Fleksibel integrasjon og anvendelsesmangfold

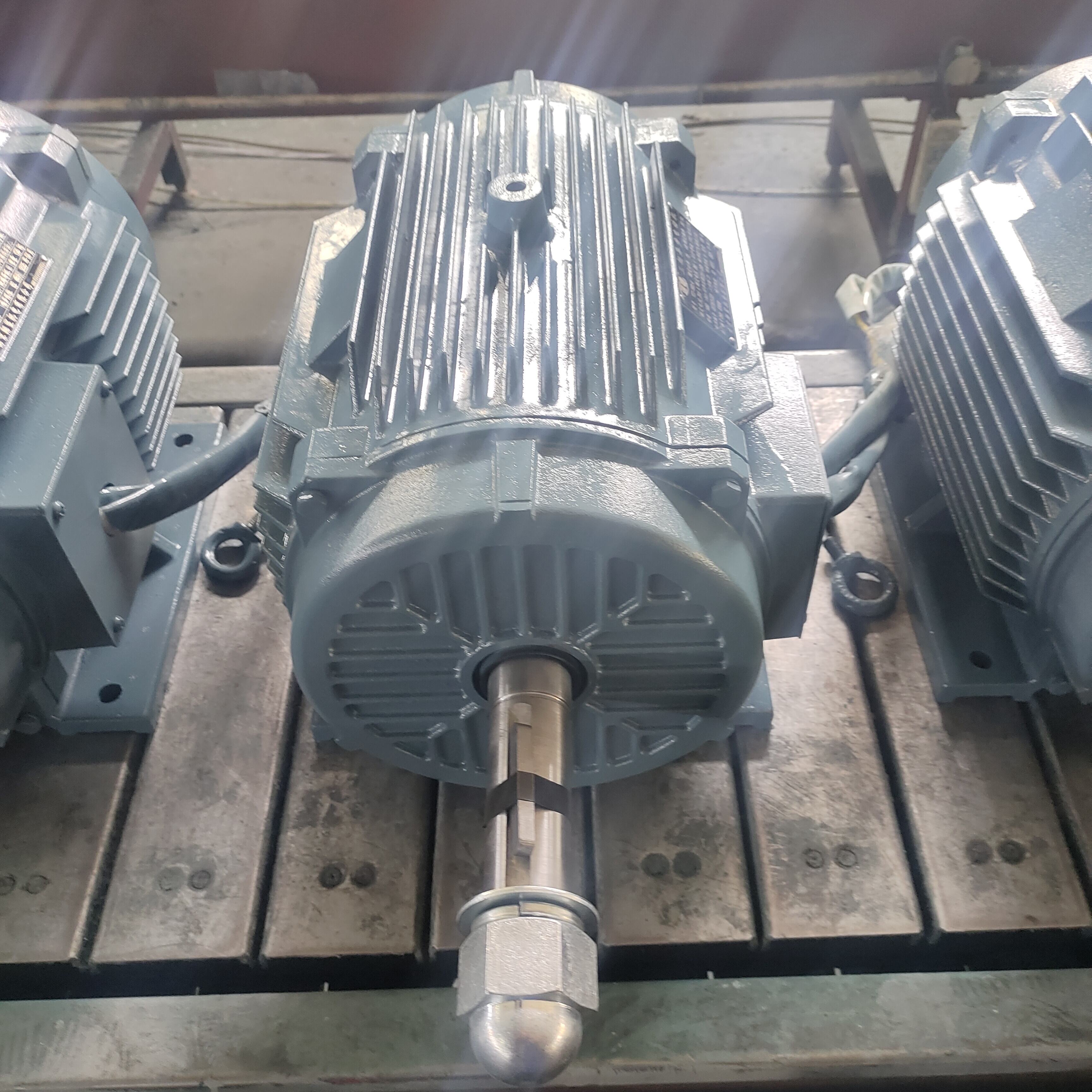

Integreringsfleksibiliteten til skreddersydde asynkrone motorer gir ubegrenset mangfoldighet for ulike industrielle applikasjoner, og muliggjør sømløs integrasjon i eksisterende systemer samtidig som de imøtekommer spesielle driftskrav. Denne tilpasningsevnen stammer fra omfattende designmetoder som tar hensyn til mekaniske grensesnitt, elektriske tilkoblinger og kompatibilitet med kontrollsystemer allerede fra den innledende spesifikasjonsfasen. Den skreddersydde asynkrone motoren kan inneholde spesialiserte monteringskonfigurasjoner, inkludert egendefinerte flenser, fotanordninger og akslingforlengelser som forenkler direkte integrasjon med drevet utstyr. Fleksible elektriske spesifikasjoner tillater tilpasning til ulike spenningsnivåer, frekvenskrav og grensesnitt for kontrollsystemer, og sikrer dermed kompatibilitet med eksisterende infrastruktur samtidig som det legges opp til oppgraderinger i fremtiden. Avanserte klemkasse-design håndterer ulike tilkoblingsmetoder, kabelgjennomføringer og krav til miljøbeskyttelse, samtidig som de holder god tilgang for vedlikehold og inspeksjonsprosedyrer. Den skreddersydde asynkrone motoren støtter ulike styringsstrategier, fra enkel direktestart til sofistikerte variabelfrekvensdriftsanvendelser med integrerte tilbakemeldingssystemer. Spesialiserte plasseringsløsninger for enkodere, termisk overvåkningskapasitet og vibrasjonsmålealternativer gjør det mulig med omfattende tilstandsmonitorering og prediktivt vedlikehold. Designfleksibiliteten går videre til miljømessige hensyn, med alternativer for eksplosjonsikre kabinetter, skipsklasse beskyttelse og spesialbelegg som tåler korrosive atmosfærer. Skreddersydde kjøleanordninger, inkludert tvungen luft, vannkjøling eller spesialiserte varmevekslere, sikrer optimal ytelse i krevende termiske miljøer. Den skreddersydde asynkrone motoren kan integreres med bygningsautomatiseringssystemer, prosesskontrollnettverk og fjernovervåkningsplattformer via ulike kommunikasjonsprotokoller. Modulære designmetoder gjør det mulig med feltmodifikasjoner og oppgraderinger uten full motorutskifting, og gir langsiktig fleksibilitet etter hvert som applikasjonskravene utvikler seg. Denne omfattende integrasjonsmuligheten sikrer at skreddersydde asynkrone motorer leverer optimal ytelse samtidig som installasjonskompleksiteten minimeres og driftseffektiviteten maksimeres over ulike industrielle sektorer og spesialiserte anvendelser.