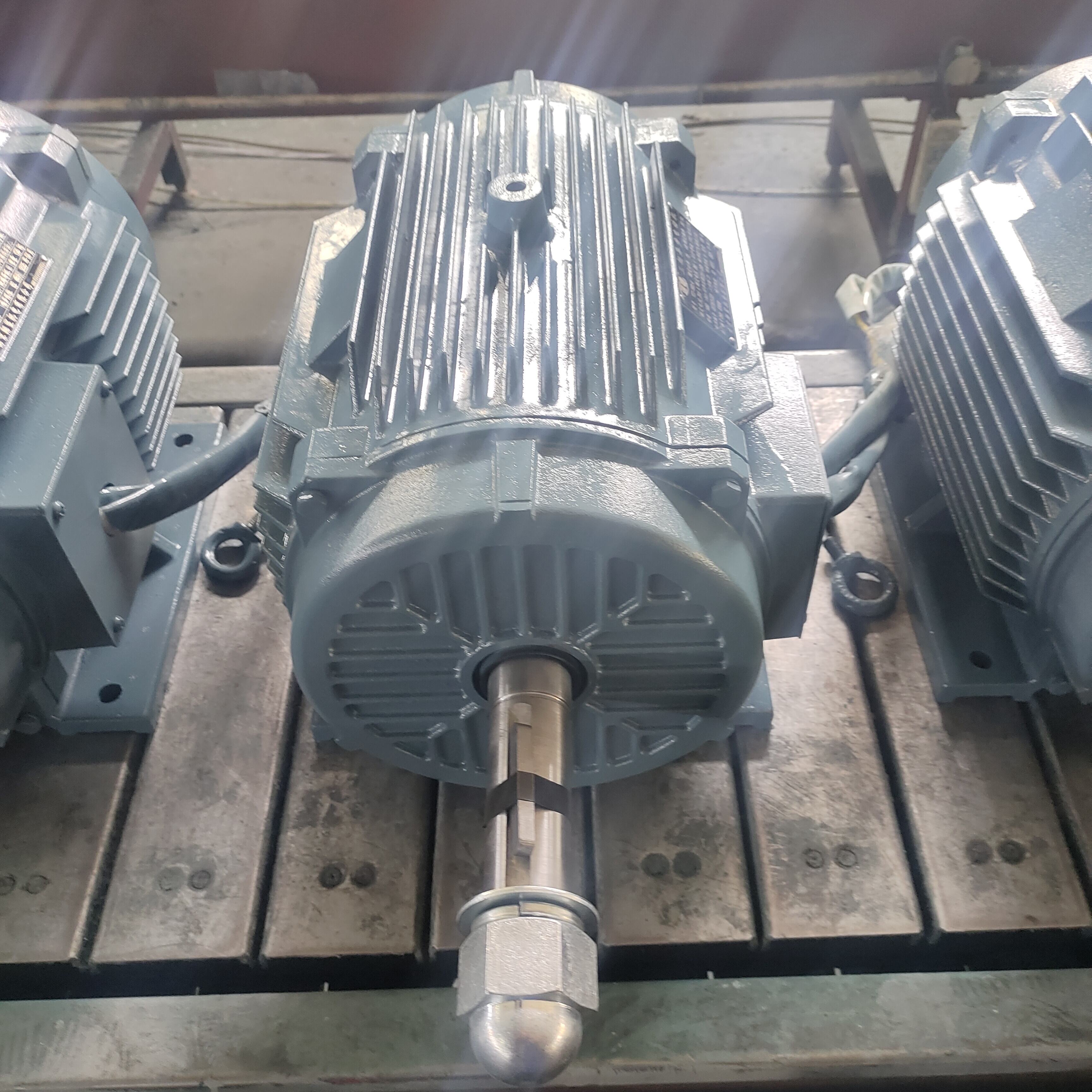

discount asynchronous motor

The discount asynchronous motor represents a revolutionary advancement in electric motor technology, delivering exceptional performance at an affordable price point. These motors operate on the principle of electromagnetic induction, where the rotor rotates at a speed slightly less than the rotating magnetic field produced by the stator windings. This speed difference, known as slip, enables the motor to generate torque and provide reliable mechanical power output. The discount asynchronous motor incorporates advanced design elements that optimize efficiency while maintaining cost-effectiveness, making it an ideal solution for various industrial and commercial applications. These motors feature robust construction with high-quality materials that ensure long-lasting performance even in demanding operational environments. The technological framework includes precision-engineered rotor bars, optimized stator windings, and enhanced cooling systems that work together to deliver superior operational characteristics. The motor's design incorporates variable frequency drive compatibility, allowing for precise speed control and energy optimization across different load conditions. Modern discount asynchronous motors utilize advanced insulation materials and improved bearing systems that significantly extend operational lifespan while reducing maintenance requirements. The integrated protection features include thermal overload protection, voltage fluctuation resistance, and moisture-resistant enclosures that safeguard internal components from environmental hazards. These motors excel in applications requiring consistent torque delivery, such as conveyor systems, pumps, fans, compressors, and manufacturing equipment. The discount asynchronous motor's versatility extends to multiple mounting configurations, enabling seamless integration into existing mechanical systems without extensive modifications. Advanced manufacturing processes ensure consistent quality control and dimensional accuracy, resulting in motors that deliver predictable performance characteristics across production batches. The cost-effective nature of these motors makes them particularly attractive for budget-conscious projects without compromising on essential performance parameters or reliability standards.