada sambil menyesuaikan kebutuhan operasional yang unik. Adaptabilitas ini berasal dari pendekatan desain komprehensif yang mempertimbangkan antarmuka mekanis, koneksi listrik, dan kompatibilitas sistem kontrol sejak fase spesifikasi awal. Motor asinkron khusus dapat mencakup konfigurasi pemasangan khusus, termasuk flensa khusus, susunan kaki, dan perpanjangan poros yang memudahkan integrasi langsung dengan peralatan yang digerakkan. Spesifikasi listrik yang fleksibel memungkinkan penyesuaian terhadap berbagai tingkat tegangan, kebutuhan frekuensi, dan antarmuka sistem kontrol, memastikan kompatibilitas dengan infrastruktur yang ada sekaligus menyediakan jalur peningkatan untuk pengembangan di masa depan. Desain kotak terminal canggih mampu menampung berbagai metode koneksi, masukan saluran kabel, dan persyaratan perlindungan lingkungan, sekaligus tetap memudahkan akses untuk prosedur pemeliharaan dan inspeksi. Motor asinkron khusus mendukung berbagai strategi kontrol, mulai dari penghidupan langsung hingga aplikasi drive frekuensi variabel canggih dengan sistem umpan balik terintegrasi. Penyediaan pemasangan encoder khusus, kemampuan pemantauan termal, dan opsi sensor getaran memungkinkan pemantauan kondisi secara komprehensif serta program pemeliharaan prediktif. Fleksibilitas desain juga mencakup pertimbangan lingkungan, dengan pilihan enclosure tahan ledakan, proteksi kelas maritim, dan lapisan khusus yang tahan terhadap atmosfer korosif. Pengaturan pendinginan khusus, termasuk udara paksa, pendinginan air, atau penukar panas khusus, memastikan kinerja optimal dalam lingkungan termal yang menantang. Motor asinkron khusus dapat terintegrasi dengan sistem otomasi bangunan, jaringan kontrol proses, dan platform pemantauan jarak jauh melalui berbagai protokol komunikasi. Pendekatan desain modular memungkinkan modifikasi dan peningkatan di lapangan tanpa harus mengganti seluruh motor, memberikan fleksibilitas jangka panjang seiring dengan perubahan kebutuhan aplikasi. Kemampuan integrasi yang komprehensif ini memastikan bahwa motor asinkron khusus memberikan kinerja optimal sekaligus meminimalkan kompleksitas instalasi dan memaksimalkan efisiensi operasional di berbagai sektor industri dan aplikasi khusus.