asynchronous motor manufacturers

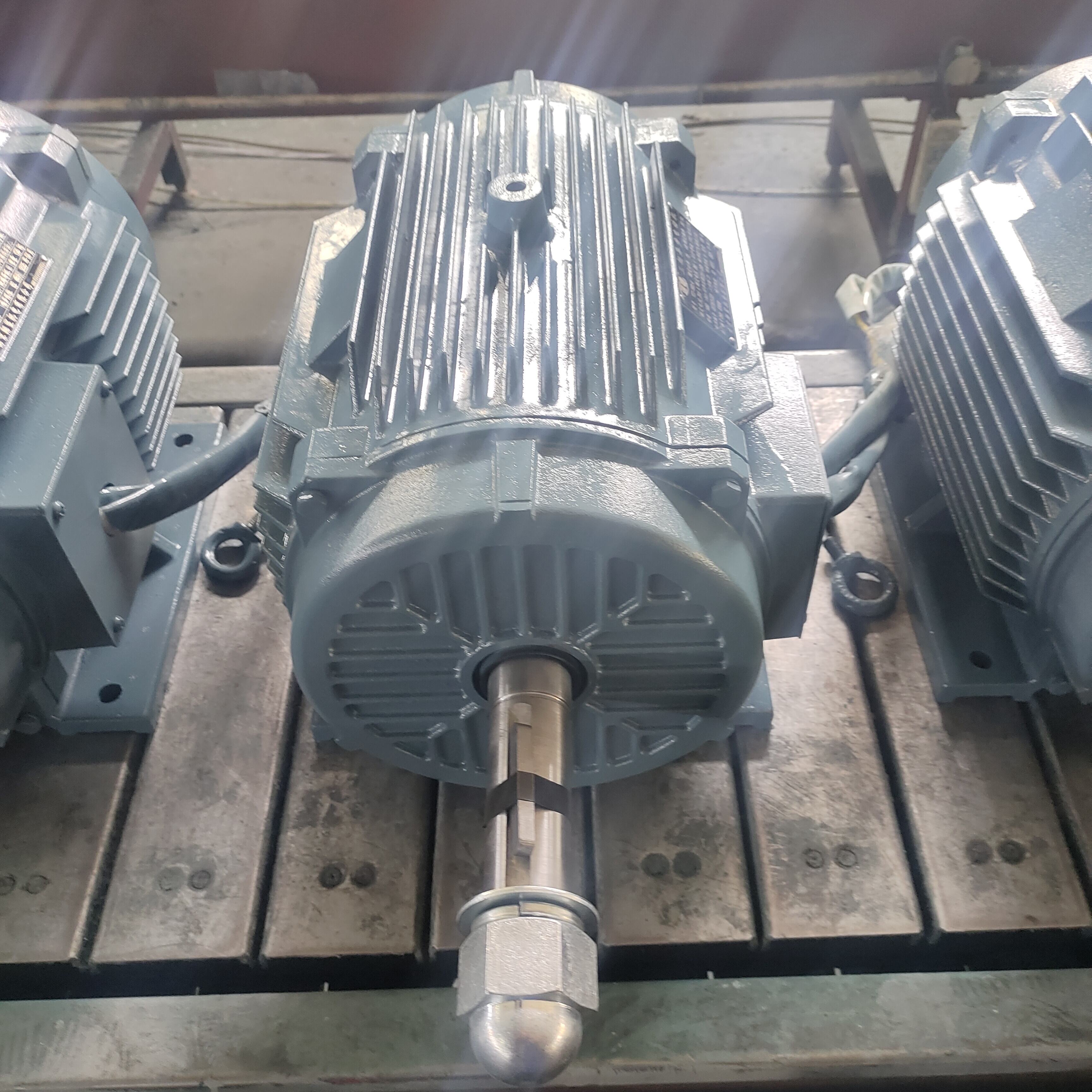

Asynchronous motor manufacturers represent the backbone of industrial automation and power transmission systems worldwide. These specialized companies design, develop, and produce electric motors that operate on the principle of electromagnetic induction, where the rotor rotates at a speed slightly less than the synchronous speed of the rotating magnetic field. Leading asynchronous motor manufacturers focus on creating robust, efficient, and versatile motors that serve diverse industrial applications across multiple sectors. The primary function of these motors centers on converting electrical energy into mechanical energy through electromagnetic induction, making them essential components in manufacturing processes, HVAC systems, pumps, compressors, and conveyor systems. Modern asynchronous motor manufacturers incorporate advanced technological features including variable frequency drive compatibility, high-efficiency designs meeting international standards, and smart monitoring capabilities. These motors typically feature squirrel cage or wound rotor designs, with manufacturers offering customizable specifications for voltage ratings, power outputs, and environmental conditions. The technological advancement in asynchronous motor manufacturing has led to the development of energy-efficient models that comply with IE3 and IE4 efficiency standards, reducing operational costs and environmental impact. Contemporary asynchronous motor manufacturers utilize computer-aided design systems, precision manufacturing techniques, and quality control processes to ensure consistent performance and reliability. Applications span across industries including automotive manufacturing, food processing, textile production, water treatment facilities, mining operations, and renewable energy systems. These manufacturers serve both original equipment manufacturers and end-users, providing comprehensive solutions from standard catalog products to custom-engineered motors. The global market for asynchronous motor manufacturers continues expanding due to increasing industrial automation, energy efficiency requirements, and sustainable manufacturing practices.