asynkronmotorprodusenter

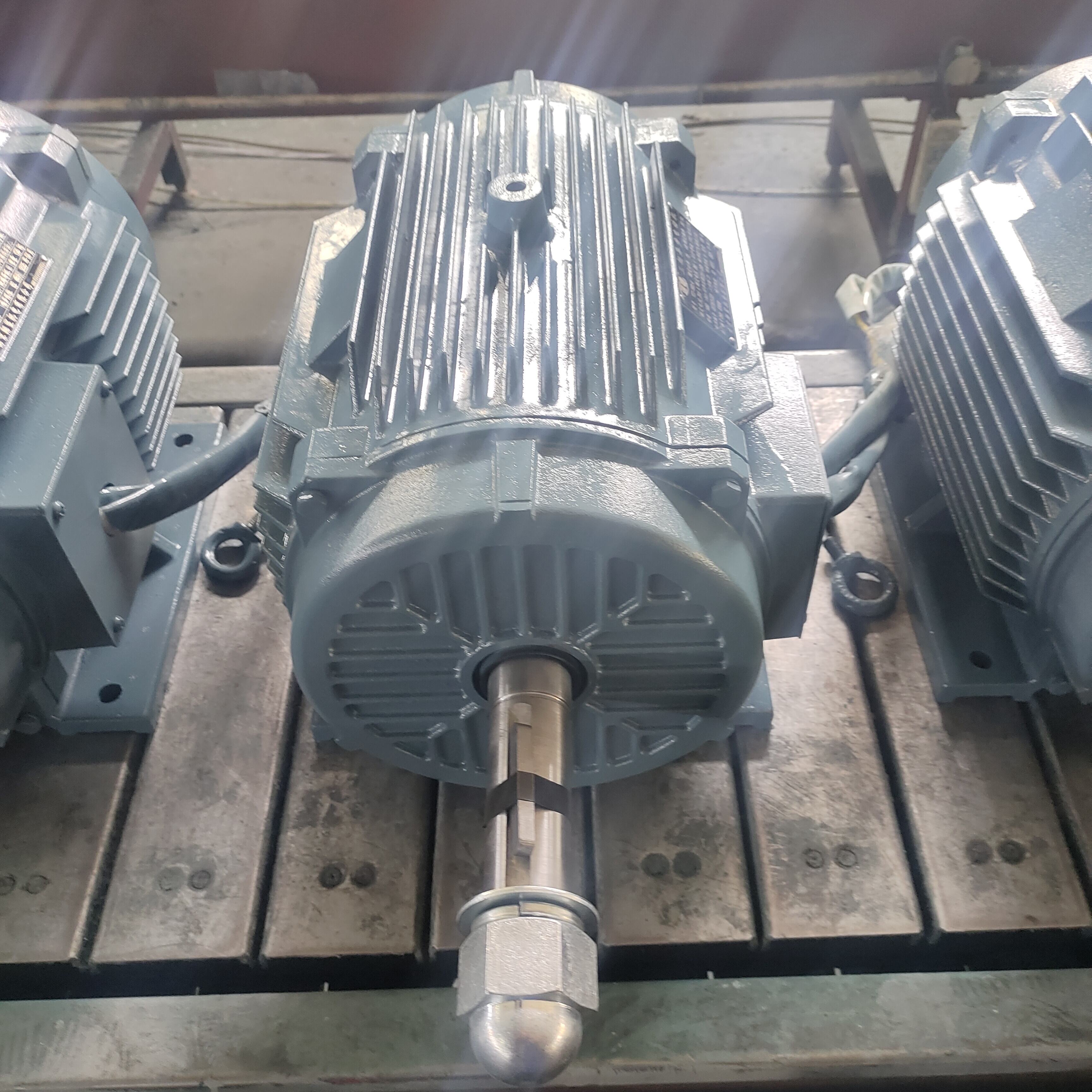

Asynkrone motorproducenter udgør rygraden i industrielle automatiserings- og kraftoverføringssystemer verden over. Disse specialiserede virksomheder designer, udvikler og producerer elmotorer, der fungerer på princippet om elektromagnetisk induktion, hvor rotoren roterer med en hastighed, der er lidt lavere end den synkrone hastighed for det roterende magnetfelt. Ledende producenter af asynkrone motorer fokuserer på at skabe robuste, effektive og alsidige motorer, som anvendes i mange forskellige industrielle applikationer på tværs af flere sektorer. Hovedformålet med disse motorer er at omdanne elektrisk energi til mekanisk energi via elektromagnetisk induktion, hvilket gør dem til uundværlige komponenter i produktionsprocesser, HVAC-systemer, pumper, kompressorer og transportbånd. Moderne producenter af asynkrone motorer integrerer avancerede teknologiske funktioner såsom kompatibilitet med variabel frekvensstyring, højeffektivitetsdesign, der opfylder internationale standarder, samt smarte overvågningsfunktioner. Disse motorer har typisk rotorudformning i form af 'short-circuit' (kortslutningsløber) eller viklet rotor, og producenterne tilbyder skræddersyede specifikationer for spændingsklasser, effektydelser og miljøforhold. Den teknologiske udvikling inden for produktion af asynkrone motorer har ført til energieffektive modeller, der overholder effektivitetsstandarderne IE3 og IE4, hvilket reducerer driftsudgifter og miljøpåvirkning. Nutidige producenter af asynkrone motorer anvender computerstøttet design (CAD), præcisionsfremstillingsmetoder og kvalitetskontrolprocesser for at sikre konstant ydelse og pålidelighed. Anvendelsesområder dækker industrier såsom bilproduktion, fødevareforarbejdning, tekstilproduktion, renseanlæg, minedrift og systemer til vedvarende energi. Producenterne leverer både til originale udstyrsproducenter (OEM'er) og slutbrugere og tilbyder omfattende løsninger – fra standardprodukter i kataloget til skræddersyede motorer. Det globale marked for producenter af asynkrone motorer fortsætter med at vokse på grund af stigende industrialisering, krav om energieffektivitet og bæredygtige produktionsmetoder.